Preparation method for solid drink

A solid beverage and raw material technology, which is applied in the field of food and health care products, can solve problems such as poor taste, gastrointestinal irritation, and low product quality, and achieve the effects of avoiding the loss of aroma and flavor, avoiding volatilization loss, and shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

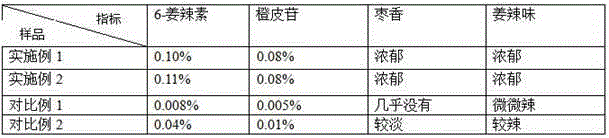

Examples

Embodiment 1

[0033] Raw material ratio:

[0034] 3 parts of ginger, 3 parts of red dates, 0.5 part of ginseng, 0.5 part of tangerine peel, 2 parts of fructose, 1 part of maltodextrin, and 0.01 part of steviol glycoside. The preparation process includes the following steps:

[0035] a) Take ginger, wash, crush, squeeze the juice, and store the ginger juice in a clean container for later use; wash the red dates, dry them at 80°C, stir-fry them with a slow fire (120-140°C) for 10 minutes, and crush them into coarse powder (all pass through a 20-mesh sieve); ginseng, washed, dried, and pulverized into a coarse powder (all passed through a 20-mesh sieve); tangerine peel, selected to remove impurities, washed, dried at 60°C, and pulverized into a coarse powder (all passed through a 20-mesh sieve);

[0036] b) Take the ginger slag after squeezing the juice, add 10 times the 70% ethanol to ultrasonic extraction for 40 minutes, the ultrasonic frequency is 30Hz, the temperature is 45°C, and the stir...

Embodiment 2

[0041] Raw material ratio:

[0042] 6 parts of ginger, 6 parts of red dates, 1 part of ginseng, 0.5 part of tangerine peel, 0.04 part of steviol glycoside, 1 part of fructose, and 2 parts of maltodextrin. The preparation process includes the following steps:

[0043] a) Take ginger, wash, crush, squeeze the juice, and store the ginger juice in a clean container for later use; wash the red dates, dry them at 80°C, stir-fry them with a slow fire (120-140°C) for 10 minutes, and crush them into coarse powder (all pass through a 20-mesh sieve); ginseng, washed, dried, and pulverized into a coarse powder (all passed through a 20-mesh sieve); tangerine peel, selected to remove impurities, washed, dried at 60°C, and pulverized into a coarse powder (all passed through a 20-mesh sieve);

[0044] b) Take the ginger residue after squeezing the juice, add 15 times of 95% ethanol to ultrasonic extraction for 30 minutes, ultrasonic frequency 40Hz, temperature 60℃, stirring speed 100r / min , ...

Embodiment 3

[0049] Raw material ratio:

[0050] 5 parts of ginger, 5 parts of red dates, 1 part of ginseng, 0.5 part of tangerine peel, 0.03 part of steviol glycoside, 1.5 parts of fructose, and 3 parts of maltodextrin. The preparation process includes the following steps:

[0051] a) Take ginger, wash, crush, squeeze the juice, and store the ginger juice in a clean container for later use; wash the red dates, dry them at 80°C, stir-fry them with a slow fire (120-140°C) for 15 minutes, and crush them into coarse powder (all pass through a 20-mesh sieve); ginseng, washed, dried, and pulverized into a coarse powder (all passed through a 20-mesh sieve); tangerine peel, selected to remove impurities, washed, dried at 60°C, and pulverized into a coarse powder (all passed through a 20-mesh sieve);

[0052] b) Take the ginger residue after squeezing the juice, add 15 times of 85% ethanol to ultrasonic extraction for 1 hour, ultrasonic frequency 20Hz, temperature 50℃, stirring speed 200r / min , f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com