Bonding copper wire for fine-pitch IC packaging and manufacturing method thereof

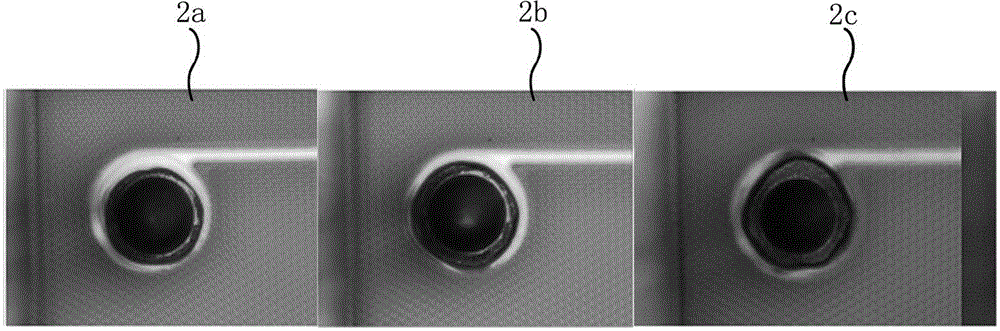

A technology of bonding copper wire and fine pitch, which is applied in the field of bonding wire, can solve problems such as out-of-round deformed balls, short-circuited deformed balls, and increased hardness of copper wires, achieving high roundness, good symmetry, and product reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The manufacturing method of the bonding copper wire used for fine-pitch IC packaging in this embodiment includes the following steps:

[0028] (1) Melting and casting: the copper with a purity of 4N and a main body oxygen content of 4ppm (weight) is subjected to vacuum smelting and directional continuous drawing process to obtain a wire rod with a diameter of 8 millimeters (mm);

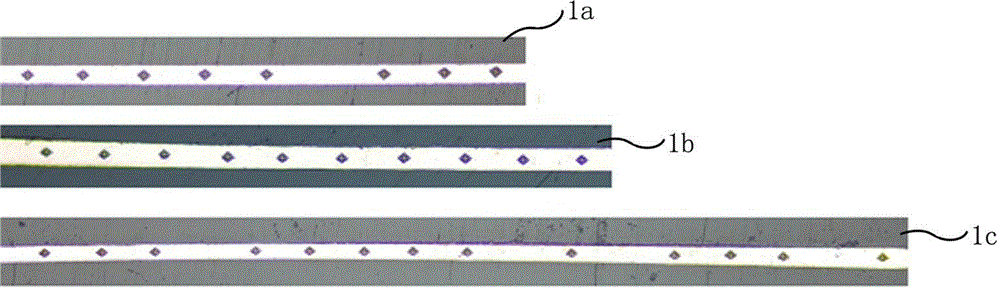

[0029] (2) Wire drawing: the wire rod obtained in step (1) is drawn (the whole wire drawing process includes multiple wire drawing operations, and undergoes stages such as rough drawing, small drawing, fine drawing, and micro drawing) to obtain a wire with a diameter of 23 microns (um). Bonding copper wire;

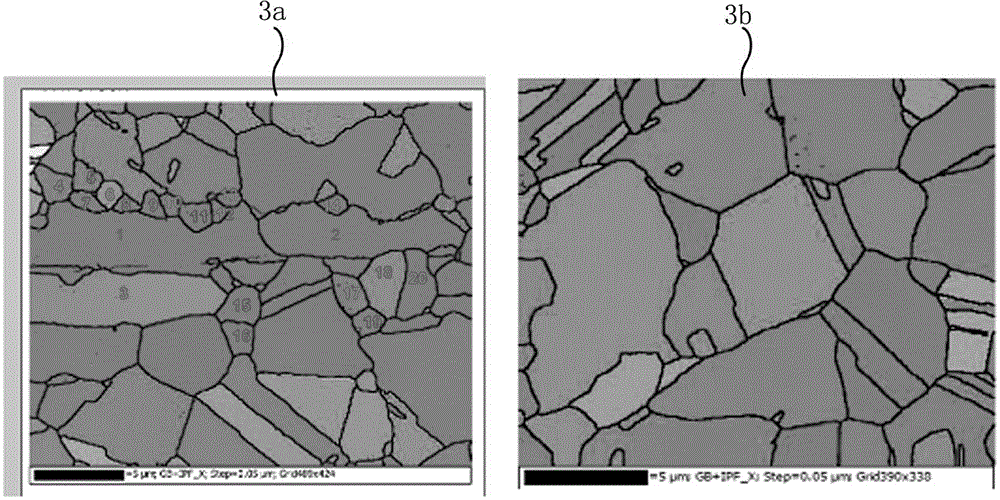

[0030] During the wire drawing process, an intermediate annealing is carried out on the wire. The intermediate annealing is carried out when the wire drawing reaches a diameter of 0.0556 mm (mm). During the annealing process, N2 (nitrogen) is used as the annealing atmosphere. The effectiv...

Embodiment 2

[0034] The manufacturing method of the bonding copper wire used for fine-pitch IC packaging in this embodiment includes the following steps:

[0035] (1) Melting and casting: the copper with a purity of 4N and a main oxygen content of 3ppm (weight) is subjected to vacuum melting and directional continuous drawing process to obtain a wire rod with a diameter of 8 millimeters (mm);

[0036] (2) Wire drawing: the wire rod obtained in step (1) is drawn (the whole wire drawing process includes multiple wire drawing operations, and undergoes stages such as rough drawing, small drawing, fine drawing, and micro drawing) to obtain a wire with a diameter of 23 microns (um). Bonding copper wire;

[0037] During the wire drawing process, an intermediate annealing is carried out on the wire. The intermediate annealing is carried out when the wire is drawn to a diameter of 0.0384 mm (mm). During the annealing process, N2 (nitrogen) is used as the annealing atmosphere. The effective length o...

Embodiment 3

[0041] The manufacturing method of the bonding copper wire used for fine-pitch IC packaging in this embodiment includes the following steps:

[0042] (1) Melting and casting: the copper with a purity of 4N and a main oxygen content of 3ppm (weight) is subjected to vacuum melting and directional continuous drawing process to obtain a wire rod with a diameter of 8 millimeters (mm);

[0043] (2) Wire drawing: the wire rod obtained in step (1) is drawn (the whole wire drawing process includes multiple wire drawing operations, and undergoes stages such as rough drawing, small drawing, fine drawing, and micro drawing) to obtain a wire with a diameter of 23 microns (um). Bonding copper wire;

[0044] During the wire drawing process, an intermediate annealing is carried out on the wire. The intermediate annealing is carried out when the wire is drawn to a diameter of 0.0893 mm (mm). During the annealing process, N2 (nitrogen) is used as the annealing atmosphere. The effective length o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com