Visible-near-infrared ultra-broadband absorber and preparation method

An ultra-broadband and absorber technology, which is applied to instruments, instrument parts, shielding, etc., can solve problems such as low absorption rate and complicated preparation process, and achieve the effects of shortened production cycle, good absorption performance, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

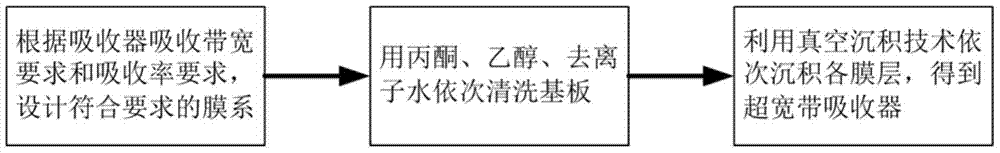

[0035] A preparation method of an ultra-broadband absorber in the visible-near-infrared band, comprising the following steps, such as figure 2 Shown:

[0036] 1) According to the required absorber bandwidth requirements and absorption rate requirements, by optimizing the thickness of each layer of film, design a film system that meets the requirements;

[0037] 2) put the substrate into the acetone solution for 8 minutes, then clean the substrate with ethanol; then put the substrate (substrate) into the ethanol solution for 8 minutes, then clean the substrate with deionized water; finally clean the substrate Put it in deionized water for 8 minutes, and then wash the substrate again with deionized water;

[0038] 3) Vacuum coating technology is used to deposit each film layer in sequence to obtain an ultra-broadband absorber in the visible-near infrared band;

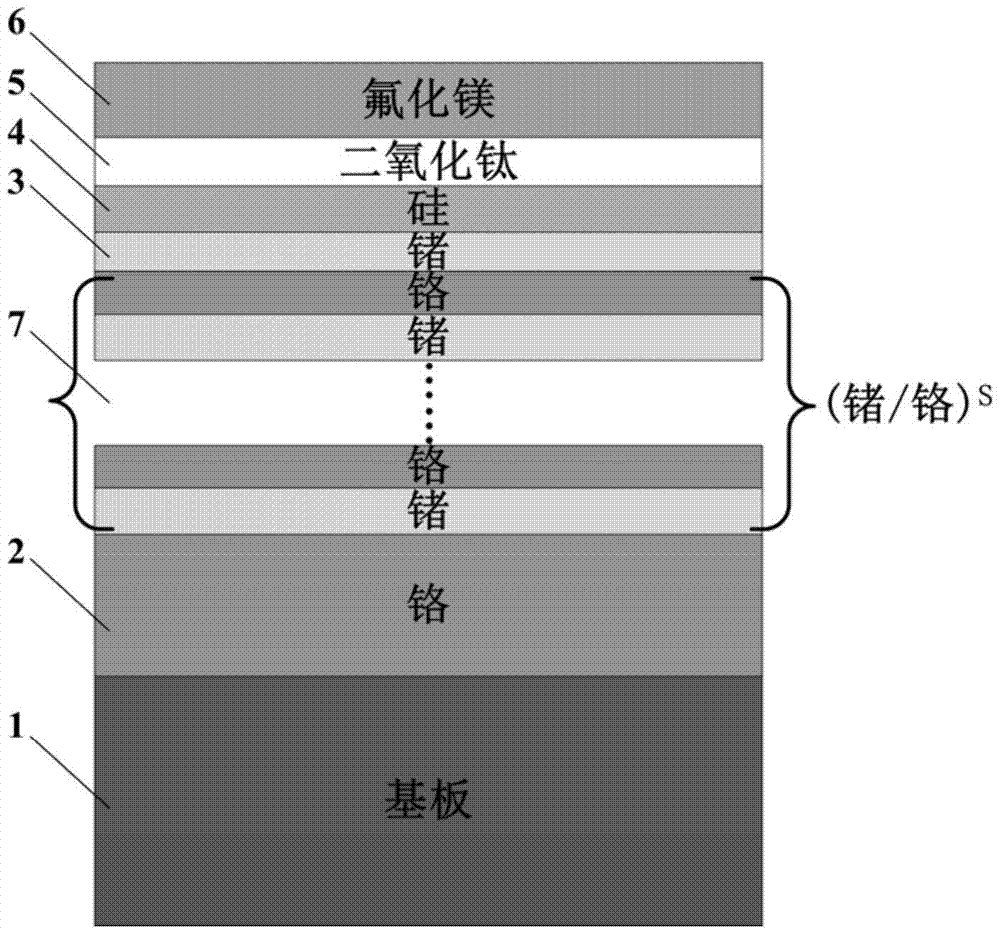

[0039] The ultra-broadband absorption of the ultra-broadband absorber in the visible-near-infrared band of the pres...

Embodiment 1

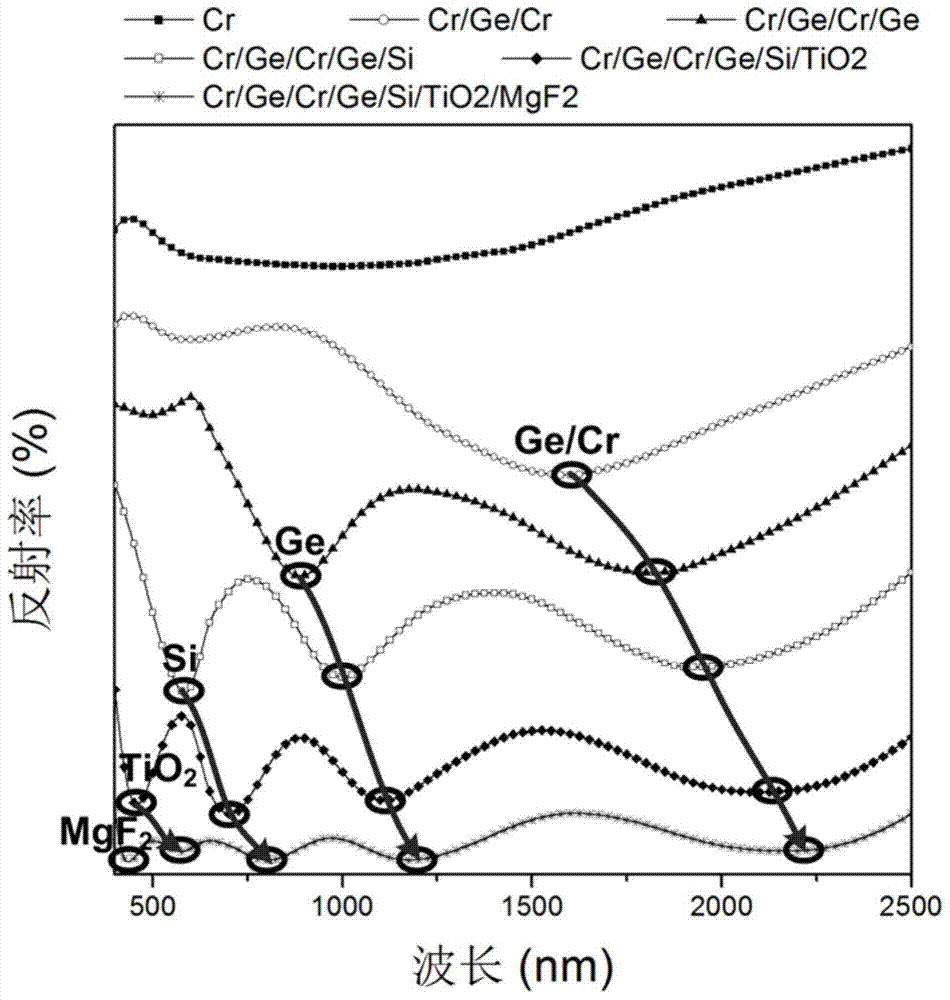

[0041] Embodiment 1: Visible-near-infrared band ultra-broadband absorber, the expected absorption bandwidth is 400nm-2500nm, and the absorption rate of each wavelength is more than 90%. The absorption spectrum of the absorber sample prepared by the present invention is as follows Figure 4 As shown, the average absorption rate is above 96.82%, and the corresponding structure is S=1, 7 layers of Cr / Ge / Cr / Ge / Si / TiO 2 / MgF 2 Thin-film structure, the corresponding substrate material is silicon wafer, and the thickness of each film layer is 200nm (chromium), 52nm (germanium), 21nm (chromium), 33nm (germanium), 34nm (silicon) from bottom to top. , 57nm (titanium dioxide), 111nm (magnesium fluoride).

Embodiment 2

[0042] Embodiment 2: Visible-near-infrared band ultra-broadband absorber, the expected absorption bandwidth is 400nm-3000nm, and the absorption rate of each wavelength is more than 90%. The absorption spectrum of the film system designed by the present invention is as follows Figure 5 As shown, the average absorption rate is above 94.9%, and the corresponding structure is S=2, 9 layers of Cr / Ge / Cr / Ge / Cr / Ge / Si / TiO 2 / MgF 2 Thin-film structure, the corresponding substrate material is silicon wafer, and the thickness of each film layer is 200nm (chromium), 72nm (germanium), 22nm (chromium), 55nm (germanium), 15nm (chromium) from bottom to top. , 36nm (germanium), 37nm (silicon), 57nm (titanium dioxide), 110nm (magnesium fluoride).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com