Preparation method of adriamycin polymer drug

A doxorubicin and polymer technology, applied in the field of polymer chemistry and polymers, can solve the problems of reduced water solubility of drug molecules, high synthesis cost, poor biocompatibility, etc., to reduce toxic side effects and improve biocompatibility Good, heavy load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

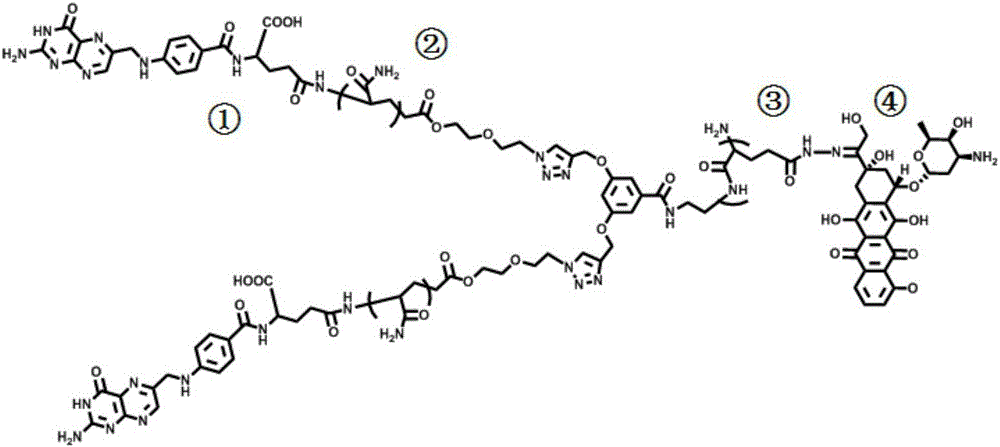

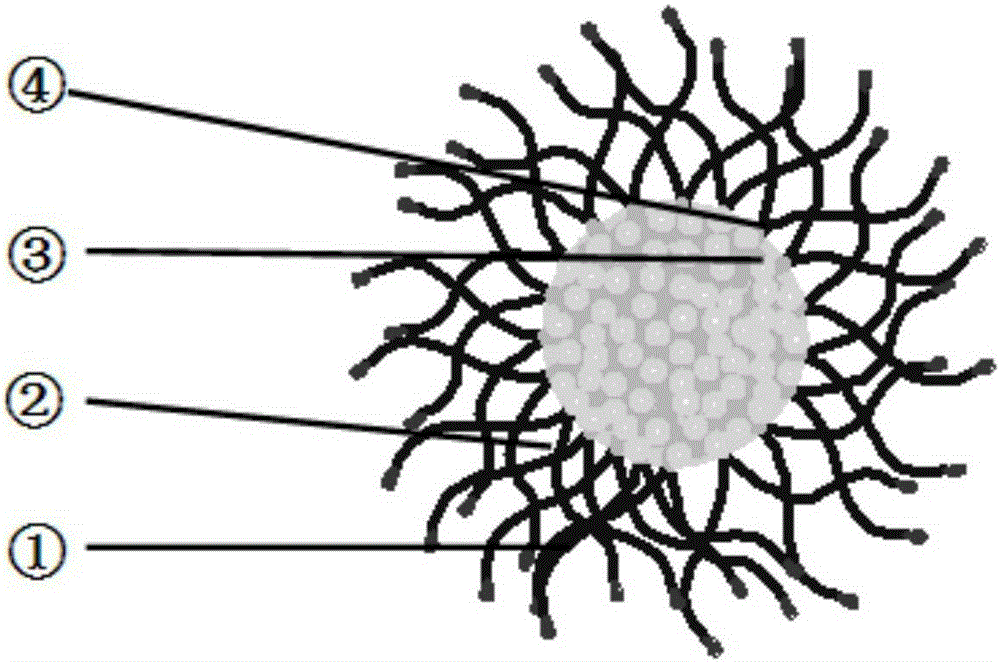

Method used

Image

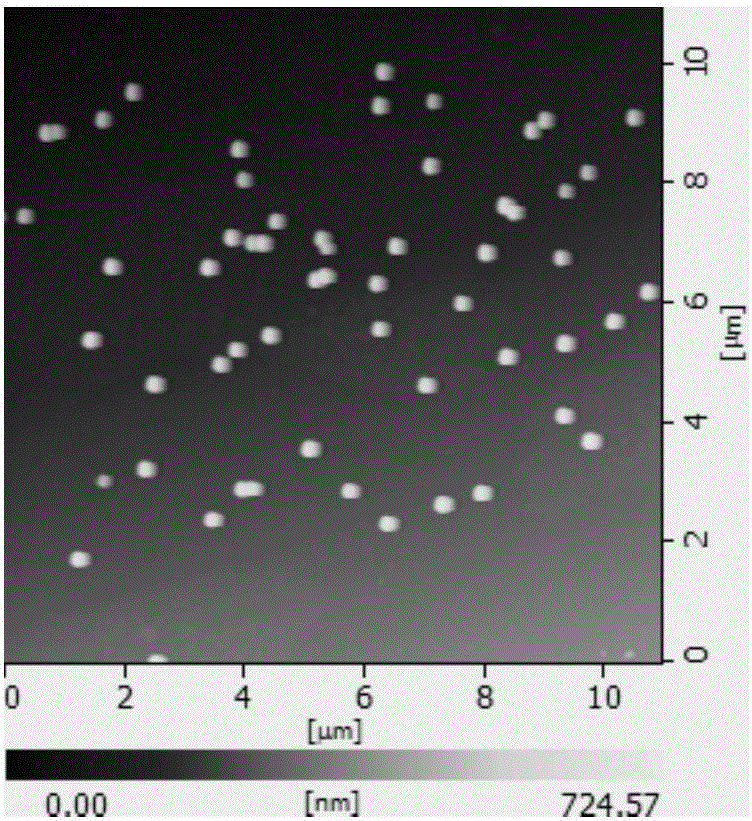

Examples

Embodiment 1

[0044] ①Prepare azide small molecule initiator

[0045] Step 1: Dissolve 5mL of 2-chloroethoxyethanol in 25mL of methyl ethyl ketone, add 4.5g of NaN to the solution 3 , 2.5gBu 4 NI, 10 mg of dicyclohexane-18-crown-6, heat the mixture to boiling and stir for 24 hours. The mixture was filtered and the precipitate was thoroughly rinsed with acetone. The resulting mixed solution is the crude product. After concentrating the mixed solution, o C is distilled to obtain a pure product. The resulting 2-azidoethoxyethanol 1 HNMR(CDCl 3 ): δ 3.70(t,2H,C H 2 OH), 3.65(t, 2 H,HOCH 2 C H 2 O),3.56(t,2H,N 3 CH 2 C H 2 O), 3.37(t, 2H, C H 2 N 3 ), and2.56(s,1H,OH).

[0046] Step 2: Dissolve 2 g of 2-azidoethoxyethanol and 5.09 g of α-chloro acid chloride prepared in step 1 in 30 mL of dichloromethane, transfer the reaction system to the ice field, and transfer 6.8 g of dicyclohexyl The carbodiimide was slowly added to the reaction vessel and stirred. 0.4 g of dimethylaminopyridine was dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com