Method for producing triethanolamine

A technology of triethanolamine and ethylene oxide, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problems of low yield of triethanolamine and high by-products, and achieve high density of active centers, Effects of inhibiting by-production of amine ethers and high exposed surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

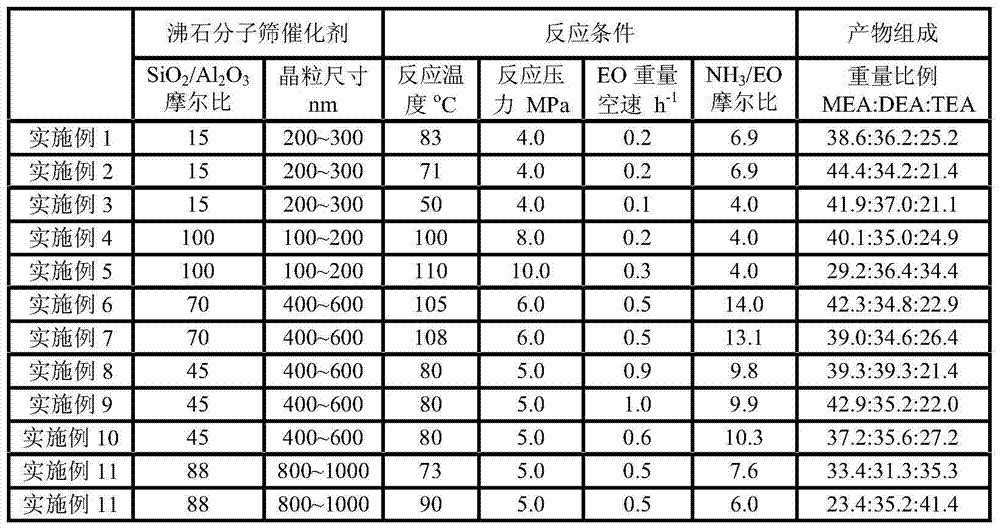

Embodiment 1

[0019] The fixed-bed reactor is filled with a binder-free hydrogen type ZSM-5 zeolite molecular sieve catalyst, the zeolite grain size is 200-300 nanometers, silicon-alumina (SiO 2 / Al 2 o 3 ) molar ratio is 15, under the condition that the reaction pressure is 4MPa and the reaction temperature is 83°C, feed anhydrous ammonia and ethylene oxide to react, wherein the ammonia / ethylene oxide molecular molar ratio is 6.9, epoxy The feed gravimetric space velocity of ethane is 0.2h -1 , the weight ratio of monoethanolamine, diethanolamine and triethanolamine in the product is 38.6:36.2:25.2.

Embodiment 2

[0021] The fixed-bed reactor is filled with a binder-free hydrogen type ZSM-5 zeolite molecular sieve catalyst, the zeolite grain size is 200-300 nanometers, silicon-alumina (SiO 2 / Al 2 o 3 ) molar ratio is 15, under the condition that the reaction pressure is 4MPa and the reaction temperature is 71°C, feed anhydrous ammonia and ethylene oxide to react, wherein the ammonia / ethylene oxide molecular molar ratio is 4.0, epoxy The feed gravimetric space velocity of ethane is 0.2h -1 , the weight ratio of monoethanolamine, diethanolamine and triethanolamine in the product is 44.4:34.2:21.4.

Embodiment 3

[0023] The fixed-bed reactor is filled with a binder-free hydrogen type ZSM-5 zeolite molecular sieve catalyst, the zeolite grain size is 200-300 nanometers, silicon-alumina (SiO 2 / Al 2 o 3 ) molar ratio is 15, under the condition that the reaction pressure is 4MPa and the reaction temperature is 50°C, feed anhydrous ammonia and ethylene oxide to react, wherein the ammonia / ethylene oxide molecular molar ratio is 6.9, epoxy The feed gravimetric space velocity of ethane is 0.1h -1 , the weight ratio of monoethanolamine, diethanolamine and triethanolamine in the product is 41.9:37.0:21.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com