Preparation method of GaN-based light-emitting diode chip

A technology of light-emitting diodes and chips, applied in the field of optoelectronics, can solve problems such as leakage of diodes that cannot be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

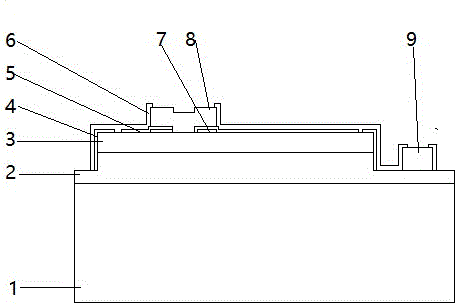

[0023] The preparation method of the GaN-based light-emitting diode chip of the present invention is suitable for the GaN-based light-emitting diode chip of the sapphire substrate that is installed, and the specific steps are as follows:

[0024] (1) First, coat 2- 6 μm (preferably 3 μm) thick positive photoresist, photolithography is carried out on the positive photoresist, and the pattern (the pattern of the desired mesa structure) that can be etched out of the mesa structure by subsequent ICP;

[0025] The photolithography process of the positive photoresist is completed through the steps of alignment, exposure, development, and drying: use a hot plate to bake at 98°C for 1 minute to 2 minutes for alignment, and then expose to ultraviolet light for 5 minutes. seconds to 20 seconds, and then developed with tetramethylammonium hydroxide for 10 seconds to 30 seconds after drying, and baked at 98°C for 1 to 2 minutes by using a hot plate.

[0026] (2) Utilize the ICP dry etchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com