Safe ignition powder and preparation method thereof

A safety point and gunpowder technology, applied in explosives, offensive equipment, inorganic oxyhalide salt explosive composition, etc., can solve the problems of single types of hydrogen storage materials and unsatisfactory applications, and achieve simple preparation process, simple and easy operation, The effect of reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

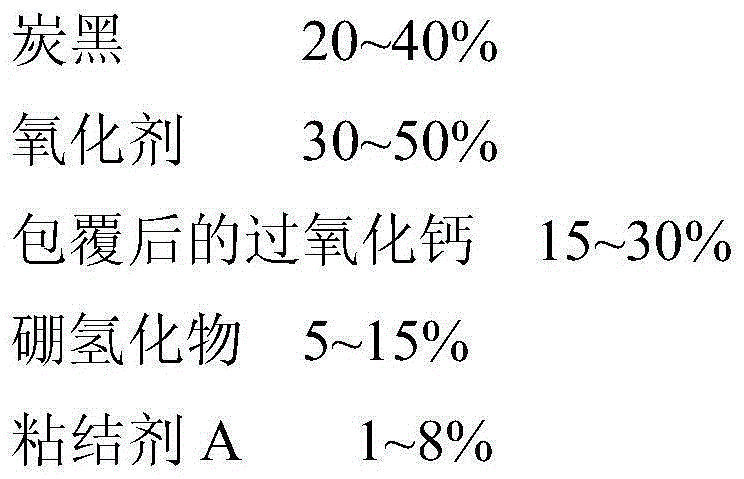

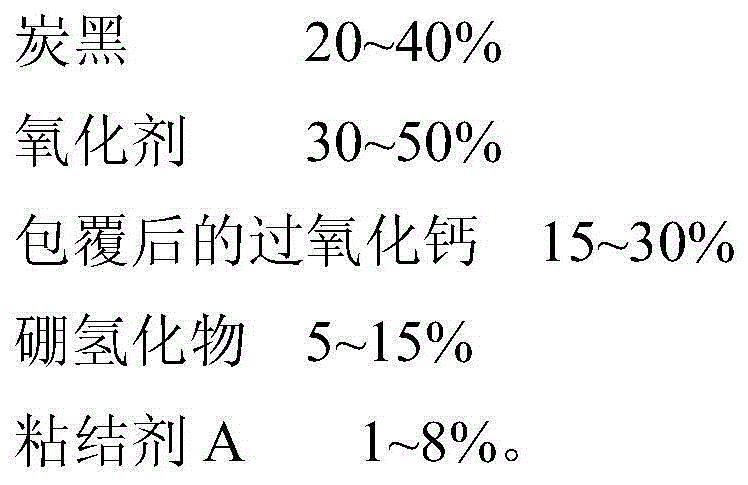

Method used

Image

Examples

Embodiment 1

[0029] A safe ignition powder, the mass of each component in the formula is: 20g carbon black, 45g potassium nitrate, 10g lithium borohydride, 24g coated calcium peroxide and 1g hydroxyl-terminated polybutadiene.

[0030] A kind of preparation method of safety ignition powder, concrete steps are as follows:

[0031] 1) 0.5g styrene is dissolved in anhydrous tetrahydrofuran, completely dissolved to form a liquid glue with a mass fraction of 0.5%;

[0032] 2) Add 80g of calcium peroxide to 300ml of anhydrous tetrahydrofuran, clean and vibrate for 30min with ultrasonic cleaning, then add 160g of the liquid glue obtained in 1) dropwise under the condition of stirring at 500r / min to obtain a mixed solution, in which the liquid glue The dropping rate is 30 drops / min;

[0033] 3) then filter, dry, and cross a 200-mesh sieve to obtain coated calcium peroxide with a particle diameter≤0.075mm;

[0034] 4) Weigh 20g carbon black, 45g potassium nitrate, 10g lithium borohydride, 24g coat...

Embodiment 2

[0039] A safe ignition powder, the quality of each component in its formula is: 22g of carbon black, 37g of potassium perchlorate, 12g of sodium borohydride, 21g of coated calcium peroxide and 8g of polyazide glycidyl ether.

[0040] A kind of preparation method of safety ignition powder, concrete steps are as follows:

[0041] 1) Dissolve 4g polyethylene in anhydrous acetone, dissolve completely, and form a liquid glue with a mass fraction of 4%;

[0042] 2) Add 50g of calcium peroxide to 300ml of anhydrous dioxane, and after ultrasonically cleaning and vibrating for 30min, add 100g of the liquid glue obtained in 1) dropwise under the condition of stirring at 500r / min to obtain a mixed solution, Wherein the dropping rate of liquid glue is 30 drops / min;

[0043] 3) then filter, dry, and cross a 200-mesh sieve to obtain coated calcium peroxide with a particle diameter≤0.075mm;

[0044] 4) Weigh 22g carbon black, 37g potassium perchlorate, 12g sodium borohydride, 21g coated ca...

Embodiment 3

[0049] A kind of safety ignition powder, the quality of each component in its formula is: 36g carbon black, 32g barium nitrate, 10g sodium borohydride, 15g coated calcium peroxide and 7g 3-azidomethyl butylene oxide .

[0050] A kind of preparation method of safety ignition powder, concrete steps are as follows:

[0051] 1) Dissolve 3g of fluorosilicone rubber in anhydrous dioxane, dissolve completely, and form a liquid glue with a concentration of 3%;

[0052] 2) Add 45g of calcium peroxide to 300ml of anhydrous dioxane, and after ultrasonic cleaning and vibration for 30min, add 90g of the liquid glue obtained in 1) dropwise while stirring at 400r / min to obtain a mixed solution, Wherein the dropping rate of liquid glue is 30 drops / min;

[0053] 3) then filter, dry, and cross a 200-mesh sieve to obtain coated calcium peroxide with a particle diameter≤0.075mm;

[0054] 4) Weigh 36g carbon black, 32g barium nitrate, 10g sodium borohydride, 15g coated calcium peroxide and mix un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com