Non-cement ceramic tile adhesive

A ceramic tile adhesive, cement-free technology, applied in the field of building materials, can solve the problems of difficult to achieve tile adhesive performance, non-renewable resource consumption, environmental pollution, etc., and achieves the effects of low maintenance conditions, environmental protection, and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A cement-free tile adhesive consisting of a cement-free mortar masterbatch and additives;

[0024] The cement-free mortar masterbatch is composed of the following components by mass percentage: 31% ultrafine fly ash, 57.2% river sand, 9.3% lime and 2.5% gypsum; the particle size of the ultrafine fly ash is 5- 10μm;

[0025] The additives include 2.50% of redispersible latex powder, 0.35% of cellulose ether, 0.15% of water reducer, 0.10% of water repellent, and 0.40% of early strength agent; Quality is the benchmark measure.

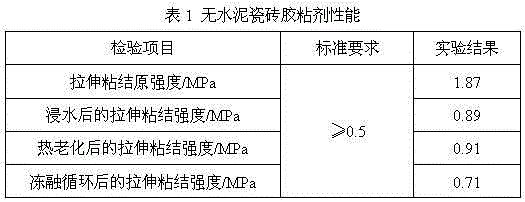

[0026] The cement-free tile adhesive prepared in the present embodiment is detected, and its detection data are as shown in Table 1:

[0027]

[0028] Its various properties meet the technical requirements of the standard "Ceramic Wall and Floor Tile Adhesive" (JC / T547-2005).

Embodiment 2

[0030] A cement-free tile adhesive consisting of a cement-free mortar masterbatch and additives;

[0031] The cement-free mortar masterbatch is composed of the following components by mass percentage: 28% ultra-fine fly ash, 67% river sand, 4% lime and 1% gypsum; the particle size of the ultra-fine fly ash is 5- 10μm;

[0032] The additives include 4.00% of redispersible latex powder, 0.40% of cellulose ether, 0.30% of water reducer, 0.05% of water repellent, and 0.30% of early strength agent; Quality is the benchmark measure.

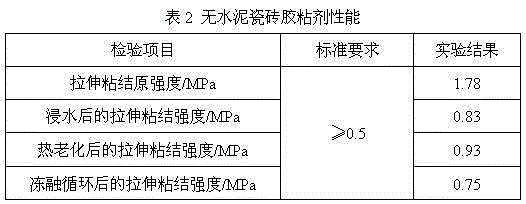

[0033] The cement-free tile adhesive prepared in the present embodiment is detected, and its detection data are as shown in Table 2:

[0034]

[0035] Its various properties meet the technical requirements of the standard "Ceramic Wall and Floor Tile Adhesive" (JC / T547-2005).

Embodiment 3

[0037] A cement-free tile adhesive consisting of a cement-free mortar masterbatch and additives;

[0038] The cement-free mortar masterbatch is composed of the following components by mass percentage: 30.5% ultra-fine fly ash, 60% machine-made sand, 7.5% lime and 2% gypsum; the particle size of the ultra-fine fly ash is 5- 10μm;

[0039] The additives include 4.50% of redispersible latex powder, 0.40% of cellulose ether, 0.10% of water reducer, 0.20% of water repellent, and 0.40% of early strength agent; Quality is the benchmark measure.

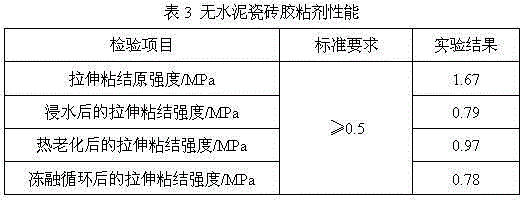

[0040] The cement-free tile adhesive prepared in the present embodiment is detected, and its detection data are as shown in Table 3:

[0041]

[0042] Its various properties meet the technical requirements of the standard "Ceramic Wall and Floor Tile Adhesive" (JC / T547-2005).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com