Ultraviolet curable composition for cyclic olefin resin and cyclic olefin resin film using the same

A technology of cyclic olefin resin and curable composition, which is applied in the direction of coating, etc., can solve the problems of lower yield, higher cost, yellow coloring of cured coating film, etc., and achieve the effect of less coloring and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The present invention will be described more specifically by way of examples below.

Synthetic example 1

[0061] (Synthesis Example 1: Synthesis of Urethane Acrylate (A2-1))

[0062] Put 254 parts by mass of butyl acetate, 222 parts by mass of isophorone diisocyanate, 0.5 parts by mass of p-methoxyphenol and 0.5 parts by mass of dibutyltin diacetate into a flask equipped with a stirrer, a gas inlet tube, a condenser tube and a thermometer Parts, while blowing air, while raising the temperature to 70 ° C, and then dropwise added a mixture of pentaerythritol triacrylate (hereinafter abbreviated as "PE3A") and pentaerythritol tetraacrylate (hereinafter abbreviated as "PE4A") (PE3A / PE4A=75 / 25 (mass ratio)) 400 parts by mass and 497 parts by mass of isocyanuric acid oxirane-modified diacrylate. After the dropwise addition, react at 70° C. for 3 hours, and then allow the reaction to proceed to 2250 cm of the isocyanate group. -1 The solution containing the urethane acrylate (A2-1) which has 6 acryloyl groups in 1 molecule until the infrared absorption spectrum disappears, and the non-...

Embodiment 1

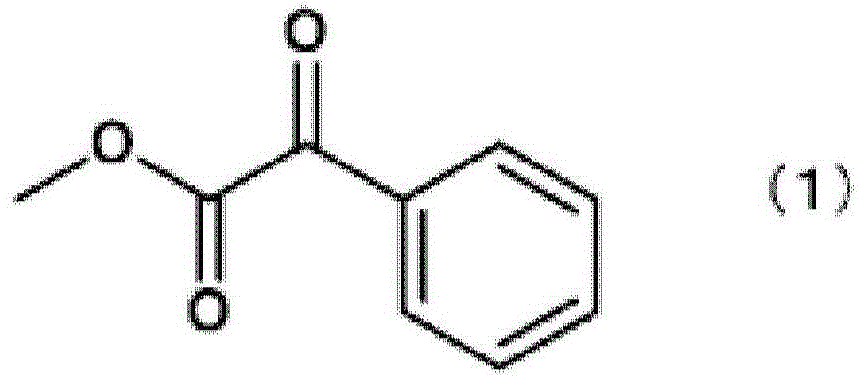

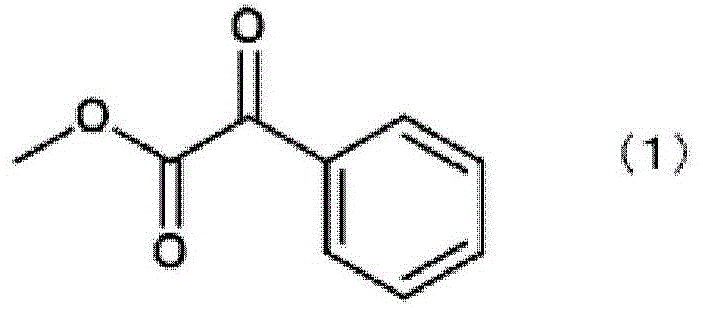

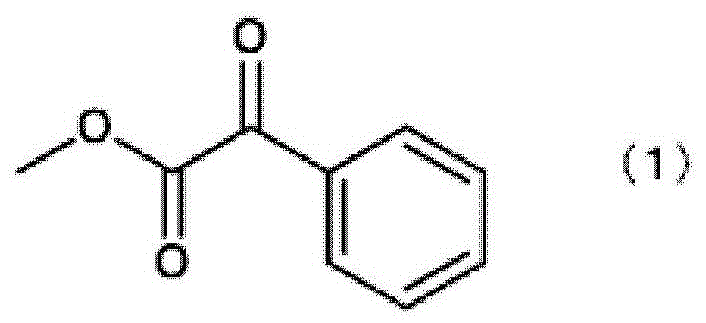

[0064] 35 parts by mass of a mixture (DPHA / DPPA=65 / 35 (mass ratio)) of dipentaerythritol hexaacrylate (hereinafter abbreviated as "DPHA") and dipentaerythritol pentaacrylate (hereinafter abbreviated as "DPPA"), poly 30% by mass methyl ethyl ketone dispersion of 65 parts by mass of ester acrylate (tetrafunctional, molecular weight 1,800), silica microparticles ("MEK-ST" manufactured by Nissan Chemical Industries, Ltd., average particle diameter 10 to 20 nm, organosilica sol) ; Hereinafter abbreviated as "silica microparticle dispersion (1)".) 25 parts by mass (7.5 parts by mass based on silica microparticles), and 2-(2-oxo-2-phenyl Acetoxyethoxy) ethyl ester (hereinafter abbreviated as "photopolymerization initiator (B1-1)") 3 parts by mass was stirred evenly, and then diluted with methyl ethyl ketone to prepare an ultraviolet curable composition with a non-volatile content of 25 mass%. thing (1).

[0065] [Preparation of film for evaluation]

[0066] Using a wire bar, the ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com