Method for preparing medium- and long-chain triglyceride by virtue of packed bed reactor

A packed bed reactor, triglyceride technology, applied in chemical instruments and methods, biochemical equipment and methods, enzymes, etc., can solve the problem of repeated recycling of unfavorable enzyme activities, unmentioned recycling of enzyme particles and by-products, reaction Long time and other problems, to achieve the effect of shortening the reaction time, reducing the reaction cost and improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

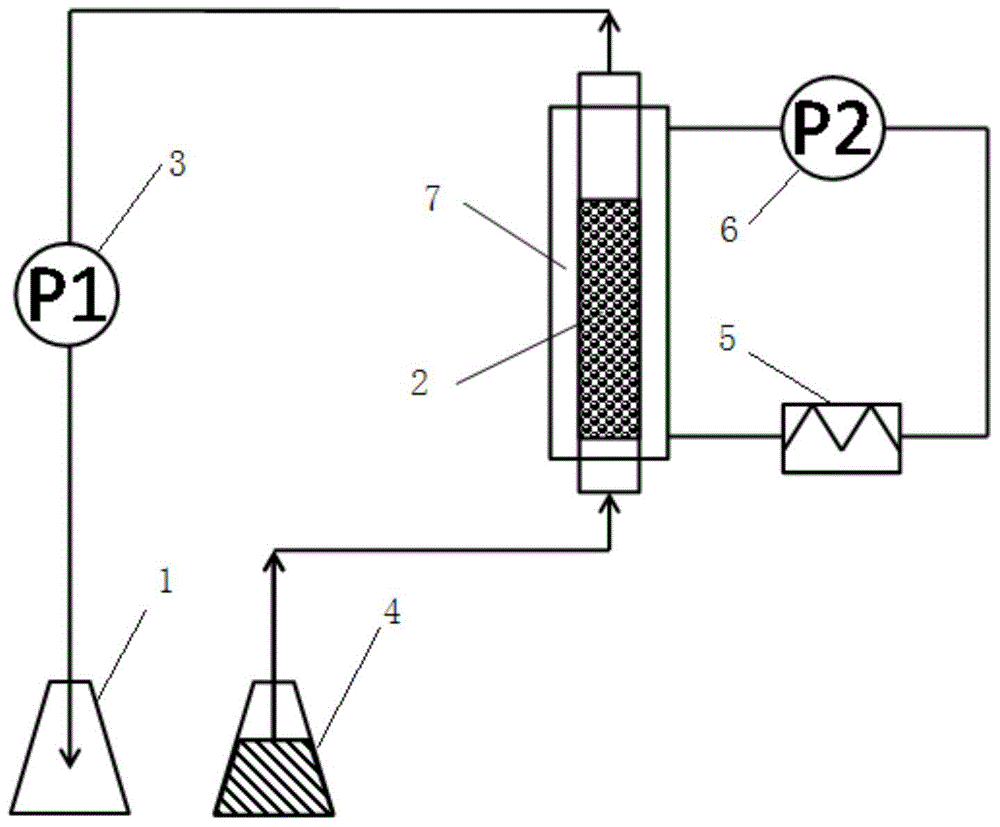

[0033] A method for preparing medium and long-chain triglycerides using a packed bed reactor, the method is as Figure 4 shown, including the following steps:

[0034] (1) A certain amount of Novozymes immobilized lipase LipozymeTLIM is filled in a glass reaction column with a heat jacket 7 to make an enzyme packed bed reactor; the schematic diagram of the enzyme packed bed reactor device is as follows image 3 As shown, it includes product tank 1, packed column 2, constant flow pump 3, substrate tank 4, constant temperature thermal bath 5 and thermal bath pump 6, wherein product tank 1, packed column 2, constant current pump 3 and substrate tank 4 Connected sequentially, the constant-temperature thermal bath 5, the thermal bath pump 6 and the thermal jacket 7 are circularly connected.

[0035] (2) Get the mixture of 45.0g caprylic acid glyceride and 55.0g soybean oil as reaction substrate, add in the substrate tank 4.

[0036] (3) Turn on the constant temperature heat bath ...

Embodiment 2

[0047] This implementation example is the same as Example 1 except the following technical characteristics: the reactant used in the step (2) is the mixture of 40.0g caprylic acid glyceride and 60.0g soybean oil; the reaction temperature described in the step (3) is 80 ℃ , the flow rate is 1.4mL / min, and the reaction time is 60min; in step (4), the ethanol with a mass concentration of 85% is used to extract the crude product obtained after the transesterification reaction, and the solid-liquid ratio of the crude product and ethanol is 1:9, After vacuum distillation, the final product is obtained.

[0048] Through the detection and calculation of the method described in Example 1, the content of medium and long-chain triglycerides in the crude product obtained after step (3) transesterification in this example is 68.8%; the final product is obtained after extraction and vacuum distillation, The yield was 82.1%, and the medium and long-chain triglyceride content in the final pro...

Embodiment 3

[0050] This embodiment example is with embodiment 1 except following technical characteristics: used reactant is the mixture of 45.0g caprylic acid glyceride and 55.0g soybean oil in the step (2); The temperature of reaction described in the step (3) is 70 ℃ , the flow rate is 1mL / min, and the reaction time is 30min; in step (4), adopting mass concentration as 75% ethanol solution to extract the crude product obtained after transesterification, the solid-liquid ratio of crude product and ethanol solution is 1:9 , and then obtain the final product after vacuum distillation.

[0051] Through the detection and calculation of the method described in Example 1, the content of medium and long-chain triglycerides in the crude product obtained after step (3) transesterification in this example is 67.0%; the final product is obtained after extraction and vacuum distillation, The yield was 80.4%, and the medium and long-chain triglyceride content in the final product was 75.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com