A kind of slow-release fertilizer and preparation method thereof

A technology of slow-release fertilizers and coating materials, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as pollution, not easy to degrade, and soil degradation, and achieve high economic benefits and uniform and stable release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

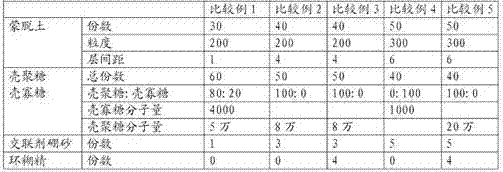

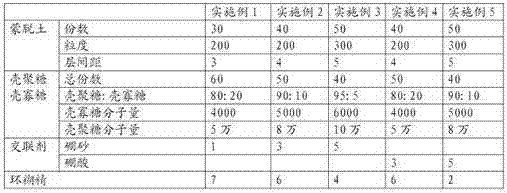

Embodiment 1

[0052] Dissolve cyclodextrin, chitosan and chitosan oligosaccharide with 5% acetic acid to make chitosan acetic acid solution, stir at 1500rpm for 15 minutes, add the acid solution to the mixed solution of 5%HAc / montmorillonite In, continue to stir for 3 hours, prepare the solution of coating material;

[0053] (2) Put the fertilizer granules to be coated into a coating machine, spray the solution of the coating material under the rotation of the coating machine, mix evenly, heat up, and dry to obtain dry granules;

[0054] (3) Then add the dried granules to an aqueous solution of 0.1% borax crosslinking agent, soak for 30 minutes, filter, and dry the resulting solid to obtain slow-release fertilizer granules.

[0055] Wherein in the drying step, drying to a water content less than or equal to 4.0%.

[0056] The fertilizer used in Example 1 is urea. After the coating is completed, the film material is 7.5% of the weight of the fertilizer, and the N content of the fertilizer i...

Embodiment 2

[0058] Dissolve cyclodextrin, chitosan and oligochitosan with 5% phosphoric acid to make a phosphoric acid solution, stir at 1500rpm for 20 minutes, add the acid solution to the mixed solution of 5% phosphoric acid / montmorillonite, continue Stirring for 3 hours to prepare a solution of the coating material;

[0059] Put the fertilizer granules to be coated into the coating machine, spray the coating material solution under the rotation of the coating machine, mix evenly, heat up, and dry to obtain dry granules;

[0060] Then the dry granules are added into an aqueous solution of borax crosslinking agent with a mass concentration of 10%, soaked for 10 minutes, filtered, and the obtained solid is dried to obtain slow-release fertilizer granules.

[0061] Wherein in the drying step, drying to a water content less than or equal to 4.0%.

[0062] The fertilizer used in Example 1 is urea. After the coating is completed, the film material is 8.2% of the weight of the fertilizer, and...

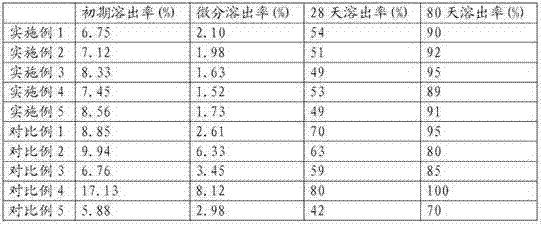

experiment example

[0070] Measure the dissolution test of the above samples at 25°C according to the national standard (GB / T 23348-200) of "Slow Release Fertilizer" formulated by my country in 2009: Weigh 10g of fertilizer and put it into a double-layer pouch made of 100-mesh nylon gauze , seal, put the pouch into a plastic bottle containing 250ml of distilled water, cover and seal it, incubate at a constant temperature of 25°C, take samples at regular intervals, transfer the water sample to another small bottle for each sampling, shake well and measure the sample. Add 250ml of distilled water again in the vial that nylon cloth is housed again, put into constant temperature Puyang county after affixing a seal, continue to cultivate, every kind of fertilizer carries out 3 parallel tests. According to the test results, calculate and measure the initial dissolution rate of the fertilizer dissolved in the fertilizer core within 24 hours, and the cumulative dissolution rate at 28, 60 and 90 days.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com