A kind of preparation method of composite decolorizing flocculant used for printing and dyeing wastewater treatment

A technology for decolorizing flocculants and printing and dyeing wastewater is applied in the field of preparation of composite decolorizing flocculants, which can solve the problems of high treatment cost, unutilized acid, limited adsorption capacity, etc., and achieves improved removal effect and excellent decolorization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

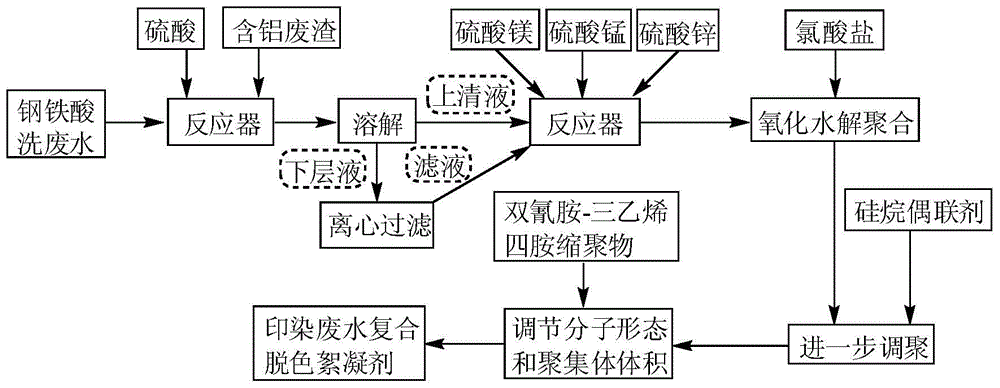

[0032] The preparation process block diagram of the present invention is as figure 1 shown.

[0033] Examples 1-10 are preparation examples of the composite decolorizing flocculant for printing and dyeing wastewater, and Examples 11-12 are application examples of the composite decolorizing flocculant for printing and dyeing wastewater.

[0034] The component content of iron and steel pickling waste water in the embodiment 1~4 is: total iron concentration is 2.45mol / L, ferrous concentration is 2.25mol / L, H + Concentration is 1.24mol / L, density ρ=1.19g / cm 3 ; The content of each component of the aluminum-containing waste slag is: the mass fraction of aluminum hydroxide is 55%, Cu 2+ The mass fraction is 0.01%, Cr 3+ The mass fraction is 0.12%, Ni 2+ The mass fraction is 0.05%, Zn 2+ The mass fraction is 0.03%.

[0035] The component content of iron and steel pickling waste water in embodiment 5~7 is: total iron concentration is 2.56mol / L, ferrous concentration is 2.34mol / L...

Embodiment 1

[0038] (1) Add 6kg of iron and steel pickling waste water and 0.516kg of mass fraction of 98% sulfuric acid into a 10L acid-resistant closed reactor, then add 0.240kg of aluminum-containing waste slag from aluminum processing, heat up to 90°C and stir until dissolved, statically The supernatant is transferred to a 50L acid-resistant closed reactor, and the liquid containing insoluble slag in the lower layer is transferred to the reactor after being centrifuged to filter the residue by a centrifuge;

[0039] (2) Add 11.4kg magnesium sulfate heptahydrate, 1.2kg manganese sulfate monohydrate and 1.2kg zinc sulfate heptahydrate to the above-mentioned 50L acid-resistant closed reactor, add 16L water, heat up to 80°C and stir until the solid matter is completely dissolved; then add After oxidative hydrolysis of 200g of sodium chlorate for 1 hour, slowly add 135.6g of γ-aminopropyltriethoxysilane and continue the reaction at 70°C for 3 hours;

[0040] (3) Lower the temperature to 40°...

Embodiment 2

[0042] (1) Add 6kg of steel pickling wastewater and 0.552kg of sulfuric acid with a mass fraction of 98% into a 10L acid-resistant closed reactor, then add 0.300kg of aluminum-containing waste slag from aluminum material processing, heat up to 80°C and stir until dissolved, statically The supernatant is transferred to a 50L acid-resistant closed reactor, and the liquid containing insoluble slag in the lower layer is transferred to the reactor after being centrifuged to filter the residue by a centrifuge;

[0043] (2) Add 7.2kg magnesium sulfate heptahydrate, 0.6kg manganese sulfate monohydrate and 0.9kg zinc sulfate heptahydrate to the above-mentioned 50L acid-resistant closed reactor, add 15.5L water, heat up to 75°C and stir until the solid matter is completely dissolved; then After adding 149.8g of sodium chlorate for oxidative hydrolysis for 0.7h, slowly add 115.8g of γ-glycidyl etheroxypropyltrimethoxysilane and continue the reaction at 75°C for 2.5h;

[0044] (3) reduce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com