Preparation method of drug for hyperphosphatemia

A technology for hyperphosphatemia and drugs, which is applied in drug combinations, pharmaceutical formulations, and medical preparations with inactive ingredients, etc., can solve the problems of low tablet hardness, prone to pockmarking, and soft crystal structure, etc. The effect of smooth drug filling, improved production controllability, and improved hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

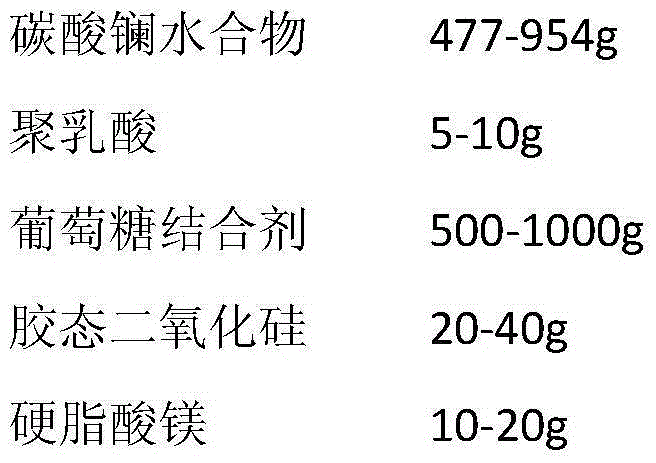

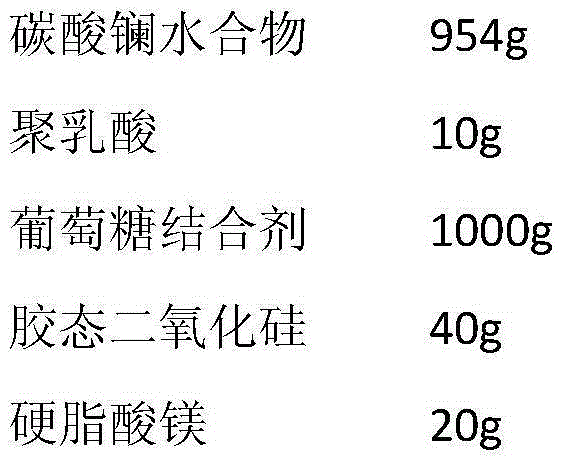

[0024] a. Weigh the following raw materials in proportion:

[0025]

[0026] Wherein the lanthanum carbonate hydrate has a water content approximately equal to 4 to 5 moles of water.

[0027] b. Mix 954g lanthanum carbonate hydrate with 10g polylactic acid, 1000g glucose binder, 40g colloidal silicon dioxide, put into dry granulation machine to make granules, the extrusion pressure is 4MPa, and the drug tablet bulk density is 0.8g / ml; crushed into granules by vibration, select 30% of the particle size below 60 mesh; 70% of the sieve above 60 mesh;

[0028] c. Mix the drug granules and 20g of magnesium stearate evenly, and press into tablets to obtain lanthanum carbonate chewable tablets.

Embodiment 2

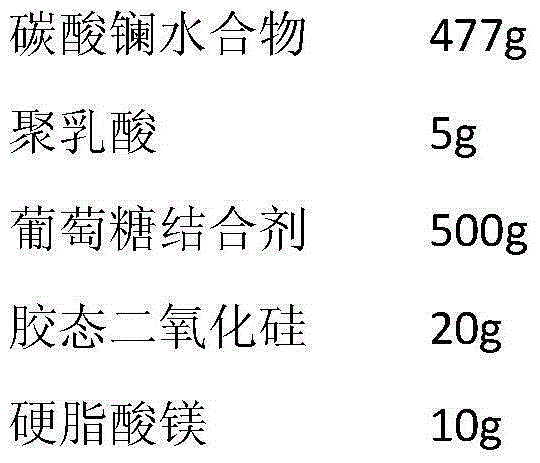

[0030] a. Weigh the following raw materials in proportion:

[0031]

[0032] Where the lanthanum carbonate is hydrated, it has a water content approximately equal to 4 to 5 moles of water.

[0033] b. Mix 477g of lanthanum carbonate with 5g of polylactic acid, 500g of glucose, and 20g of colloidal silicon dioxide, and put them into a dry granulator to obtain granules. The extrusion pressure is 4MPa, and the drug tablet bulk density is 0.8g / ml; after shaking Broken into granules, select 30% of the particle size below 60 mesh; screen and intercept 70% of the particle size above 60 mesh;

[0034] c. Mix the drug granules and 10g of magnesium stearate evenly, and press into tablets to obtain lanthanum carbonate chewable tablets.

Embodiment 3

[0036] a. Weigh the following raw materials in proportion:

[0037]

[0038] Wherein the lanthanum carbonate hydrate has a water content approximately equal to 4 to 5 moles of water.

[0039] b. Mix 954g of lanthanum carbonate hydrate with 1000g of dextrose binder and 40g of colloidal silicon dioxide, and put it into a dry granulator to obtain granules. The extrusion pressure is 4MPa, and the bulk density of the drug tablet is 0.8g / ml; Broken into granules, select 30% of the particle size below 60 mesh; screen and intercept 70% of the particle size above 60 mesh;

[0040] c. Mix the drug granules and 20g of magnesium stearate evenly, and press into tablets to obtain lanthanum carbonate chewable tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com