High-temperature-resistant thermally-conductive insulating material and preparation method for same

A thermally conductive insulating material and a technology for insulating materials, applied in the field of insulating materials, can solve the problems of burning insulating materials, poor thermal conductivity, and unfavorable rapid drying of clothes, and achieve good high temperature resistance, good thermal conductivity, and fill market gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

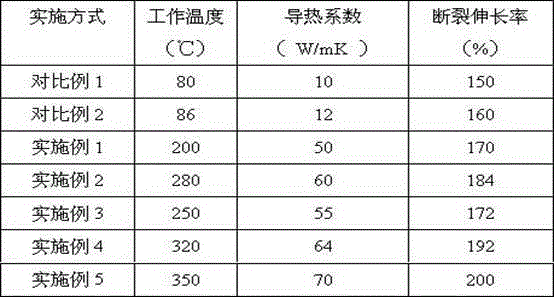

Examples

Embodiment 1

[0028] (1) Fully mix 45 parts of epoxy resin, 35 parts of ethylene-vinyl acetate copolymer and 15 parts of white carbon black in a high-speed mixer at a speed of 550r / min and set aside;

[0029] (2) Add 10 parts of 3-sulfonylamino-2-thiophene, 5 parts of mica powder and 2 parts of nano-aluminum hydroxide to step (1), raise the temperature to 80°C for 5 minutes, and then stir at a speed of 250r / min 10min, to obtain mixture A;

[0030] (3) First add 12 parts of tert-butoxycarbonyl-L-glutamic acid-5-tert-butyl ester into another reactor, raise the temperature to 120°C, then add 1.5 parts of zinc borate, microcrystalline 3 parts of wax and 7 parts of carboxymethyl cellulose silicon salt, after the completion of the heat preservation reaction for 5 minutes, the mixture B was obtained;

[0031] (4) Add the mixture B mentioned in the step (3) to the mixture A mentioned in the step (2), and input it into the twin-screw extruder after mixing thoroughly, and then knead and extrude it t...

Embodiment 2

[0033] (1) Fully mix 60 parts of epoxy resin, 55 parts of ethylene-vinyl acetate copolymer and 25 parts of white carbon black in a high-speed mixer at a speed of 650r / min and set aside;

[0034] (2) Add 18 parts of 3-sulfonylamino-2-thiophene, 12 parts of mica powder and 8 parts of nano-aluminum hydroxide to step (1), raise the temperature to 120°C for 10 minutes, and then stir at a speed of 350r / min 20min, to obtain mixture A;

[0035] (3) In another reactor, add 20 parts of tert-butoxycarbonyl-L-glutamic acid-5-tert-butyl ester first, raise the temperature to 150°C, then add 5 parts of zinc borate, microcrystalline 7 parts of wax and 15 parts of carboxymethyl cellulose silicon salt, after completion of the heat preservation reaction for 15 minutes, mixture B was obtained;

[0036] (4) Add the mixture B mentioned in the step (3) to the mixture A mentioned in the step (2), and input it into the twin-screw extruder after mixing thoroughly, and then knead and extrude it through...

Embodiment 3

[0038] (1) Fully mix 50 parts of epoxy resin, 40 parts of ethylene-vinyl acetate copolymer and 18 parts of white carbon black in a high-speed mixer at a speed of 600r / min for use;

[0039] (2) Add 12 parts of 3-sulfonylamino-2-thiophene, 8 parts of mica powder and 3 parts of nano-aluminum hydroxide to step (1), raise the temperature to 100°C for 7 minutes, and then stir at a speed of 250r / min 13min, mixture A was obtained;

[0040] (3) In another reactor, add 14 parts of tert-butoxycarbonyl-L-glutamic acid-5-tert-butyl ester, raise the temperature to 135°C, then add 2.5 parts of zinc borate, microcrystalline 4 parts of wax and 9 parts of carboxymethyl cellulose silicon salt, after the completion of heat preservation reaction for 10 minutes, mixture B was obtained;

[0041] (4) Add the mixture B mentioned in the step (3) to the mixture A mentioned in the step (2), and input it into the twin-screw extruder after mixing thoroughly, and then knead and extrude it through the twin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com