Sulfonic acid type semi-bright pure-tin electroplating liquid

A tin electroplating, sulfonic acid type technology, applied in the field of sulfonic acid type semi-bright pure tin electroplating solution, can solve the problems of high cost of fluoroborate tin plating solution, poor dispersibility of the plating solution, easy hydrolysis of divalent tin, etc. Achieve high production efficiency, fast deposition speed and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

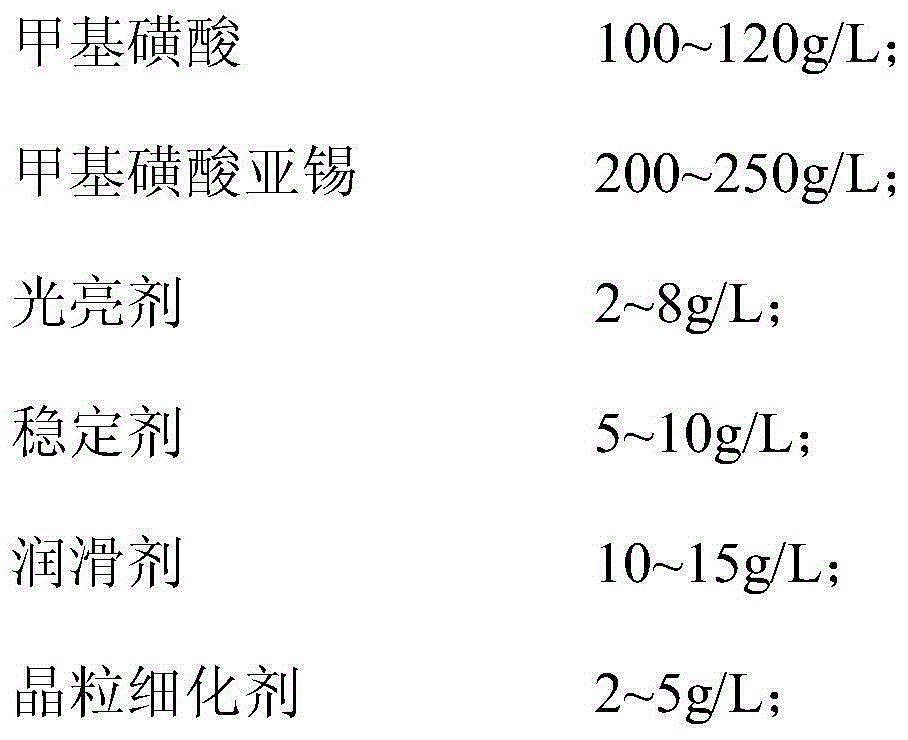

[0023] The sulfonic acid type semi-bright pure tin electroplating solution of this implementation comprises the component of following concentration:

[0024]

[0025] Stabilizers include components at the following concentrations:

[0026] Ethanol 2.5mol / L;

[0027] Sodium sulfite 3.0mol / L;

[0028] Ferrous sulfate 0.5mol / L.

[0029] The brightener is β-naphthol ethoxylate, the lubricant is nonylphenol polyoxyethylene ether NP series, and the lubricant is specifically one of NP-10, NP-12, NP-40 or a mixture of at least two , such as NP-10, the grain refiner is coconut oil fatty alcohol polyoxyethylene ether.

[0030] The sulfonic acid type semi-bright pure tin electroplating solution of the above-mentioned embodiment adopts tin protosulfonate as the main salt, and the synergistic effect of brightener, stabilizer, alkylsulfonic acid, wetting agent, grain refiner and other components The components in the sulfonic acid type semi-bright pure tin electroplating solution ha...

Embodiment 2

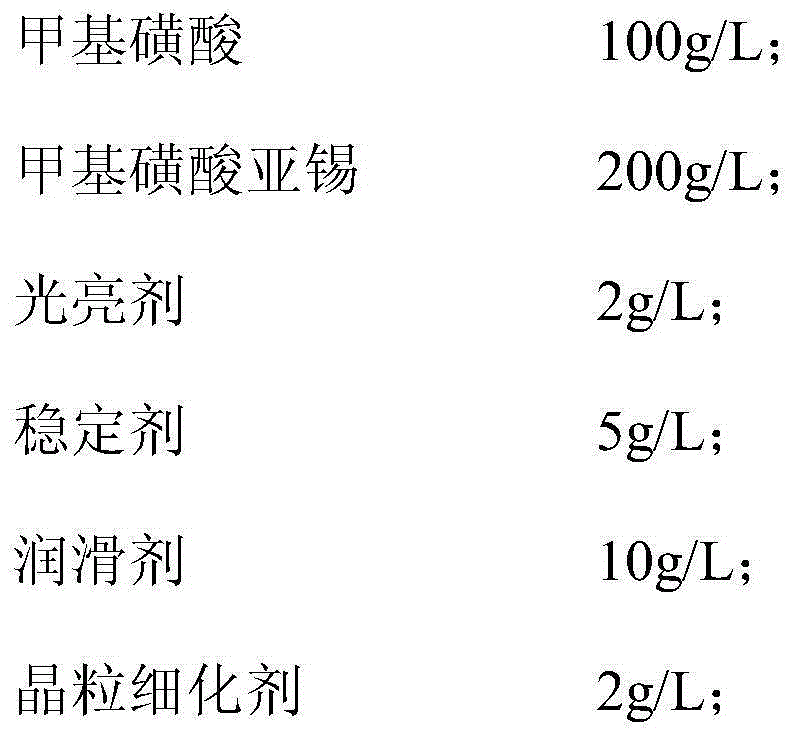

[0032] The sulfonic acid type semi-bright pure tin electroplating solution of this implementation comprises the component of following concentration:

[0033]

[0034] Described stabilizer comprises the component of following concentration:

[0035] Ethanol 3mol / L;

[0036] Sodium sulfite 4mol / L;

[0037] Ferrous sulfate 1mol / L

[0038] The selection of brightener, lubricant and grain refiner in this embodiment refers to Example 1.

Embodiment 3

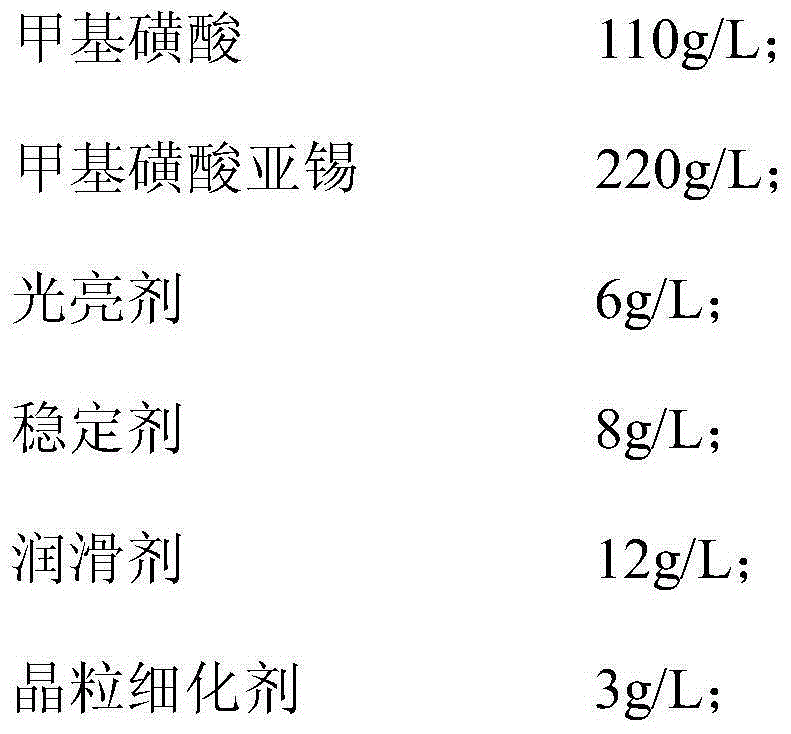

[0040] The sulfonic acid type semi-bright pure tin electroplating solution of this implementation comprises the component of following concentration:

[0041]

[0042]

[0043] Described stabilizer comprises the component of following concentration:

[0044] Ethanol 4mol / L;

[0045] Sodium sulfite 5.0mol / L;

[0046] Ferrous sulfate 1.5mol / L.

[0047] The selection of brightener, lubricant and grain refiner in this embodiment refers to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com