Preparation method for high-purity tedizolid phosphate

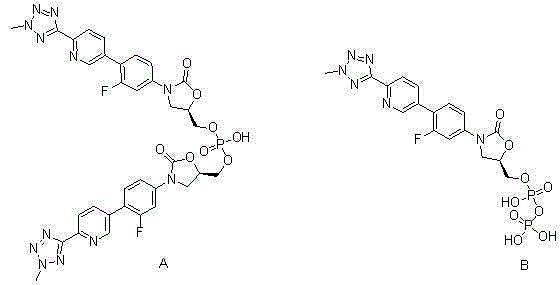

A technology of tedizolid phosphate and tedizolid, which is applied in the field of preparation of high-purity tedizolid phosphate, can solve the impact of tedizolid phosphate application effect and production efficiency, and it is difficult to obtain high-purity tedizolid phosphate. Problems such as poor stability of dizolid phosphate and phosphorus oxychloride intermediates have achieved high market promotion value, easy promotion and application, and less post-processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

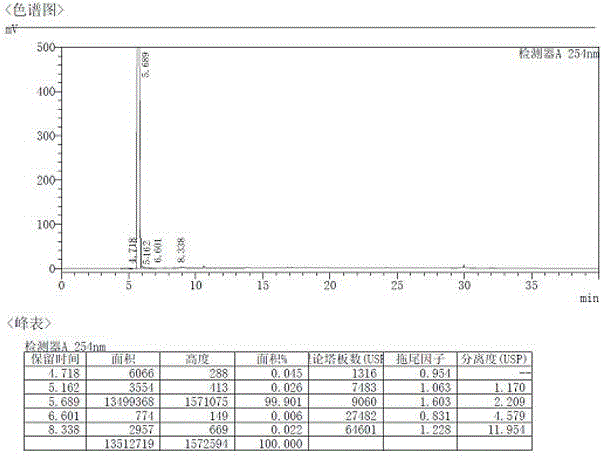

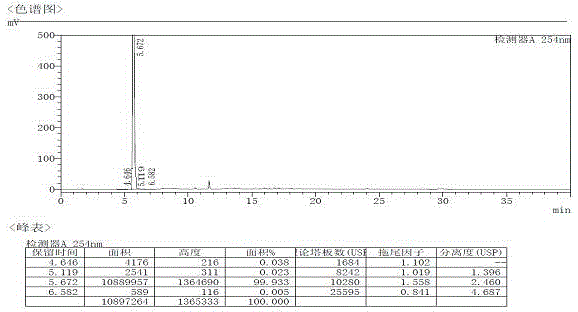

Embodiment 1

[0026] Add 37.0g tedizolid, 400ml tetrahydrofuran, and 12.9g DIPEA into a three-necked flask, and ice-bath until the inner temperature is 0 o C, stir, slowly drop 15.3g phosphorus oxychloride, control temperature o C, after the dropwise addition, naturally warming up to 20 oC , continue to stir for 4h, TLC detects that the raw material disappears, and a solution of the phosphoryl chloride tedizolid intermediate is obtained.

[0027] Add 25.9g DIPEA to the upper solution, cool to 0 o C, stir, slowly drop 21.6g benzyl alcohol, control the temperature o C, after the dropwise addition, naturally warming up to 20 oC , continue to stir for 8h, TLC detects that the raw materials disappear, filter, add 200ml ethyl acetate to the filter cake for recrystallization, filter, and filter the cake at 40 oC Vacuum drying for 10 hours gave a total of 52.3 g of dibenzyl phosphate tedizolid intermediate, with a yield of 83%. The nuclear magnetic resonance data of the dibenzyl phosphate tedizo...

Embodiment 2

[0030] Add 74.1g tedizolid, 800ml tetrahydrofuran, and 25.9g DIPEA into the three-necked flask, and ice-bath until the inner temperature is 0 o C, stir, slowly drop 30.7g phosphorus oxychloride, control temperature o C, after the dropwise addition, naturally warming up to 20 oC , continue to stir for 4h, TLC detects that the raw material disappears, and a solution of the phosphoryl chloride tedizolid intermediate is obtained.

[0031] Add 51.7g DIPEA to the upper solution, cool to 0 o C, stir, slowly drop 43.3g benzyl alcohol, control the temperature o C, after the dropwise addition, naturally warming up to 20 oC , continue to stir for 8h, TLC detects that the raw materials disappear, filter, add 400ml ethyl acetate to the filter cake for recrystallization, filter, and filter the cake at 40 oC Vacuum drying for 10 hours gave a total of 105.9 g of dibenzyl phosphate tedizolid intermediates, with a yield of 84%. The nuclear magnetic resonance data of the dibenzyl phosphate te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com