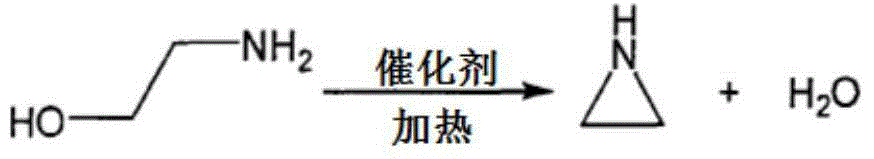

Acid-activated montmorillonite cesium-loaded catalyst and application thereof in catalytic synthesis of aziridine from monoethanolamine

A technology of montmorillonite and acid activation, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problem of affecting the selectivity of aziridine products and the conversion of high monoethanolamine efficiency, aziridine selectivity reduction and other issues, to achieve the effect of improving the diffusion effect, increasing the selectivity, and increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of acid-activated montmorillonite

[0027] Disperse 16.33g montmorillonite in 800g mass fraction of 20% nitric acid aqueous solution, prepare a mass fraction of 2% montmorillonite suspension, stir, activate at 104°C for 24 hours, centrifuge at 8000 rpm for 6 Minutes, the precipitate was washed with distilled water until neutral, dried in an oven at 80°C for 12 hours, then baked in a muffle furnace at 900°C for 4 hours, cooled naturally to room temperature, and ground with a mortar to prepare acid-activated montmorillonite .

[0028] 2. Preparation of acid-activated montmorillonite-supported cesium catalyst

[0029] Using equal volume impregnation method, according to Cs 1 P 0.8 o 7 The stoichiometric ratio, 0.26g cesium nitrate, 0.22g ammonium phosphate trihydrate were added to deionized water, and left to stand for 15 minutes to obtain the impregnation solution; according to Cs 1 P 0.8 o 7 The loading capacity is 18%. Add 2.0g acid-activated montm...

Embodiment 2

[0031] In steps 1 and 2 of Example 1, the calcination temperature was changed to 850°C, and the other steps were the same as in Example 1 to prepare an acid-activated montmorillonite-loaded cesium catalyst with a specific surface area of 15.96m 2 / g, the pore volume is 0.042cm 3 / g, the average pore diameter is 23.23nm.

Embodiment 3

[0033] In steps 1 and 2 of Example 1, the calcination temperature was changed to 800°C, and the other steps were the same as in Example 1 to prepare an acid-activated montmorillonite-loaded cesium catalyst with a specific surface area of 20.78m 2 / g, the pore volume is 0.052cm 3 / g, the average pore diameter is 19.80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com