Integral composite oxide low-temperature SCR catalyst and preparation method thereof

A composite oxide, monolithic technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems that do not involve the preparation and performance of monolithic catalysts, difficult to control, complicated operation process, etc. Excellent resistance to SO2 and water vapor, reducing mass and volume, and promoting the effect of SCR reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

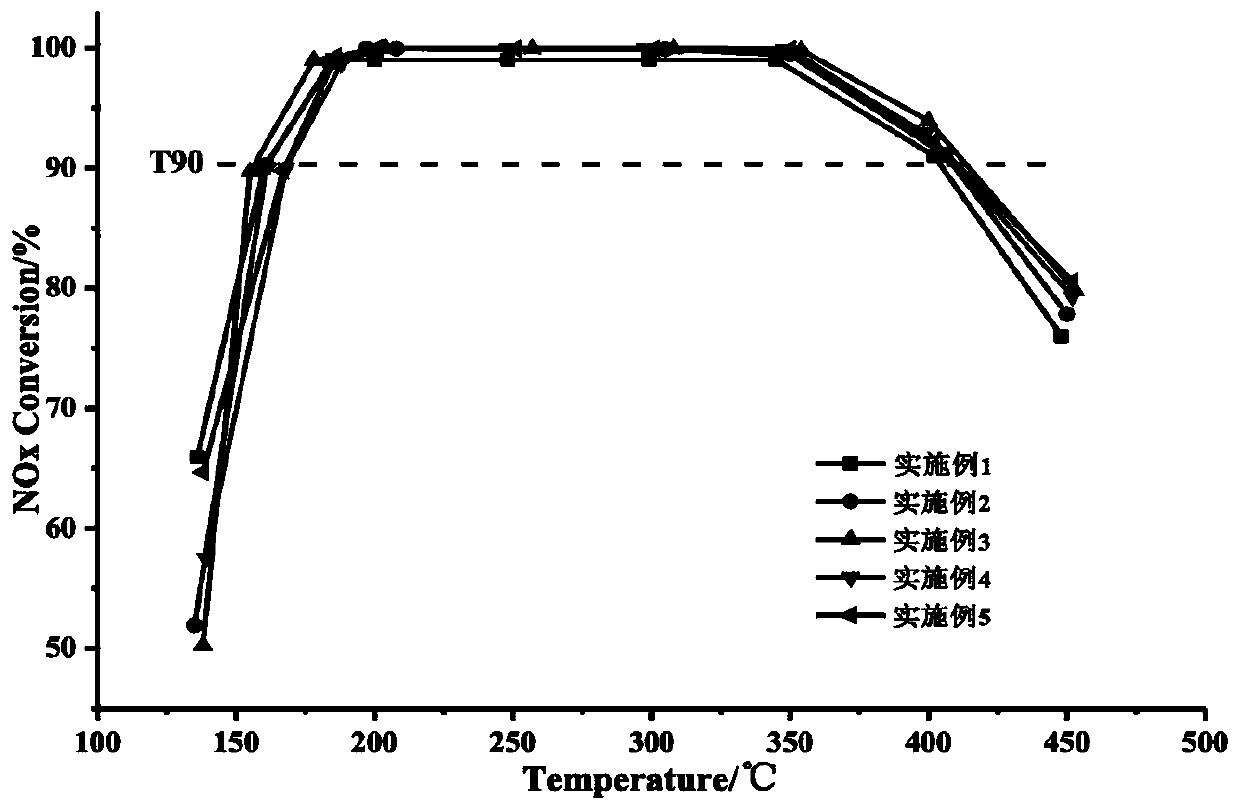

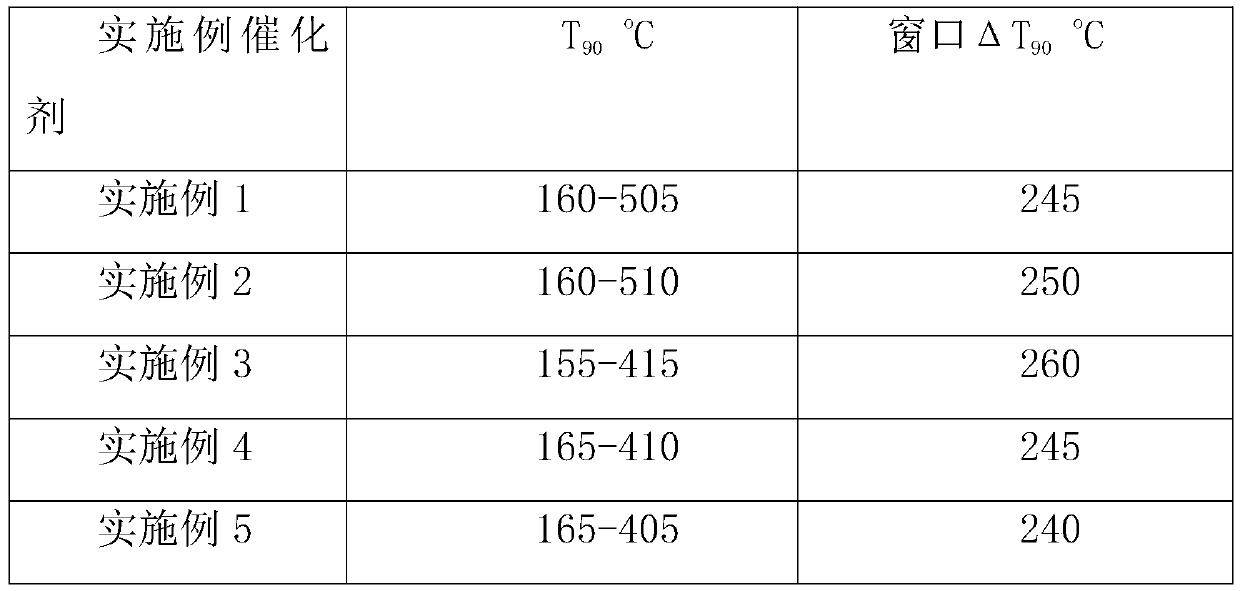

Examples

Embodiment 1

[0039] A monolithic composite oxide low-temperature SCR catalytic module, prepared by the following method:

[0040] S1. Vector preparation

[0041] Composite the corrugated fiberglass base material with the flat glass fiber base material and process it into a carrier module.

[0042] S2, catalyst active powder

[0043] S21, dissolving 10 parts of Mn and 1 part of Fe precursor into 80 parts of deionized water, stirring until completely dissolved, to obtain an active solution;

[0044] S22. Add 100 parts of ZSM-5 molecular sieves to the active solution in S21, stir ultrasonically for 4 hours, dry at 100° C., and calcinate at 550° C. for 4 hours in an air atmosphere to obtain an active powder.

[0045] S3, catalyst coating

[0046] S31. Mix 10 parts of silica sol, 0.2 parts of glycerin and 80 parts of deionized water, then add 100 parts of active powder, stir, and ball mill for 60 minutes to obtain a coating slurry.

[0047] S32. Put the monolithic carrier in the coating slu...

Embodiment 2

[0050] A monolithic composite oxide low-temperature SCR catalytic module, prepared by the following method:

[0051] S1. Vector preparation

[0052] Composite the corrugated fiberglass base material with the flat glass fiber base material and process it into a carrier module.

[0053] S2, catalyst active powder

[0054] S21, dissolving 15 parts of Mn and 3 parts of Cu precursors into 90 parts of deionized water, stirring until completely dissolved, to obtain an active solution;

[0055]S22. Add 100 parts of CHA molecular sieves to the active solution of S21, stir ultrasonically for 4 hours, dry at 120° C., and calcinate at 550° C. for 6 hours in an air atmosphere to obtain an active powder.

[0056] S3, catalyst coating

[0057] S31. Mix 20 parts of aluminum sol, 4 parts of ammonium dodecylbenzenesulfonate and 75 parts of deionized water, then add 100 parts of active powder, stir, and ball mill for 30 minutes to obtain a coating slurry.

[0058] S32. Put the monolithic car...

Embodiment 3

[0061] A monolithic composite oxide low-temperature SCR catalytic module, prepared by the following method:

[0062] S1. Vector preparation

[0063] Composite the corrugated fiberglass base material with the flat glass fiber base material and process it into a carrier module.

[0064] S2, catalyst active powder

[0065] S21, dissolving 10 parts of Mn and 1 part of Ce precursor into 80 parts of deionized water, stirring until completely dissolved, to obtain an active solution;

[0066] S22. Add 100 parts of BEA molecular sieves to the active solution of S21, perform ion exchange at 70° C. for 4 hours, dry at 80° C., and calcinate at 450° C. for 6 hours in an air atmosphere to obtain an active powder.

[0067] S3, catalyst coating

[0068] S31. Mix 18 parts of silica sol, 1.0 part of polyethylene glycol, 0.3 part of glycerin and 85 parts of deionized water, then add 100 parts of active powder, stir, and ball mill for 120 minutes to obtain a coating slurry.

[0069] S32. Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com