Quick separation method of lotus seed oligosaccharide monomers with prebiotic effect

A separation method and technology of oligosaccharides, applied in the direction of oligosaccharides, chemical instruments and methods, sugar derivatives, etc., to achieve the effects of easy evaporation recovery, avoiding environmental pollution, and increasing separation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

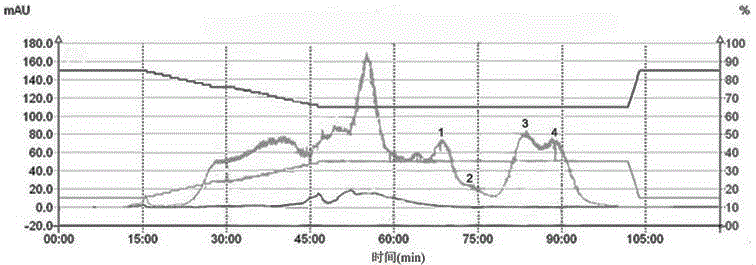

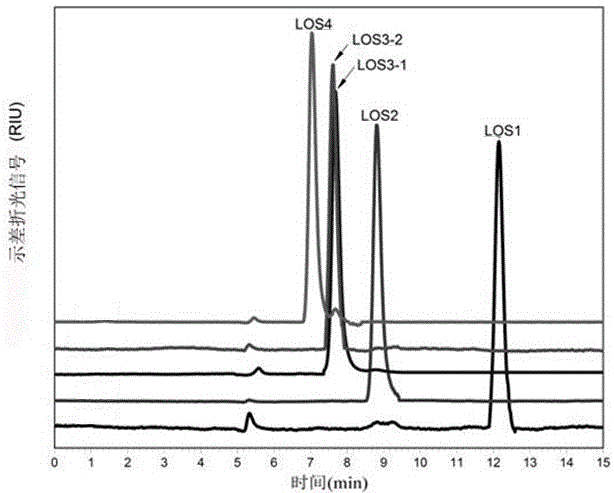

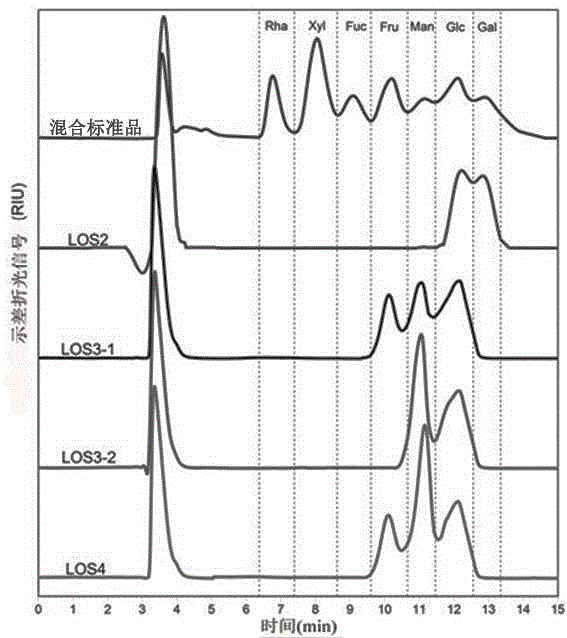

Method used

Image

Examples

Embodiment 1

[0045] A method for rapidly separating lotus seed oligosaccharide monomers with a prebiotic effect, which specifically comprises the following steps:

[0046] 1) Material selection and drying: select fresh lotus seeds with full granules and no damage, screen and remove the core, put them in a blast drying oven, and dry them at 40°C until the moisture content is 4%;

[0047] 2) Crushing and sieving: crush the dried lotus seeds in step 1, and pass through a 40-mesh sieve;

[0048] 3) Compounding with water: take the lotus seed powder obtained in step 2), add deionized water and mix well according to the material-to-liquid ratio of 1:5 for compounding;

[0049] 4) Water-washed starch: Pass the compounding solution obtained in step 3) through a 100-mesh sieve, and wash the filter residue with deionized water 4 times the weight of lotus seeds. After combining the filtrate, place it at 4°C for 8 hours, and centrifuge to remove the precipitate. The resulting supernatant is combined ...

Embodiment 2

[0059] A method for rapidly separating lotus seed oligosaccharide monomers with a prebiotic effect, which specifically comprises the following steps:

[0060] 1) Material selection and drying: select fresh lotus seeds with full granules and no damage, screen and remove the core, put them in a blast drying oven, and dry them at 45°C until the moisture content is 5.5%;

[0061] 2) Crushing and sieving: crush the dried lotus seeds in step 1, and pass through a 40-mesh sieve;

[0062] 3) Compounding with water: take the lotus seed powder obtained in step 2), add deionized water and mix well according to the material-to-liquid ratio of 1:5 for compounding;

[0063] 4) Water-washed starch: Pass the compounding solution obtained in step 3) through a 100-mesh sieve, and wash the filter residue with deionized water 5 times the weight of lotus seeds. After combining the filtrate, place it at 4°C for 8 hours, and centrifuge to remove the precipitate. The resulting supernatant is combine...

Embodiment 3

[0073] A method for rapidly separating lotus seed oligosaccharide monomers with a prebiotic effect, which specifically comprises the following steps:

[0074] 1) Material selection and drying: select fresh lotus seeds with full granules and no damage, screen and remove the core, put them in a blast drying oven, and dry them at 50°C until the moisture content is 7%;

[0075] 2) Crushing and sieving: crush the dried lotus seeds in step 1, and pass through a 40-mesh sieve;

[0076]3) Compounding with water: take the lotus seed powder obtained in step 2), add deionized water and mix well according to the material-to-liquid ratio of 1:5 for compounding;

[0077] 4) Water-washed starch: Pass the compounding liquid obtained in step 3) through a 100-mesh sieve, and wash the filter residue with deionized water 6 times the weight of lotus seeds. After combining the filtrate, place it at 4°C for 8 hours, and centrifuge to remove the precipitate. The resulting supernatant is combined wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com