Low-temperature-freezing magnetic separation method and device for long-chain alkene and long-chain alkane mixture

A technology of alkane mixture and long-chain olefins, which is applied in chemical instruments and methods, purification/separation of hydrocarbons and hydrocarbons, etc., can solve the problems of waxy solids that are not easy to separate solid and liquid, high viscosity, and entrapped impurities in film layers, etc. To achieve the effect of easy solid-liquid separation and speed promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

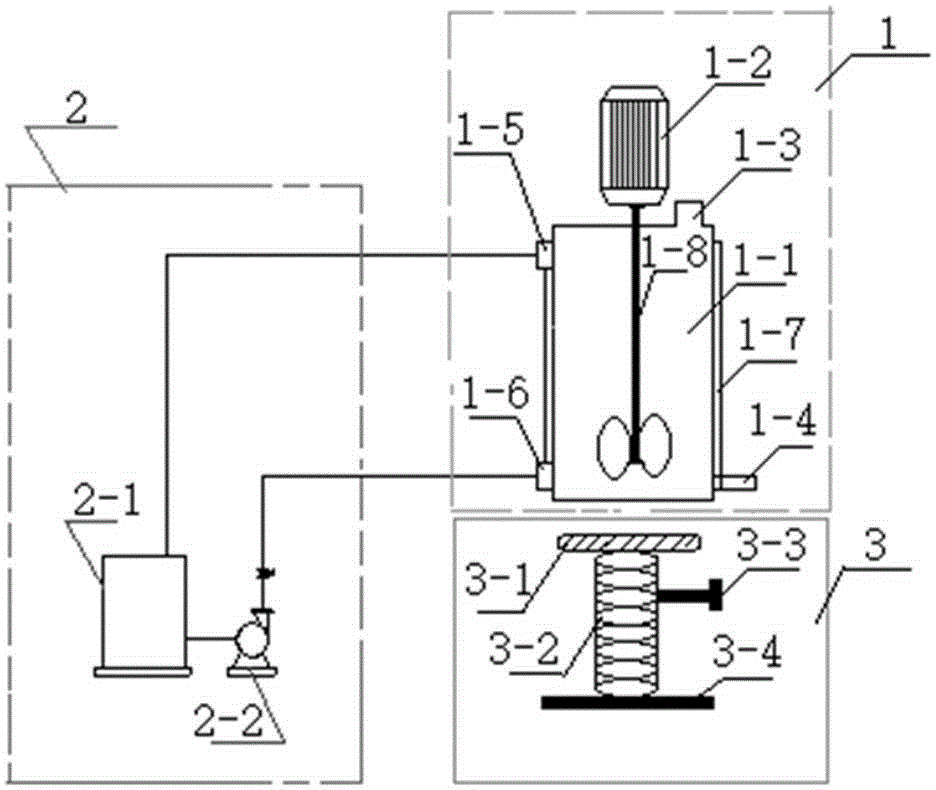

[0023] The structure and application method of the low-temperature freezing and magnetic separation device for long-chain olefin and alkane mixture.

[0024] Such as figure 1 As shown, the device includes a stirring mixer 1, a cooling system 2 and a magnetic separation system 3, wherein the stirring mixer 1 includes a double-layer jacket and a cylindrical cylinder 1-1, and the upper end of the cylinder is provided with a feeding port 1-3, the lower end is provided with a liquid discharge port 1-4, the cylinder is equipped with an agitator 1-8 driven by a motor 1-2, a jacket 1-7 is arranged on the periphery of the cylinder, and the lower end of the jacket 1-7 is provided with an inlet The liquid port 1-6, the upper end of the jacket 1-7 is provided with a liquid outlet 1-5; the cooling system 2 includes a high and low temperature circulating machine 2-1, a circulating pump 2-2, a circulating pump 2-2 and a stirring mixer 1 The lower end of the jacket 1-7 is connected to the li...

Embodiment 2

[0028] Add 10L of dodecene and dodecane mixture with an olefin content of 10% (mass ratio) to the stirring mixer, and then add 1kg of NiFe with a particle size of 500nm 2 o 4Powder, start the motor, stir to make NiFe 2 o 4 The powder is suspended in the oil phase. Set the cooling temperature to -20°C (note: the melting point of dodecane is -9°C, and the melting point of dodecene is -33°C), start the cooling system, and cool down the mixed liquid in the stirring mixer to -20°C Keep warm for 3 hours, stir at 50 rpm, discharge and collect the liquid after magnetic separation, and obtain a carbadodecene product with a content of 90%. Take out the magnetic waxy solid, place it at room temperature to melt to obtain dodecane.

Embodiment 3

[0030] Add 10L olefin content of 50% (mass ratio) tridecene and tridecane mixture to the stirring mixer, and then add 2kg of Fe with a particle size of 500nm 3 o 4 Powder, start the motor, stir to make Fe 3 o 4 The powder is suspended in the oil phase. Set the cooling temperature to -15°C (note: the melting point of tridecane is -5°C, and the melting point of tridecene is -23°C), start the cooling system, and cool down the mixed liquid in the stirring mixer to -15°C Left and right, heat preservation for 5 hours, the stirring speed is 60rpm, after magnetic separation, the liquid is discharged and collected, and the carbadodecene product with a content of 93% is obtained. Take out the magnetic waxy solid, and place it at room temperature to melt to obtain tridecane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap