Preparation method of self-foaming porous composite bone repair bracket

A self-foaming and bone repair technology, applied in the fields of medical science, tissue regeneration, prosthesis, etc., can solve the problems of difficulty in mixing foaming agent water evenly, difficulty in applying composite porous scaffolds, and affecting the uniformity of pore structure of scaffolds. Simple and easy to implement, meet the requirements, and have broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

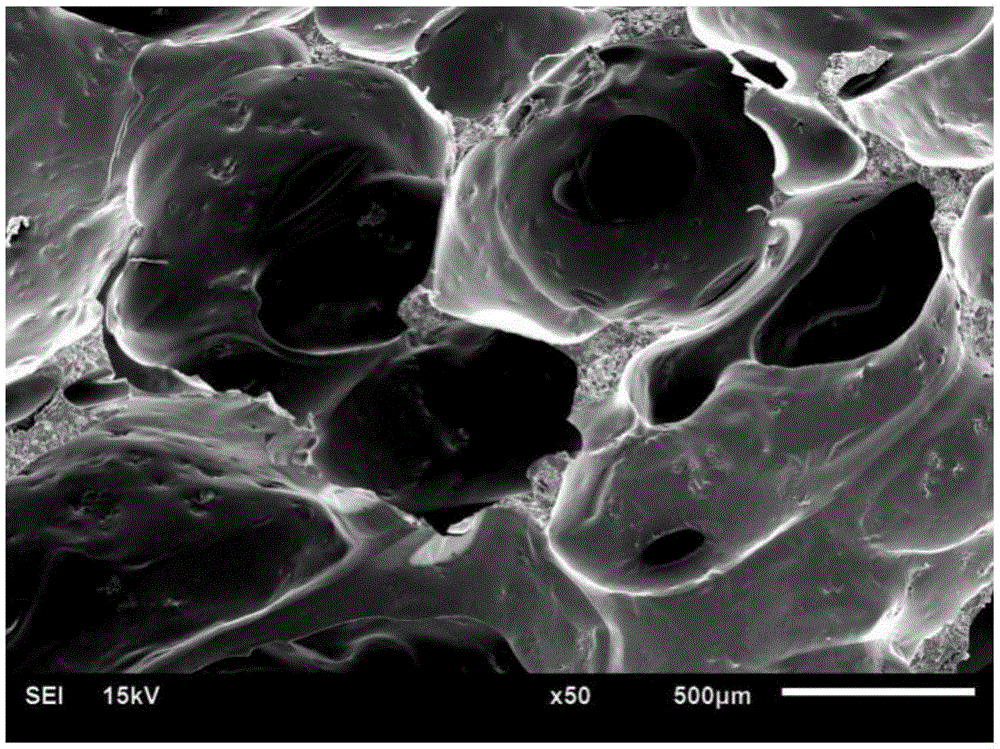

Embodiment 1

[0023] According to the method reported by Li Limei et al. "Interfacial structure and mechanical properties of alcohol-modified castor oil-based polyurethane / n-HA composite scaffold material" (Journal of Inorganic Materials, 2013, 28(8):811-817), crystallize with calcium hydrogen phosphate The hydrate replaces the nano-hydroxyapatite in the literature to prepare the calcium hydrogen phosphate-polyurethane composite material prepolymer, and then adds the chain extender 1,4-butanediol and continues to react for a period of time to obtain a viscous composite material. In the calcium hydrogen phosphate-polyurethane composite material, the crystalline hydrate of calcium hydrogen phosphate is about 30wt%, corresponding to about 6wt% of bound water as a foaming agent, and the viscous calcium hydrogen phosphate-polyurethane composite material is put into the mold, Curing and foaming at 90°C for 24 hours. After curing, a self-foaming porous composite bone repair scaffold is obtained. ...

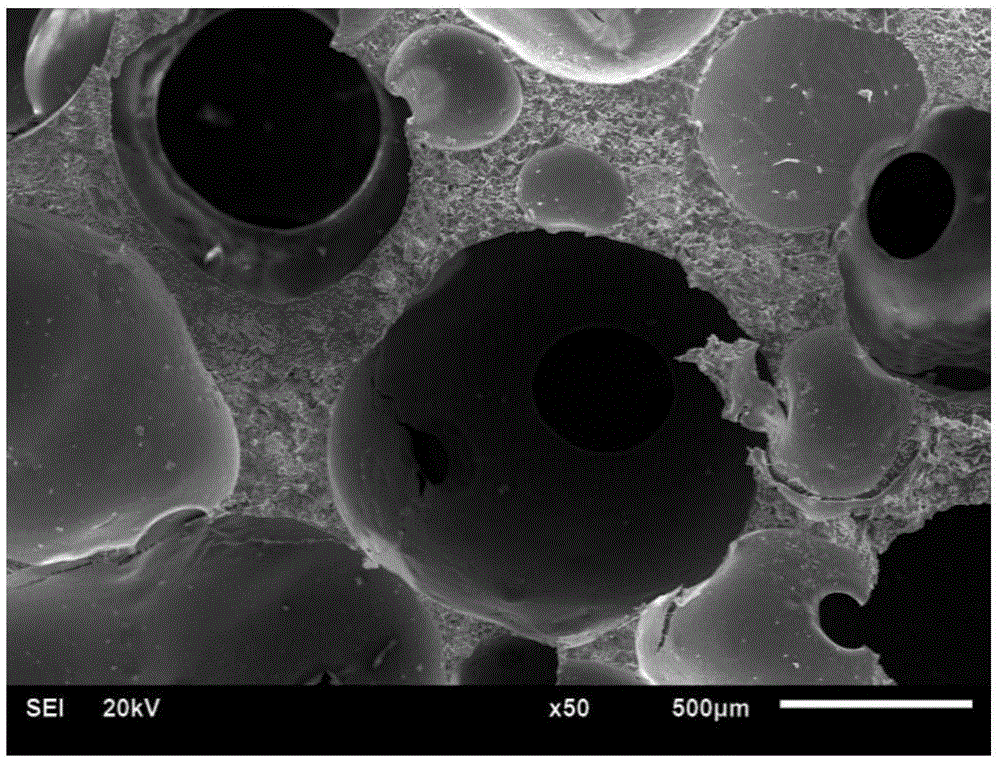

Embodiment 2

[0025] According to the method reported in the literature described in Example 1, the calcium hydrogen phosphate crystalline hydrate is used to replace the nano-hydroxyapatite in the literature to prepare the calcium hydrogen phosphate-polyurethane composite material prepolymer, and then add the chain extender 1,4- Continue to react for a period of time after butanediol to obtain a viscous composite material. In the calcium hydrogen phosphate-polyurethane composite material, the crystalline hydrate of calcium hydrogen phosphate is about 40wt%, and correspondingly contains about 8wt% bound water as a blowing agent. The viscous calcium hydrogen phosphate-polyurethane composite material was put into the mold, and aged and foamed at 110°C for 4 hours. After curing, a self-foaming porous composite bone repair scaffold is obtained.

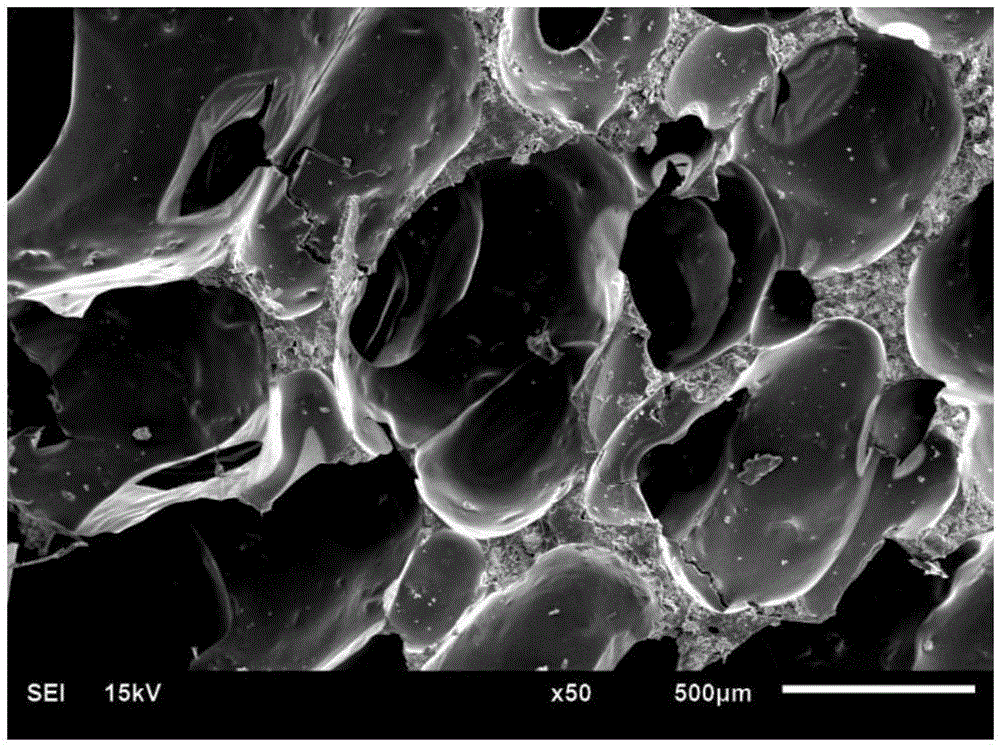

Embodiment 3

[0027] According to the method reported in the literature described in Example 1, the calcium hydrogen phosphate crystalline hydrate is used to replace the nano-hydroxyapatite in the literature to prepare the calcium hydrogen phosphate-polyurethane composite material prepolymer, and then add the chain extender 1,4- Continue to react for a period of time after butanediol to obtain a viscous composite material. In the calcium hydrogen phosphate-polyurethane composite material, the crystalline hydrate of calcium hydrogen phosphate is about 10wt%, and correspondingly contains about 2wt% bound water as a blowing agent. The viscous calcium hydrogen phosphate-polyurethane composite material is put into the mold and aged and foamed at 100°C for 12 hours. After curing, a self-foaming porous composite bone repair scaffold is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com