Preparing method of graphene/carbon nanotube aerogel composite capacitive type desalting electrode

A carbon nanotube and graphene technology, which is applied in the field of preparation of graphene/carbon nanotube aerogel composite capacitive desalination electrodes, can solve the problems of poor electrical conductivity, low specific surface area, affecting desalination performance, etc., and achieves easy operation. , high specific surface area, good desalination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

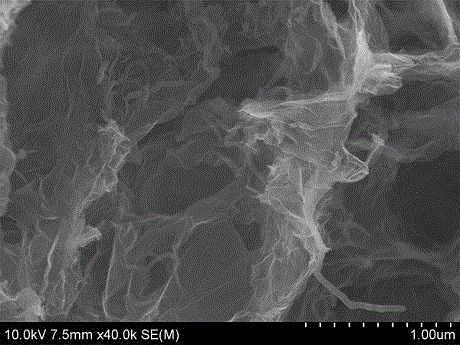

[0023] see figure 1 , this example provides a kind of preparation method of graphene / carbon nanotube airgel composite capacitive desalination electrode, it comprises the following steps:

[0024] Take 0.06g of graphite oxide and add 30mL of deionized water, mix and sonicate for 0.5h, the solid content of graphite oxide sol is 2mg / mL. Single-wall carbon nanotubes are added in the dispersion liquid of graphite oxide, and ultrasonic dispersion is uniform, and carbon nanotube: the mass ratio of graphite oxide is 1:9; After ultrasonic dispersion is uniform, add 0.29g ascorbic acid, 95 o C for 3 h; freeze-dry the obtained hydrogel, and then further reduce the aerogel under the protection of nitrogen atmosphere to prepare the graphene / carbon nanotube airgel composite material. Under the protection of nitrogen atmosphere, with 1 o C / min heating rate increased to 800 o C, keep warm for 3h, and the gas flow rate is 90mL / min. The prepared graphene / carbon nanotube composite material, ...

Embodiment 2

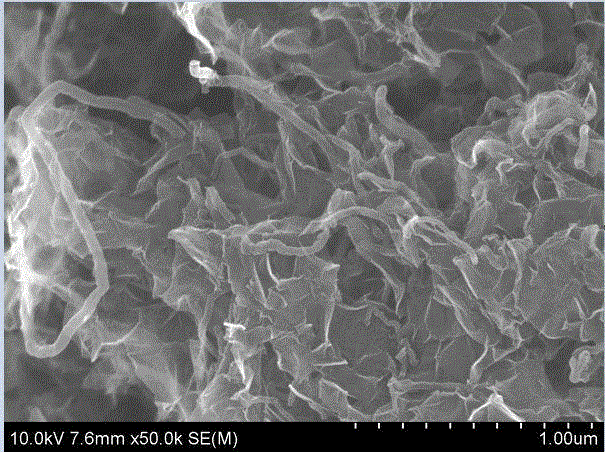

[0026] see figure 2 , this example provides a kind of preparation method of graphene / carbon nanotube airgel composite capacitive desalination electrode, it comprises the following steps:

[0027]Take 0.06g of graphite oxide and add 30mL of deionized water, mix and sonicate for 0.5h, the solid content of graphite oxide sol is 2mg / mL. Single-wall carbon nanotubes are added in the dispersion liquid of graphite oxide, ultrasonic dispersion is uniform, carbon nanotube: the mass ratio of graphite oxide is 1:6; After ultrasonic dispersion is uniform, add 0.29g ascorbic acid, 95 o C for 3 h; freeze-dry the obtained hydrogel, and then further reduce the aerogel under the protection of nitrogen atmosphere to prepare the graphene / carbon nanotube airgel composite material. Under the protection of nitrogen atmosphere, with 1 o C / min heating rate increased to 800 o C, keep warm for 3h, and the gas flow rate is 90mL / min. The prepared graphene / carbon nanotube composite material, conducti...

Embodiment 3

[0029] This example provides a kind of preparation method of graphene / carbon nanotube airgel composite capacitive desalination electrode, which comprises the following steps:

[0030] Take 0.06g of graphite oxide and add 30mL of deionized water, mix and sonicate for 0.5h, the solid content of graphite oxide sol is 2mg / mL. Double-walled carbon nanotubes are added in the dispersion liquid of graphite oxide, and ultrasonic dispersion is uniform, and the mass ratio of carbon nanotubes: graphite oxide is 1:4; After ultrasonic dispersion is uniform, add 0.18g hydroquinone, 80 o The reaction was carried out at C for 3 hours; the obtained hydrogel was freeze-dried, and then the airgel was further reduced under the protection of an inert gas atmosphere to obtain a graphene / carbon nanotube airgel composite material. Under the protection of nitrogen atmosphere, with 1 o C / min heating rate increased to 800 o C, keep warm for 3h, and the gas flow rate is 100mL / min. The prepared graphene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com