Oil, aviation bio-fuel component and preparation method of aviation bio-fuel component by using Aleurites montana seeds

A biofuel and aviation technology, which is applied in the preparation of biological raw materials, liquid hydrocarbon mixtures, fat oil/fat production, etc., can solve the problems of low oil quality, poor thermal stability, and low combustion calorific value, and achieve good stability, Ease of operation and high calorific value of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

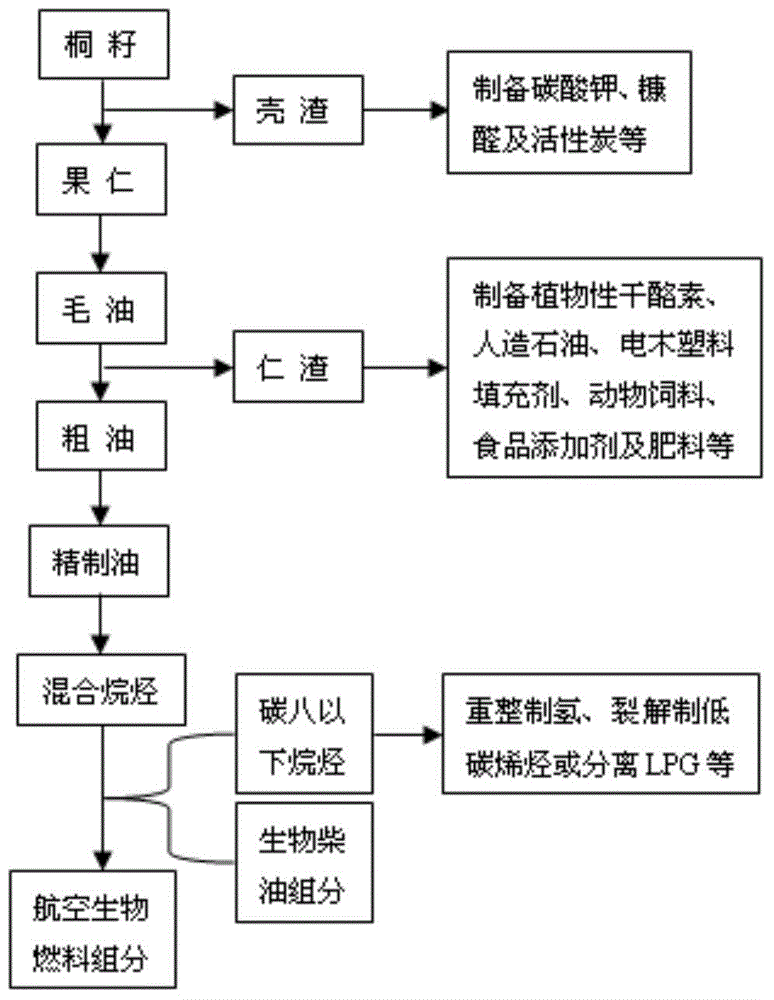

Embodiment 1

[0025] Use a buckwheat sheller to peel off the husk of the thousand-year-old tung seed to obtain the nuts. The content of the nuts in the shell residue is 0.6wt%, and the content of the shell residue in the nuts reaches 0.3wt%. A large amount of shell residue produced during the shelling process can be used for Preparation of chemical raw materials such as potassium carbonate, furfural and activated carbon. Put the nuts into the screw oil press and squeeze them into crude oil. The crude oil is squeezed and filtered through a filter to obtain rough millennium tung seed oil. The filtered kernel residue contains almost no oil. After further processing, the kernel residue can be made into vegetable oil. Casein, artificial petroleum, fillers for Bakelite plastics, animal feed, food additives and soil fertilizers.

[0026] Demetallize the crude millennium tung tree oil with sodium aluminosilicate, deacidify with steam, degumming with citric acid, decolorize with clay, and dechlorina...

Embodiment 2

[0029] Use the barley shelling machine to peel off the shell of the thousand-year-old tung seed to obtain the nuts. The content of the nuts in the shell residue is 0.2wt%, and the content of the shell residue in the nuts reaches 0.3wt%. A large amount of shell residues produced during the shelling process can be used for Preparation of chemical raw materials such as potassium carbonate, furfural and activated carbon. Put the nuts into a hydraulic oil press and squeeze them into crude oil. The crude oil is squeezed and filtered through a filter to obtain rough millennium tung seed oil. The filtered kernel residue contains almost no oil. After further processing, the kernel residue can be made into vegetable oil. Casein, artificial petroleum, fillers for Bakelite plastics, animal feed, food additives and soil fertilizers.

[0030] Demetallize the crude millennium tung seed oil with macroporous silica gel, deacidify with hot water, degumming with phosphoric acid, decolorize with ...

Embodiment 3

[0033] Use the peanut sheller to peel off the shell of the thousand-year-old tung seed to obtain the nuts. The content of the nuts in the shell residue is 0.4wt%, and the content of the shell residue in the nuts reaches 0.5wt%. A large amount of shell residues produced during the shelling process can be used for Preparation of chemical raw materials such as potassium carbonate, furfural and activated carbon. Put the nuts into the screw oil press and squeeze them into crude oil. The crude oil is squeezed and filtered through a filter to obtain rough millennium tung seed oil. The filtered kernel residue contains almost no oil. After further processing, the kernel residue can be made into vegetable oil. Casein, artificial petroleum, fillers for Bakelite plastics, animal feed, food additives and soil fertilizers.

[0034] Demetallize the crude millennium tung seed oil with chabazite, deacidify with steam, degumming with rice husk, decolorize with diatomaceous earth, and dechlorina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com