A kind of normal temperature sulfur solvent and preparation method thereof

A technology of sulfur solvent and normal temperature, applied in chemical instruments and methods, earthwork drilling, mechanical equipment, etc., can solve the problems of DMDS expensive, slow sulfur dissolving speed, explosive, etc., to overcome the slow sulfur dissolving speed, sulfur dissolving Increased speed and high sulfur solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

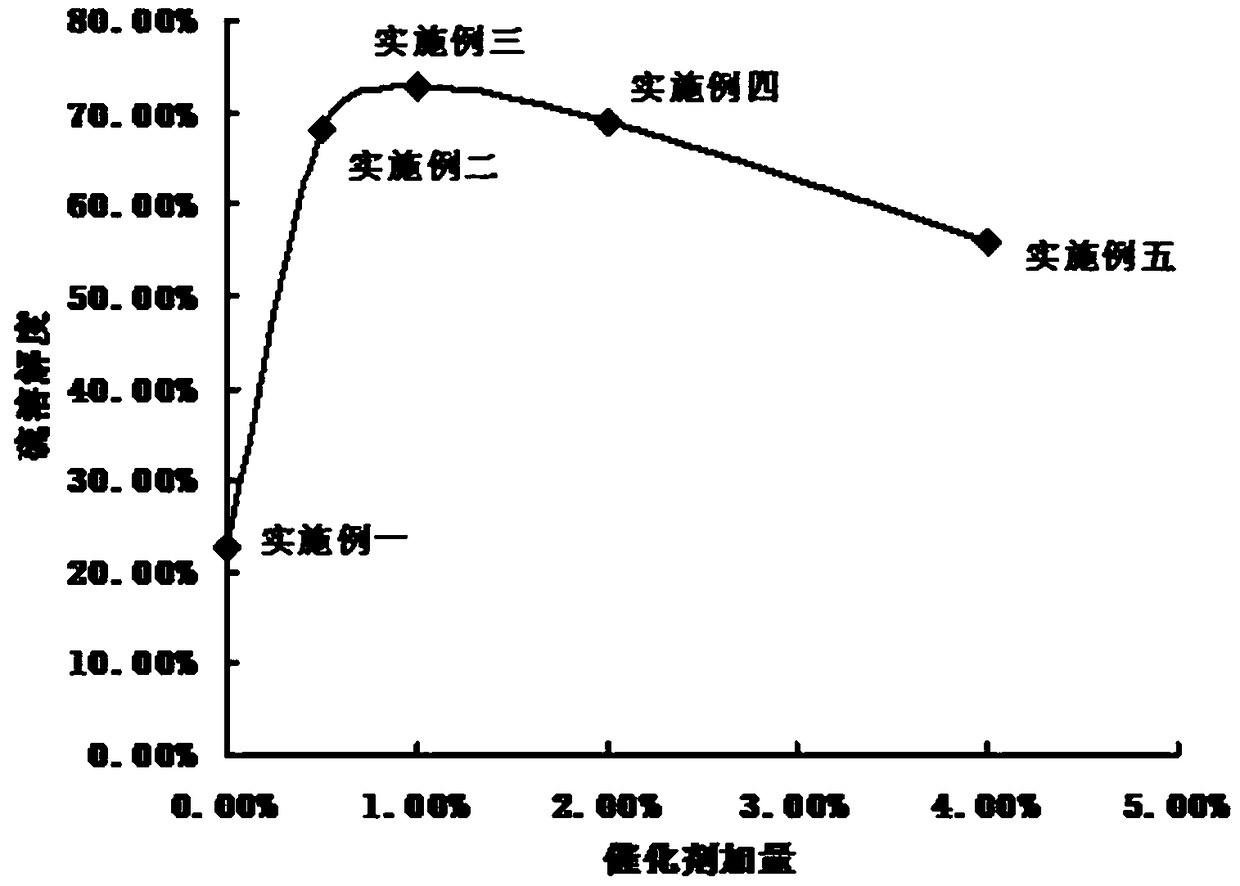

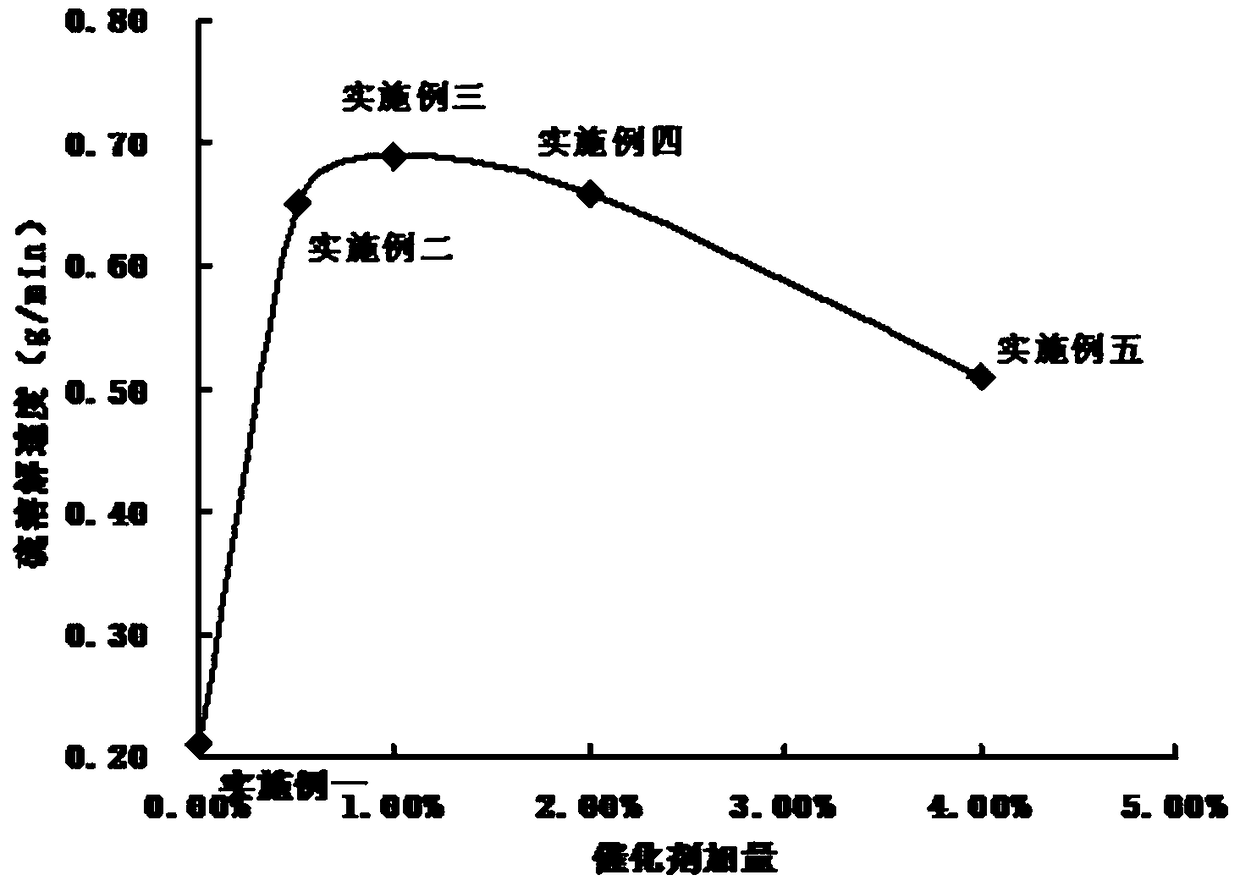

[0032] Take 50 parts of the main solvent at room temperature (about 25°C) and add it to the reaction vessel, then add 0 parts of the catalyst, stir evenly, then add 0 parts of the co-catalyst, continue to stir, and stir evenly to obtain a sulfur solvent, add sublimated sulfur to dissolve Sublimation sulfur powder experiment, and record the dissolution time, test the sulfur dissolution rate of sulfur solvent, the results are as attached figure 1 , 2 .

[0033] Experimental method and steps:

[0034] The experiment was carried out under atmospheric pressure and a certain temperature. Sublimed sulfur (chemically pure) powder with a mass of M0 was added to a sulfur solvent with a mass of M, and the magnetic stirrer rotated at 250r / min. After fully dissolving, the mixed solution of sulfur and sulfur solvent Pour it into a filter paper funnel with a mass of M1 for suction filtration, and rinse the filter paper with tetrahydrofuran at a corresponding temperature, then dry the liqui...

Embodiment 2

[0036] Take 50 parts of the main solvent at room temperature (about 25°C) and add it to the reaction vessel, then add 0.25 parts of the catalyst, stir evenly, then add 0 part of the co-catalyst, continue to stir, and stir evenly to obtain a sulfur solvent, add sublimated sulfur to dissolve Sublimation sulfur powder experiment, and record the dissolution time, test the sulfur dissolution rate of sulfur solvent, the results are as attached figure 1 , 2 .

[0037] The experimental method and steps are the same as in Example 1.

Embodiment 3

[0039] Take 50 parts of the main solvent at room temperature (about 25°C) and add it to the reaction vessel, then add 0.5 parts of the catalyst, stir evenly, then add 0 part of the co-catalyst, continue to stir, and stir evenly to obtain a sulfur solvent, add sublimated sulfur to dissolve Sublimation sulfur powder experiment, and record the dissolution time, test the sulfur dissolution rate of sulfur solvent, the results are as attached figure 1 , 2 .

[0040] The experimental method and steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com