The continuous production method of cyclohexanone oxime

A technology of cyclohexanone oxime and production method, which is applied in oxime preparation, organic chemistry, etc., can solve problems such as complex process route, low oxime selectivity, environmental hazards, etc., and achieve safe operation, long service life, and less sewage discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

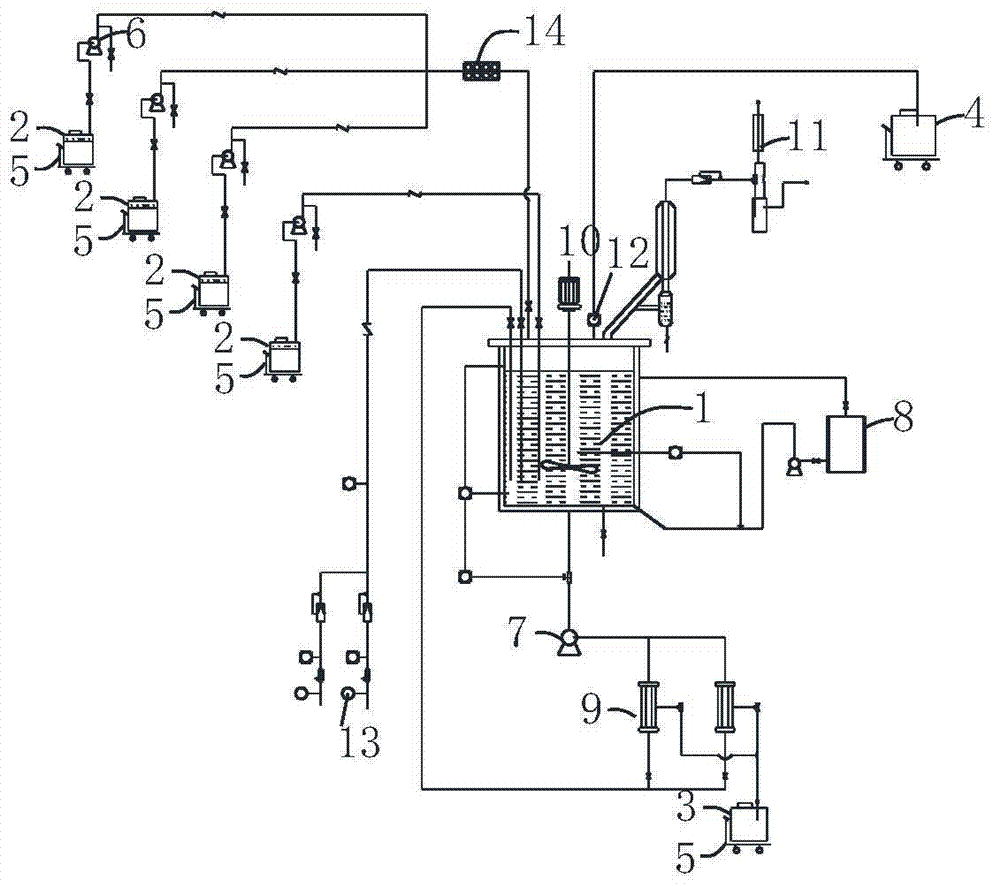

Method used

Image

Examples

Embodiment 1

[0051] In the first step, 35% concentration of hydrogen peroxide is used as the reactant, the volume of the reaction system is 3.6L, the mass fraction of the catalyst in the reaction system is 4%, and the average density of the reaction system is 866kg / m 3 , add catalyst 124.7g;

[0052] In the second step, add cyclohexanone oxime product solution and make it added to the pre-calculated scale, feed separately in proportion, cyclohexanone 8.5ml / min, tert-butanol 30.5ml / min, liquid ammonia 4.5ml / min , 35% hydrogen peroxide 7.8ml / min.

[0053] In the third step, the reaction temperature is 80° C., the reaction system pressure is 0.4 MPa, and the reaction is continued for 6 hours.

[0054] After the reaction system was stabilized, the product liquid was analyzed, and the conversion rate of cyclohexanone was 99.0%, and the selectivity of cyclohexanone oxime was 99.5%.

Embodiment 2

[0056] Implementation process is except following difference, and all the other are with embodiment 1:

[0057] In the first step, 50% concentration of hydrogen peroxide is used as a reactant, which is added to the reaction system in proportion.

[0058] The analysis results showed that the conversion rate of cyclohexanone was 99.2%, and the selectivity of cyclohexanone oxime was 99.6%.

Embodiment 3

[0060] Implementation process is except following difference, and all the other are with embodiment 1:

[0061] In the first step, 60% concentration of hydrogen peroxide is used as a reactant, which is added to the reaction system in proportion.

[0062] The analysis results showed that the conversion rate of cyclohexanone was 99.5%, and the selectivity of cyclohexanone oxime was 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com