Flue gas SCR denitration urea catalytic hydrolysis ammonia production system and method

A technology of urea catalytic hydrolysis and urea, which is applied in the direction of ammonia preparation/separation, etc., can solve the problems of slow response rate of common urea hydrolysis technology systems, and achieve the effects of short hydrolysis reaction time, increased reaction speed, and less consumption of urea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

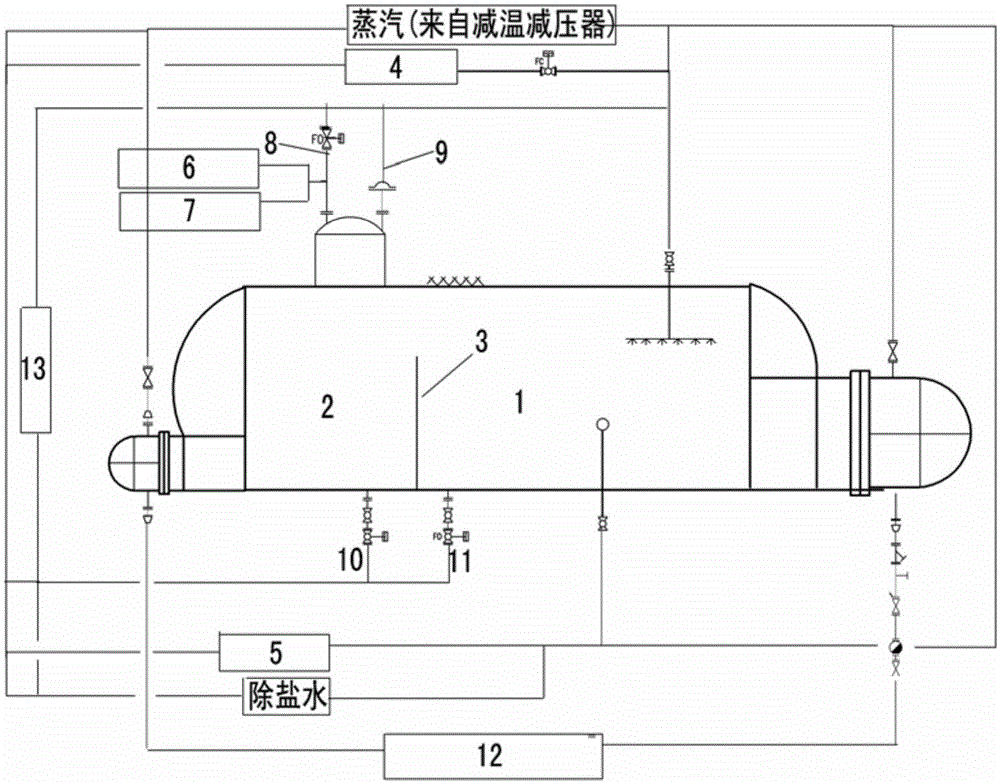

[0029] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] figure 1 A flow chart of a thermal power plant flue gas SCR denitrification urea catalytic hydrolysis ammonia production system provided by the present invention. The system includes a reaction system, a urea solution supply system, a steam supply system, an ammonia-air mixing system, a sewage system, a desalinated water system, a catalyst feeding system, a backflush system, a sewage discharge and a safety system.

[0031] The process of using the above system for flue gas SCR denitrification and urea catalytic hydrolysis to produce ammonia is as follows:

[0032] 1) The urea aqueous solution with a mass concentration of 50% is added to the reaction system from the urea solution storage tank (50-80°C heat preservation) 5 through the urea solution pipeline.

[0033] The reaction system has designed a double-chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com