Processing method for instant peanut vine mixing powder

A processing method and technology of peanut vine, which is applied in the field of processing instant peanut vine powder, can solve the problems of peanut vine powder and achieve the effects of improving health care value, good dispersion uniformity, and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

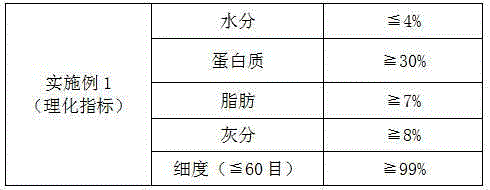

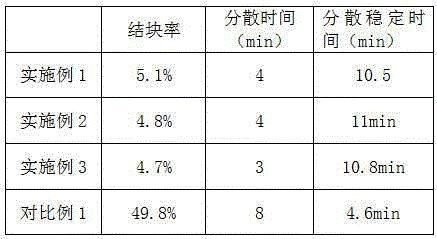

Embodiment 1

[0029] A processing method for instant peanut vine powder, comprising the following steps:

[0030] ( 1) Select fresh and tender peanut vines free from diseases and insect pests, and soak them in clean water for 2 times to remove impurities;

[0031] (2) After washing, the peanut vines are cut into 5-10cm small pieces, and steamed at 100°C for 10 minutes;

[0032] (3) Soak the peanut vines in calcium citrate-citric acid-water solution for 12 hours according to the ratio of material to liquid: 1g:25mL, and then rinse with clean water;

[0033] Described calcium citrate-citric acid-water solution contains 100mL water in every 100mL, 0.1g citric acid and 0.1g calcium citrate;

[0034] (4) Spray the deastringent-treated peanut vines with rice wine (semi-dry rice wine, sugar content 20g / L) and sodium caseinate, which account for 3% of the weight of the peanut vines (after removing impurities), and sodium caseinate according to the mass ratio 6:1 composition of the mixed solution...

Embodiment 2

[0039] A processing method for instant peanut vine powder, comprising the following steps:

[0040] ( 1) Select fresh and tender peanut vines free from diseases and insect pests, and soak them in water for 3 times to remove impurities;

[0041] (2) After washing, the peanut vines are cut into 5-10cm small pieces, and steamed at 120°C for 5 minutes;

[0042] (3) Soak peanut vines in calcium citrate-citric acid-water solution for 12 hours according to the material-to-liquid ratio of 1g:30mL, and then rinse with clean water;

[0043] Described calcium citrate-citric acid-water solution contains 100mL water in every 100mL, 0.1g citric acid and 0.1g calcium citrate;

[0044] (4) Spray the deastringent-treated peanut vines with rice wine (semi-dry rice wine, sugar content 15g / L) and sodium caseinate, which account for 4% of the weight of the peanut vines (after removing impurities), and sodium caseinate according to the mass ratio 6:1 composition of the mixed solution, and then a...

Embodiment 3

[0049] A processing method for instant peanut vine powder, comprising the following steps:

[0050] ( 1) Select fresh and tender peanut vines free from diseases and insect pests, and soak them in water for 3 times to remove impurities;

[0051] (2) After washing, the peanut vines are cut into 5-10cm small pieces, and steamed at 110°C for 8 minutes;

[0052] (3) Soak peanut vines in calcium citrate-citric acid-water solution for 12 hours according to the material-to-liquid ratio of 1g:35mL to remove the astringency, and then rinse with clean water;

[0053] Described calcium citrate-citric acid-water solution contains 100mL water in every 100mL, 0.1g citric acid and 0.1g calcium citrate;

[0054](4) Spray the deastringent-treated peanut vines with rice wine (semi-dry rice wine, sugar content 15g / L) and sodium caseinate, which account for 5% of the weight of the peanut vines (after removing impurities), and sodium caseinate according to the mass ratio 6:1 composition of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com