Preparation method of bionic oil-water separation copper net

A technology of bionic oil and copper mesh, which is applied in the field of preparing bionic oil-water separation copper mesh by electrochemical deposition method, can solve the problems of complicated processing steps, easy to be polluted, high operating costs, etc., and achieve good mechanical stability and reusable properties, The effect of controllable experimental parameters and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

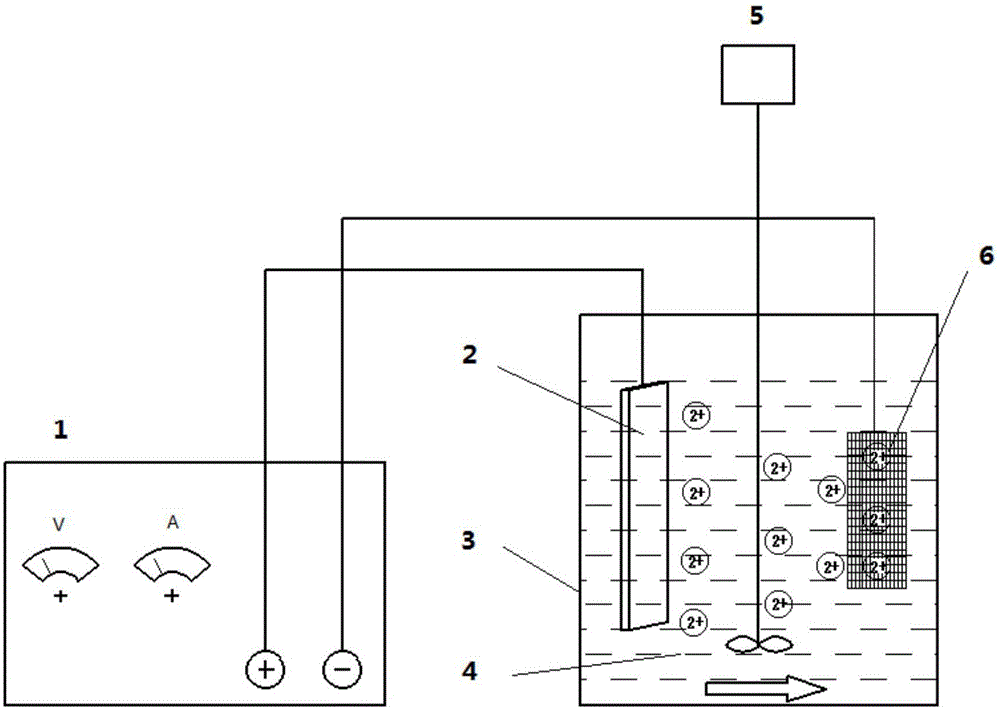

[0031] A preparation method of a bionic oil-water separation copper mesh, the specific steps are as follows:

[0032] A. Pretreatment of the copper mesh: Place the copper mesh in dilute hydrochloric acid, acetone and distilled water for 10 minutes of ultrasonic cleaning to remove the oxide film and dirt on the surface;

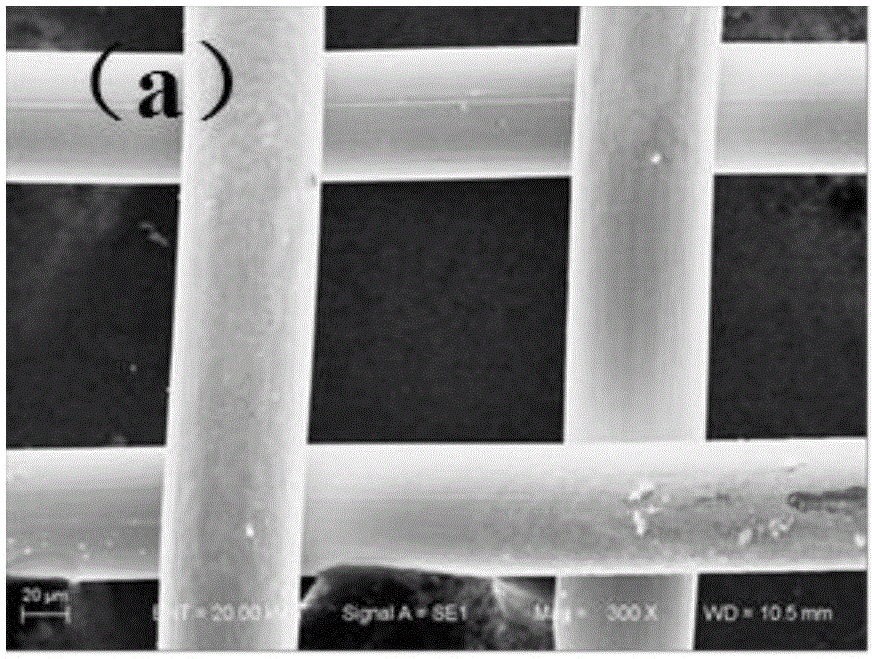

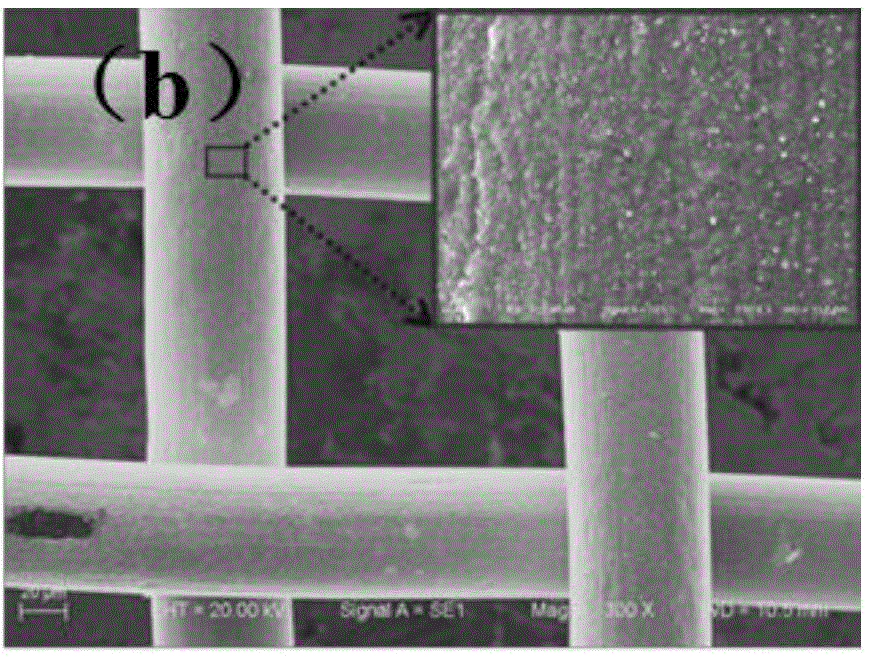

[0033] B. Electrochemical deposition: The copper grid after cleaning is immersed in the electroplating solution for electrolysis. The electroplating solution is composed of 0.12mol / L copper sulfate and 0.1mol / L sulfuric acid. The volume of the electroplating solution is 150ml. The anode and the copper mesh are used as the cathode to electroplate the copper mesh. The voltage is 3.5V and the electroplating time is 100s. Double-layer hierarchical structure surface;

[0034] C. Surface modification: After the electroplating is completed, soak the copper mesh with bionic micro-nano double-layer hierarchical structure to contain 1.5×10 -3 mol / L ethanol solution of...

Embodiment 2

[0036] A preparation method of a bionic oil-water separation copper mesh, the specific steps are as follows:

[0037] A. Pretreatment of the copper mesh: Place the copper mesh in dilute hydrochloric acid, acetone and distilled water for 10 minutes of ultrasonic cleaning to remove the oxide film and dirt on the surface;

[0038] B. Electrochemical deposition: The copper net after cleaning is immersed in the electroplating solution for electrolysis. The electroplating solution is composed of 0.12mol / L copper sulfate and 0.2mol / L sulfuric acid. The volume of the electroplating solution is 180ml. The anode and the copper mesh are used as the cathode to electroplate the copper mesh. The voltage is 3.5V and the electroplating time is 150s. layer hierarchy surface;

[0039] C. Surface modification: After the electroplating is completed, soak the copper mesh with bionic micro-nano double-layer hierarchical structure to contain 1.5×10 -3 mol / L ethanol solution of lauric acid, take it...

Embodiment 3

[0041] A preparation method of a bionic oil-water separation copper mesh, the specific steps are as follows:

[0042] A. Pretreatment of the copper mesh: Place the copper mesh in dilute hydrochloric acid, acetone and distilled water for 10 minutes of ultrasonic cleaning to remove the oxide film and dirt on the surface;

[0043]B. Electrochemical deposition: The copper grid after cleaning is immersed in the electroplating solution for electrolysis. The electroplating solution is composed of 0.15mol / L copper sulfate and 0.2mol / L sulfuric acid. The volume of the electroplating solution is 200ml; The anode and the copper mesh are used as the cathode to electroplate the copper mesh, the voltage is 4.0V, and the electroplating time is 250s. After the reaction is completed, a microstructure is formed on the surface of the copper mesh as a bionic papillae, that is, a bionic micro-nano scale double-layer is formed on the copper substrate. layer hierarchy surface;

[0044] C. Surface m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com