A kind of three-dimensional braided composite automobile leaf spring and its preparation method

A composite material and three-dimensional weaving technology, which is applied to leaf springs, mechanical equipment, springs/shock absorbers, etc., can solve problems such as high processing difficulty, weak interlayer bonding strength, and low design flexibility, so as to improve product quality. Quality and service life, long service life, effect of improved running characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

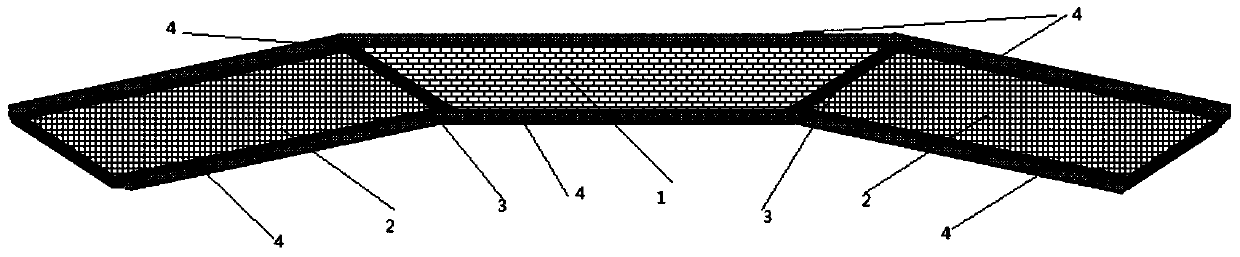

Image

Examples

Embodiment 1

[0040] (1) According to the load requirements of the vehicle, a hybrid combination of high-performance carbon fiber and glass fiber is selected to prepare tow for three-dimensional fabric weaving. The weight ratio of carbon fiber yarn to glass fiber yarn is 1:1. After the yarn is matched to form a mixed yarn, the surface treatment is carried out. The treatment adopts vacuum high-temperature degumming to remove the sizing agent on the surface of the mixed fiber, and then winds it according to the requirements of the three-dimensional knitting machine.

[0041] (2) Combination of hybrid fibers and preparation of three-dimensional braided structures. Aramid fiber yarn is selected for winding. The wound carbon fiber / glass fiber mixed yarn and aramid fiber yarn were assembled on a three-dimensional braiding machine to prepare a hybrid fiber three-dimensional fabric for leaf springs.

[0042] (3) Fabric structure design. According to the requirements of the load-carrying vehicle,...

Embodiment 2

[0051] (1) According to the load requirements of the vehicle, a hybrid combination of high-performance carbon fiber and glass fiber is selected to prepare tow for three-dimensional fabric weaving. The weight ratio of carbon fiber yarn to glass fiber yarn is 3:1. After the yarn is matched to form a mixed yarn, it is surface-treated. The treatment usually uses a high-temperature degumming in an argon atmosphere to remove the sizing agent on the surface of the mixed fiber, and then it is wound up according to the requirements of the three-dimensional knitting machine.

[0052] (2) Select aramid fiber and UHMWPE fiber respectively to combine into mixed yarn for winding. After assembling the above wound carbon fiber / glass fiber mixed yarn, aramid fiber and UHMWPE fiber yarn on a three-dimensional braiding machine, a hybrid fiber three-dimensional fabric for leaf springs is prepared.

[0053] (3) According to the use requirements of the truck, select the appropriate fiber yarn mate...

Embodiment 3

[0062] (1) According to the load requirements of the vehicle, a hybrid combination of high-performance carbon fiber and glass fiber is selected to prepare tow for three-dimensional fabric weaving. The weight ratio of carbon fiber yarn to glass fiber yarn is 5:1. After the yarn is matched to form a mixed yarn, the surface treatment is carried out. The treatment usually uses a high-temperature vacuum atmosphere to remove the sizing agent on the surface of the mixed fiber, and then it is wound up according to the requirements of the three-dimensional knitting machine.

[0063] (2) UHMWPE fibers are selected for yarn winding respectively. After assembling the above-mentioned wound carbon fiber / glass fiber mixed yarn and UHMWPE fiber yarn on a three-dimensional braiding machine, a hybrid fiber three-dimensional fabric for leaf springs is prepared.

[0064] (3) According to the use requirements of the truck, select the appropriate fiber yarn material and weaving structure at the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com