Goggles for power maintenance worker and manufacturing method of goggles

A technology for maintenance personnel and production methods, applied in the field of machinery, can solve problems such as inability to adjust sunlight transmittance, inconvenience for users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

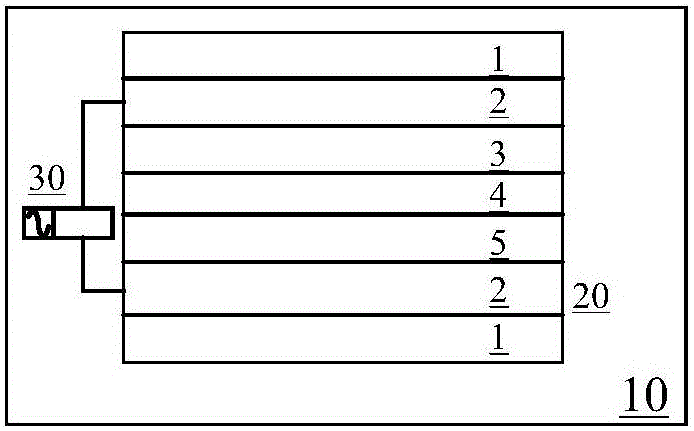

[0066] The frame part 10, the electrochromic device 20 and the controller 30 are assembled.

[0067] Making the electrochromic device 20 includes:

[0068] (1)WO 3 Preparation of nano-film 5 material electrochromic electrode:

[0069] a. Magnetron sputtering fluorine-doped tin oxide (FTO) film 2 on the surface of tempered glass 1 with a specific size, the thickness is about 320nm;

[0070] b. Perform high temperature annealing treatment on it to obtain high-strength FTO conductive glass, and then ultrasonically clean the FTO conductive glass for 15 minutes in the order of ultrapure water, acetone, and ethanol, and dry it for use; then, use the magnetron sputtering method Plating W film on FTO glass with a thickness of 220nm; W film is used as WO 3 The growth source of nanowires;

[0071] c. Prepare a 0.2mol / L sodium tungstate aqueous solution, and then add 3mol / L hydrochloric acid dropwise until no precipitation occurs. The precipitate is washed by centrifugation and dissolved in hydro...

Embodiment 2

[0086] The frame part 10, the electrochromic device 20 and the controller 30 are assembled.

[0087] Making the electrochromic device 20 includes:

[0088] (1)WO 3 Preparation of nano-film 5 material electrochromic electrode:

[0089] a. Magnetron sputtering fluorine-doped tin oxide (FTO) film 2 on the surface of tempered glass 1 with a specific size, the thickness is about 360nm;

[0090] b. Perform high temperature annealing treatment on it to obtain high-strength FTO conductive glass, and then ultrasonically clean the FTO conductive glass for 15 minutes in the order of ultrapure water, acetone, and ethanol, and dry it for use; then, use the magnetron sputtering method Plating W film on FTO glass with a thickness of 200nm; W film is used as WO 3 The growth source of nanowires;

[0091] c. Prepare a 0.2mol / L sodium tungstate aqueous solution, and then add 3mol / L hydrochloric acid dropwise until no precipitation occurs. The precipitate is washed by centrifugation and dissolved in hydro...

Embodiment 3

[0106] The frame part 10, the electrochromic device 20 and the controller 30 are assembled.

[0107] Making the electrochromic device 20 includes:

[0108] (1)WO 3 Preparation of nano-film 5 material electrochromic electrode:

[0109] a. Magnetron sputtering fluorine-doped tin oxide (FTO) film on the surface of tempered glass 1 of specific size, the thickness is about 340nm;

[0110] b. Perform high temperature annealing treatment on it to obtain high-strength FTO conductive glass, and then ultrasonically clean the FTO conductive glass for 15 minutes in the order of ultrapure water, acetone, and ethanol, and dry it for use; then, use the magnetron sputtering method Plating W film on FTO glass with a thickness of 210nm; W film is used as WO 3 The growth source of nanowires;

[0111] c. Prepare a 0.2mol / L sodium tungstate aqueous solution, and then add 3mol / L hydrochloric acid dropwise until no precipitation occurs. The precipitate is washed by centrifugation and dissolved in hydrogen pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com