Method for producing raw oil of biodiesel

A technology for biodiesel and a production method, which is applied in the fields of biotechnology and renewable energy, can solve the problems of low output, complex process, long cycle of biodiesel feedstock oil, etc., and achieves the effects of low production cost, high efficiency, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

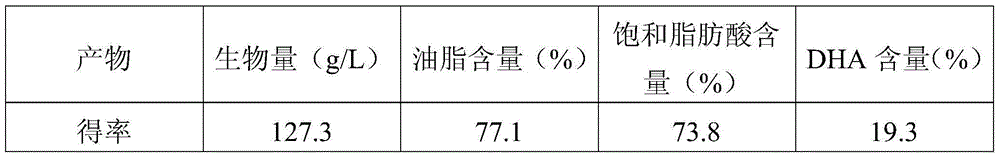

Embodiment 1

[0029] The production method of biodiesel raw material oil, comprises the following steps:

[0030] (1) prepare seed culture medium, sterilize for later use

[0031] Seed medium includes: glucose 40.0g / L, yeast powder 5.0g / L, peptone 1.0g / L, magnesium sulfate 0.5g / L, calcium bicarbonate 0.2g / L, potassium dihydrogen phosphate 1.0g / L, chloride Sodium 1.0g / L.

[0032] (2) Preparation of fermentation medium, sterilized for subsequent use

[0033] Fermentation medium includes: glucose 80.0g / L, corn steep liquor 10.0g / L, sodium glutamate 8.0g / L, magnesium sulfate 0.5g / L, calcium bicarbonate 1.0g / L, potassium dihydrogen phosphate 1.0g / L , sodium nitrate 5.0g / L.

[0034] (3) Preparation of seed solution

[0035] Inoculate Schizochytrium into the seed culture medium, the inoculum volume percentage is 2%, shake flask culture is carried out under the conditions of shaking table rotation speed 300rpm, culture temperature 28 ℃ for 24h, to obtain seed liquid.

[0036] (4) Fermentation ...

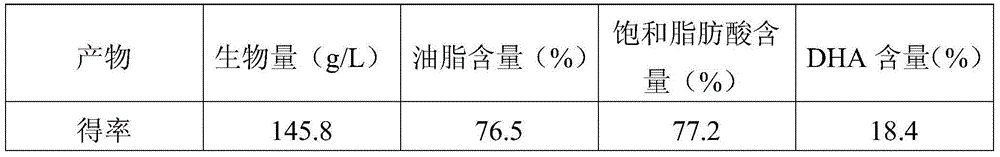

Embodiment 2

[0043] The production method of biodiesel raw material oil, comprises the following steps:

[0044] (1) prepare seed culture medium, sterilize for later use

[0045] Seed medium includes: glucose 60.0g / L, yeast powder 10.0g / L, peptone 5.0g / L, magnesium sulfate 2.0g / L, calcium bicarbonate 1.0g / L, potassium dihydrogen phosphate 3.0g / L, chloride Sodium 5.0g / L.

[0046] (2) Preparation of fermentation medium, sterilized for subsequent use

[0047] Fermentation medium includes: glucose 150.0g / L, corn steep liquor 30.0g / L, sodium glutamate 20.0g / L, magnesium sulfate 3.0g / L, calcium bicarbonate 5.0g / L, potassium dihydrogen phosphate 3.0g / L , sodium nitrate 10.0g / L.

[0048] (3) Preparation of seed solution

[0049] Inoculate Schizochytrium into the seed culture medium with an inoculum volume percentage of 5%, shake flask culture for 20 h under the conditions of a shaker rotation speed of 180 rpm and a culture temperature of 40° C. to obtain a seed solution.

[0050] (4) Fermenta...

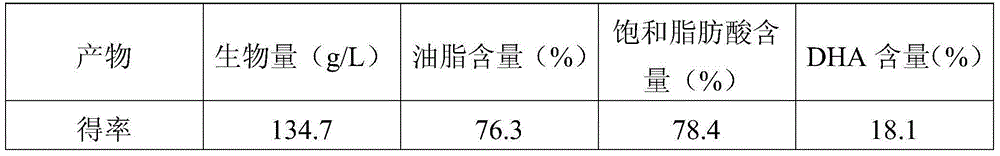

Embodiment 3

[0057] The production method of biodiesel raw material oil, comprises the following steps:

[0058] (1) prepare seed culture medium, sterilize for later use

[0059] Seed medium includes: glucose 45.0g / L, yeast powder 6.0g / L, peptone 2.0g / L, magnesium sulfate 1.0g / L, calcium bicarbonate 0.4g / L, potassium dihydrogen phosphate 1.5g / L, chloride Sodium 2.0g / L.

[0060] (2) Preparation of fermentation medium, sterilized for subsequent use

[0061] Fermentation medium includes: glucose 100.0g / L, corn steep liquor 15.0g / L, sodium glutamate 10.0g / L, magnesium sulfate 1.0g / L, calcium bicarbonate 2.0g / L, potassium dihydrogen phosphate 1.5g / L , sodium nitrate 6.0g / L.

[0062] (3) Preparation of seed solution

[0063] Inoculate Schizochytrium into the seed culture medium with an inoculum volume percentage of 3%, shake flask culture for 22 hours under the conditions of a shaker rotation speed of 200 rpm and a culture temperature of 32° C. to obtain a seed solution.

[0064] (4) Fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com