Preparation method of 2-amino-4, 6-dimethoxy pyrimidine

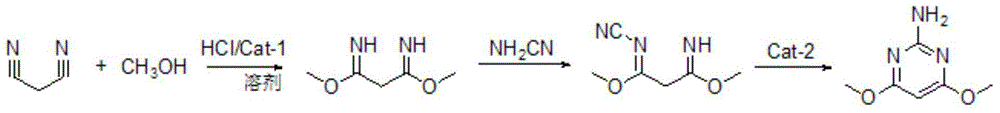

A technology of dimethoxypyrimidine and dimethoxypropanediamidine, which is applied in the field of preparation of 2-amino-4,6-dimethoxypyrimidine, can solve potential safety hazards, product instability when exposed to heat, and dust deterioration. Operating environment and other issues, to achieve the effect of less waste, significant social and economic benefits, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of Dimethoxypropanediamidine (ADMP01)

[0031] In a 3000L glass-lined kettle, add metered 1800L toluene and catalyst 10kg (DMF) through the head tank, start stirring, turn on frozen brine, and cool down to below -5°C; then add the prepared malononitrile-methanol into the kettle Solution (200kg malononitrile and 300L methanol), open the dried hydrogen chloride ventilation valve, pass hydrogen chloride into the kettle, control the temperature at no more than 25°C, react for 10 hours, and take samples for central control; after the central control is qualified, put in the next step response.

[0032] 2. Preparation of 3-amino-3-methoxy-N-cyano-2-propionamidine (ADMP02)

[0033] In a 3000L glass-lined kettle, add 1000L of water, 510kg of cyanamide with a mass concentration of 30%, 1kg of disodium hydrogen phosphate and 350kg of sodium bicarbonate, cool down to -5°C, and prepare the 1,3-dimethoxy Slowly put the propylenediimine dihydrochloride solution into ...

Embodiment 2

[0040] 1. Preparation of Dimethoxypropanediamidine (ADMP01)

[0041] In a 3000L glass-lined kettle, add metered 1800L dichloroethane and catalyst 10kg (DMSO) through the head tank, start stirring, turn on frozen brine, and cool down to below -5°C; then add the prepared propanediol into the kettle Nitrile-methanol solution (200kg malononitrile and 300L methanol), open the dried hydrogen chloride ventilation valve, pass hydrogen chloride into the kettle, control the temperature at no more than 25°C, react for 15 hours, and take samples for central control; after the central control is qualified , put into the next step reaction.

[0042] 2. Preparation of 3-amino-3-methoxy-N-cyano-2-propionamidine (ADMP02)

[0043] In the 3000L glass-lined still, add 1000L water, 510kg mass concentration and be 30% cyanamide, 1kg disodium hydrogen phosphate and 350kg sodium bicarbonate, be cooled to-5 ℃, the 1,3-dimethoxy that last step is prepared Put the propylenediimine dihydrochloride solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com