Adjusting liquid used for circuit board manufacturing and preparation method thereof

A circuit board and adjustment liquid technology, applied in the field of printed circuit manufacturing, can solve the problems of high price of adjustment liquid and high price, and achieve the effects of good adjustment effect, stable yield and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

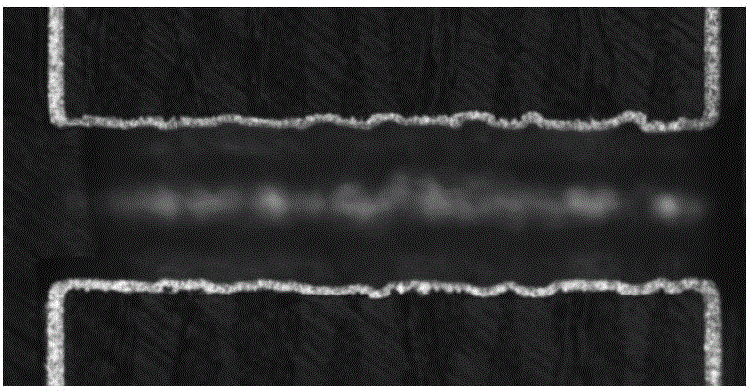

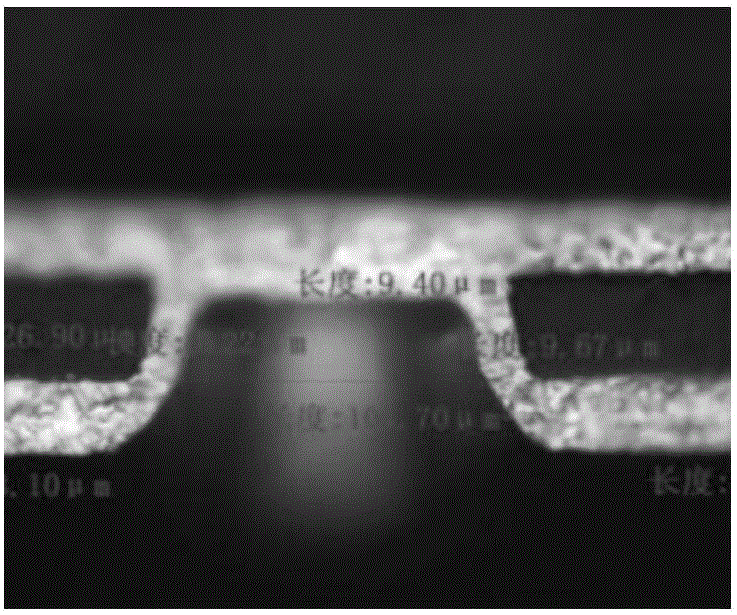

Image

Examples

Embodiment 1

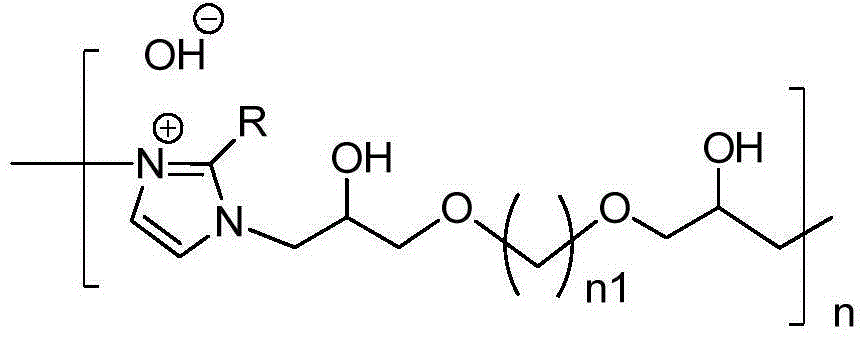

[0034] Put 10.0g (69.3mmol) of 2-phenylimidazole, 20mL of water, 10mL of ethanol, and 0.5g of 50% sulfuric acid in a 100ml three-necked flask, put the flask in a 60°C oil bath, and pass it through a constant pressure dropping funnel under stirring Slowly add 11.0g (63.0mmol) of ethylene glycol diglycidyl ether, continue to stir for half an hour, increase the temperature of the oil bath to 90°C, and reflux for 20 hours to obtain a brown-red transparent liquid, which is the cationic surfactant solution.

Embodiment 2

[0036] Put 10.0g (69.3mmol) of 2-phenylimidazole, 24mL of water, 12mL of acetone, and 0.5g of 50% sulfuric acid into a 100ml three-necked flask, put the flask in a 60°C oil bath, and pass it through a constant pressure dropping funnel under stirring Slowly add 12.7g (63.0mmol) 1,4-butanediol diglycidyl ether, continue stirring for half an hour, increase the temperature of the oil bath to 85°C, and reflux for 24 hours to obtain a brownish-red transparent liquid, which is the cationic surfactant solution .

Embodiment 3

[0038] Put 10.0g (69.3mmol) of 2-phenylimidazole, 24mL of water, 12mL of N-methylpyrrolidone, and 0.5g of 50% sulfuric acid into a 100ml three-necked flask. Slowly add 12.7g (63.0mmol) 1,4-butanediol diglycidyl ether into the dropping funnel, continue stirring for half an hour, increase the temperature of the oil bath to 95°C, and reflux for 18 hours to obtain a brown-red transparent liquid, which is the cationic surface active agent solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com