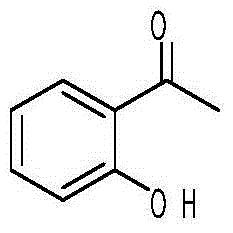

Preparation method of 2-hydroxyacetophenone

A technology of o-hydroxyacetophenone and phenol, applied in the field of preparation of o-hydroxyacetophenone and o-hydroxyacetophenone, can solve the problems of low yield, complicated preparation method and process, and achieves high yield, low cost, The effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

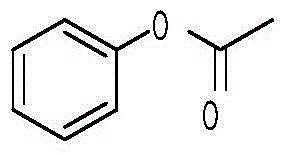

[0032] 1) Preparation of phenol acetate

[0033] Add 14.1g (0.15mol) of phenol, 14.13g (0.18mol) of acetyl chloride, and 40ml of cyclohexane into a three-neck flask, and react at room temperature for 2-3 hours. After the plate reaction is completed, adjust the pH to about 8 with sodium bicarbonate solution. The organic phase was collected and dried over anhydrous sodium sulfate to obtain 20.2 g of the product light yellow oily liquid phenol acetate (yield 99%).

[0034] 2) the preparation of o-hydroxyacetophenone

[0035] a. Add 13.6g (0.1mol) of phenol acetate in a three-necked flask, add 16g (0.12mol) of aluminum trichloride, heat and reflux at 120°C for 1.5h, after the plate reaction is completed, add 50ml of mass fraction of 5% hydrochloric acid solution, extracted 3 times with ethyl acetate, collected the organic phase, extracted with the second organic solvent; concentrated the organic layer, added 1-2 times the volume of the third organic solvent, the organic layer was...

Embodiment 2

[0040] 1) Preparation of phenol acetate

[0041] Add 14.1g (0.15mol) of phenol, 14.13g (0.18mol) of acetyl chloride, and 240ml of chloroform into a three-neck flask, and react at room temperature for 2-3 hours. After the plate reaction is completed, adjust the pH to about 8 with sodium bicarbonate solution. Collect the organic phase and dry it over anhydrous sodium sulfate to obtain 12.05 g of product light yellow oily liquid phenol acetate (yield 59%)

[0042] 2) the preparation of o-hydroxyacetophenone

[0043] a. Add 13.61g (0.1mol) of phenol acetate to a three-necked flask, add 16g (0.12mol) of aluminum trichloride, heat and reflux at 130°C for 1.5h, after the plate reaction is complete, add 50ml of mass fraction to 5 % hydrochloric acid solution, extracted 3 times with ethyl acetate, concentrated the organic layer, added 1-2 times the volume of the third organic solvent, the organic layer was frozen and filtered, and the operation was repeated 2-3 times to obtain the fil...

Embodiment 3

[0047] 1) Preparation of phenol acetate

[0048] Add 14.1g (0.15mol) of phenol, 14.13g (0.18mol) of acetyl chloride, and 40ml of toluene into a three-necked flask, and react at room temperature for 2-3h. After the plate reaction is completed, adjust the pH to about 8 with sodium bicarbonate solution. Collect the organic phase and dry it over anhydrous sodium sulfate to obtain 17.77 g (yield 87%) of product light yellow oily liquid phenol acetate

[0049] 2) the preparation of o-hydroxyacetophenone

[0050] a. Add 13.6 g (0.1 mol) of phenol acetate in a three-necked flask, add 16 g (0.12 mol) of aluminum trichloride, heat and reflux at 140 ° C for 1.5 h, and after the plate reaction is complete, add 50 ml with a mass fraction of 5% hydrochloric acid solution, extract 3 times with ethyl acetate, concentrate the organic layer, add 1-2 times the volume of the third organic solvent, freeze the organic layer, filter, repeat the operation 2-3 times, the obtained filter cake, The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com