Preparation method of molecularly imprinted material and molecularly imprinted material prepared by same

A molecularly imprinted and nanoparticle technology, applied in the preparation of molecularly imprinted materials and the field of molecularly imprinted materials, can solve the problems of inability to achieve simultaneous enrichment and detection, and achieve the effects of good chemical stability, good stability and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment includes the following steps

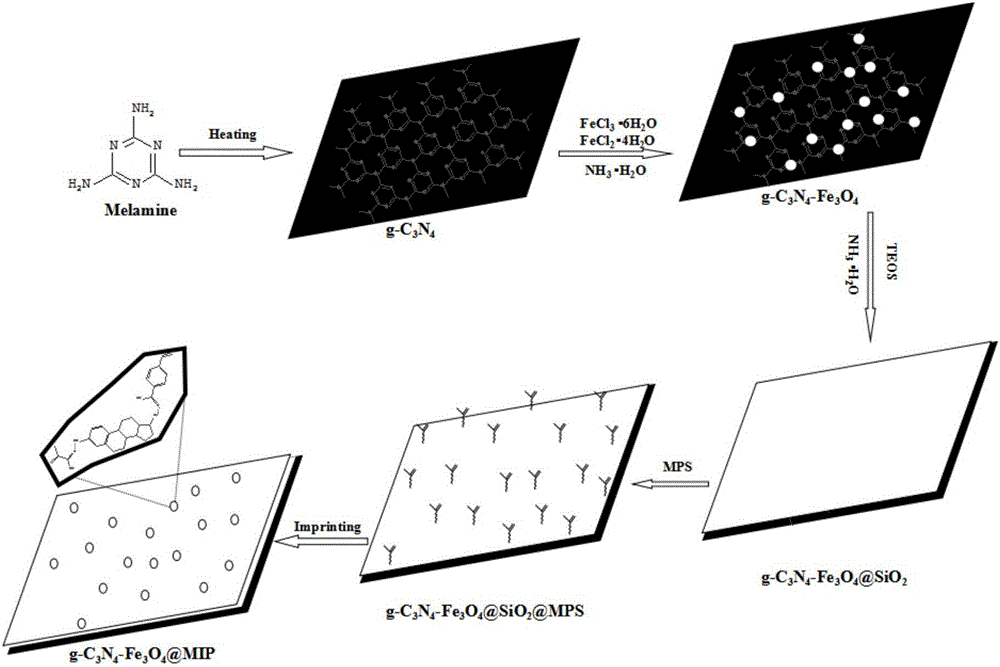

[0052] S11: g-C prepared by thermal polymerization of melamine 3 N 4 Nanoparticles

[0053] Weigh 10g of melamine and place it in a 100mL semi-closed crucible, then place the crucible in a muffle furnace and heat it to 550°C at a heating rate of 3°C / min and then keep it warm for 5h. After cooling to room temperature naturally, take it out, grind it into powder with a mortar and store it for later use.

[0054] S12: Magnetic graphite-like carbon nitride nanoparticles (g-C 3 N 4 -Fe 3 o 4 ) preparation

[0055] Weigh 125mgg-C 3 N 4 Into 500mL ethanol / water mixed solution (volume ratio 1:2), ultrasonically disperse for 5h to obtain uniformly dispersed g-C 3 N 4 suspension. 1.838gFeCl 3 ·6H 2 O (M=270) and 0.703g FeCl 2 4H 2 O (M=198) added to the above g-C 3 N 4 In the suspension, 10 mL of 28% (V / W) ammonia water was added to react for 30 min after stirring at 80° C. for 30 min. Cool to room temperature afte...

Embodiment 2

[0064] This embodiment includes the following steps

[0065] S21: g-C prepared by thermal polymerization of melamine 3 N 4 Nanoparticles

[0066] Weigh 5g of melamine into a 100mL semi-closed crucible, and then place the crucible in a muffle furnace. Heat the muffle furnace to 500°C at a heating rate of 3°C / min and keep it warm for 3h. After cooling to room temperature naturally, take it out, grind it into powder with a mortar and store it for later use.

[0067] S22: Magnetic graphite-like carbon nitride nanoparticles (g-C 3 N 4 -Fe 3 o 4 ) preparation

[0068] Weigh 100mgg-C 3 N 4 Ultrasonic dispersion with 500mL ethanol / water mixed solution (volume ratio 1:2) for 5h to obtain uniformly dispersed g-C 3 N 4 suspension. 1.62gFeCl 3 ·6H 2 O (M=270) and 0.79g FeCl 2 4H 2 O (M=198) added to the above g-C 3 N 4 In the suspension, 10 mL of 25% (V / W) ammonia water was added to react for 30 min after stirring at 80° C. for 30 min. Cool to room temperature after th...

Embodiment 3

[0077] This implementation includes the following steps

[0078] S31: g-C prepared by thermal polymerization of melamine 3 N 4 Nanoparticles

[0079] Weigh 8g of melamine and place it in a 100mL semi-closed crucible, then place the crucible in a muffle furnace. The muffle furnace was heated to 550°C at a heating rate of 3°C / min and then kept for 4h. After cooling to room temperature naturally, take it out, grind it into powder with a mortar and store it for later use.

[0080] S32: Magnetic graphite-like carbon nitride nanoparticles (g-C 3 N 4 -Fe 3 o 4 ) preparation

[0081] Weigh 150mgg-C 3 N 4 Ultrasonic dispersion with 500mL ethanol / water mixed solution (volume ratio 1:2) for 5h to obtain uniformly dispersed g-C 3 N 4 suspension. 2.430gFeCl 3 ·6H 2 O (M=270) and 0.99g FeCl 2 4H 2 O (M=198) added to the above g-C 3 N 4 In the suspension, after stirring at 80°C for 30 minutes, 10 mL of 28% (V / W) ammonia water was added to react for 60 minutes. Cool to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com