Polymer coating microneedle patch convenient for antibiotic skin testing and preparation method thereof

A technology of polymer coating and microneedle sticking, which is applied in the fields of drug devices, ovulation diagnosis, and other medical devices. It can solve problems such as difficulty in popularization, high sensitivity, and undetectable allergic reactions, and achieve convenient drug delivery. , the effect of rapid skin test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

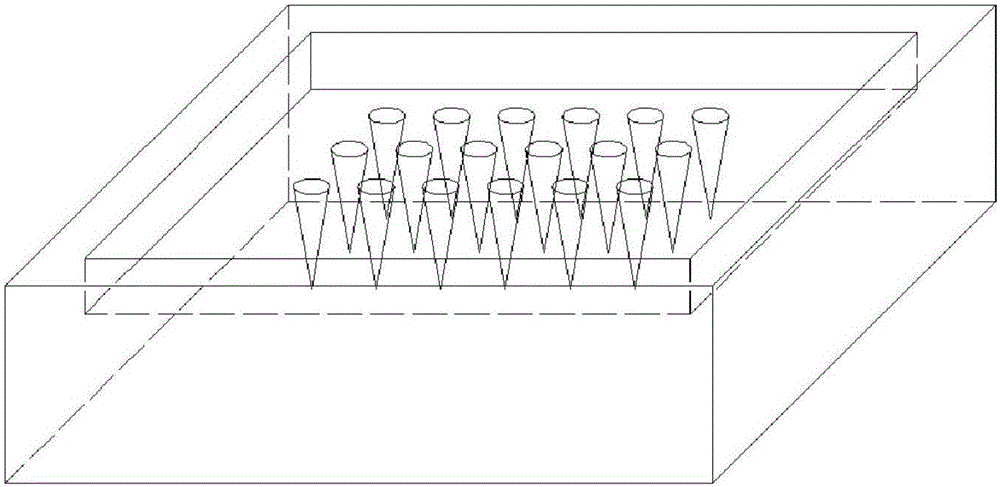

[0017] 1. Mix the polydimethylsiloxane and the curing agent according to the mass ratio of 10:1, stir well and remove the bubbles in it by vacuuming; then put the liquid polydimethylsiloxane containing the curing agent to Pour it into a container placed horizontally, place it in an oven at 60° C. and heat it for 5-10 hours to obtain solid polydimethylsiloxane. Then take it out of the container, and use laser cutting, micro-nano processing technology to prepare micro-needle molds, such as figure 1 shown.

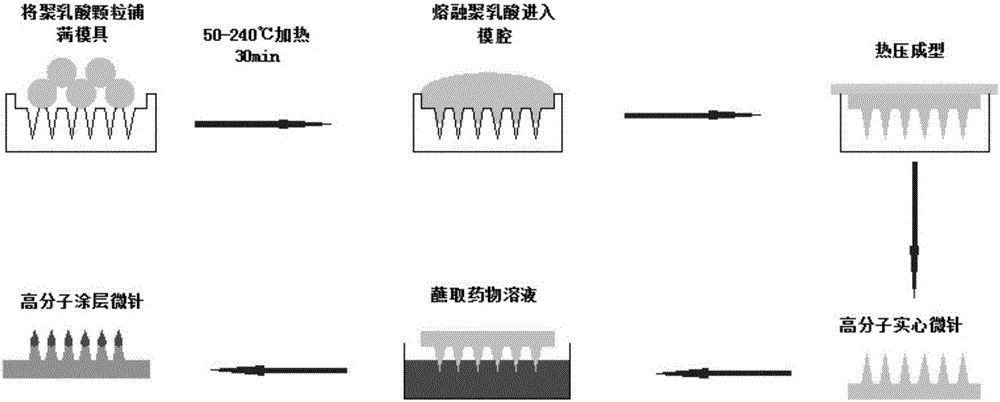

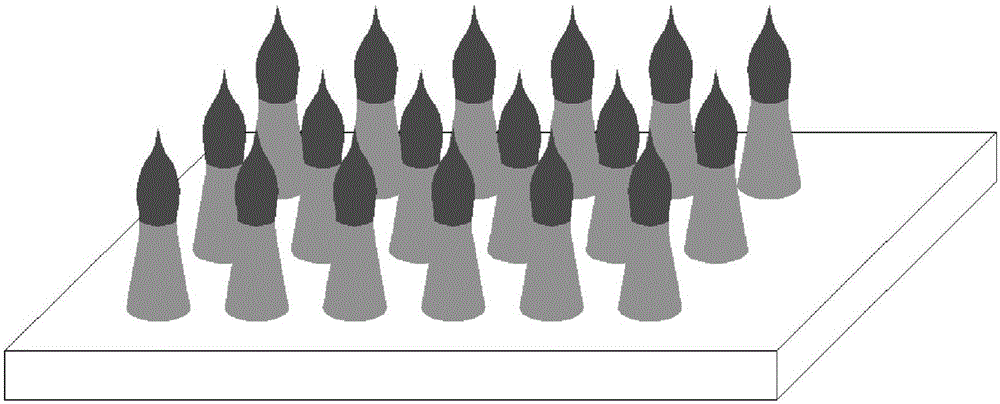

[0018] 2. Place the polylactic acid particles on the microneedle mold, heat and melt the polylactic acid particles at a high temperature of 200°C to make them all melt, and finally mold them while they are hot, and obtain polymer solid microneedles after cooling to room temperature. needle patch. The sulforhodamine B (sulforhodamine B) and polyvinyl alcohol, sucrose, and deionized water were prepared into a high-concentration solution according to the mass ratio of 0.015:4:...

Embodiment 2

[0021] 1. Mix polydimethylsiloxane and curing agent according to the mass ratio of 10:1, stir well and vacuumize to remove the air bubbles; then put the liquid polydimethylsiloxane containing curing agent to Pouring in a horizontally placed container, heating in an oven at 60°C for 5-10 hours to obtain solid polydimethylsiloxane, and then taking it out of the container, and using laser cutting, micro-nano processing technology to prepare microneedle molds.

[0022] 2. Place the polylactic acid (PLA) particles on the microneedle mold, heat and melt the polylactic acid particles at a high temperature of 200 ° C to make them all melt, and finally mold them while they are hot, and obtain a high-quality product after cooling to room temperature. Molecular solid microneedle patch.

[0023] 3. Mix sulforhodamine B (sulforhodamine B) with polyvinyl alcohol (PVA), trehalose, and deionized water according to the mass ratio of 0.005:4:6:10, 0.01:4:6:10, and 0.015:4:6, respectively :10,...

Embodiment 3

[0027] 1. Mix the polydimethylsiloxane and the curing agent according to the mass ratio of 10:1, stir well and remove the bubbles in it by vacuuming; then put the liquid polydimethylsiloxane containing the curing agent to Pouring in a horizontally placed container, heating in an oven at 60°C for 5-10 hours to obtain solid polydimethylsiloxane, and then taking it out of the container, and using laser cutting, micro-nano processing technology to prepare microneedle molds.

[0028] 2. Place the polylactic acid (PLA) particles on the microneedle mold, heat and melt the polylactic acid particles at a high temperature of 200 ° C to make them all melt, and finally mold them while they are hot, and obtain a high-quality product after cooling to room temperature. Molecular solid microneedle patch.

[0029] 3. Prepare penicillin, polyvinyl alcohol (PVA), glucose, and deionized water at a mass ratio of 0.015:4:6:10 to make a high-concentration solution.

[0030] 4. Dip the needle body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com