Preparation method for magnetic carbon microsphere surface cephalexin molecular imprinted adsorbent material

A technique for cephalexin molecules and imprinted adsorption, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of magnetic carbon microspheres

[0022] Select walnut shells and dry them at a temperature of 115° C. for 18 hours, and crush the dried walnut shells to a particle size of about 2.0-4.0 mm to obtain raw material particles. Pass the above-mentioned walnut shell particles through 3.0mol / L hydrochloric acid, reflux at 70°C for 12 hours, wash with distilled water several times to neutralize, and dry at 60°C until constant weight to obtain acid-activated walnut shell particles.

[0023] The acid-activated walnut shell particles prepared above were mixed with FeCl 3 .6H 2 O, sodium acetate according to the acid activation of walnut shells: FeCl 3 .6H 2 O: Sodium acetate is dissolved in ethylene glycol at a ratio of 1.0: 0.5: 2.0 (g / g / g), and the amount of ethylene glycol is activated according to the acid activated walnut shell: ethylene glycol=1.0: 100 (g / ml ), ultrasonically stirred for 30min, mixed evenly, then added polyethylene glycol to the above-me...

Embodiment 2

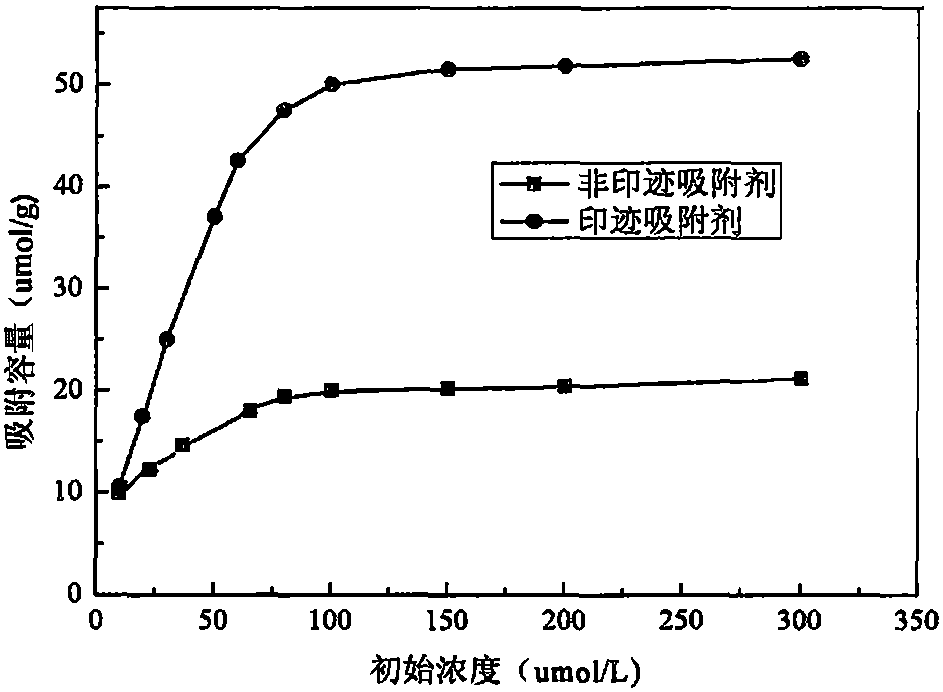

[0032] Take 25ml of cephalexin solutions with initial concentrations of 5, 10, 20, 30, 50, 60, 80, 100, 150, 200, and 300 μmol / L and add them to the centrifuge tube, and add 10 mg of magnetic carbon microsphere surface imprinted adsorbent and non-imprinted adsorbent, put the test solution in a water bath at 25°C and let it stand for 24.0h, then separate and collect the supernatant with a Nd-Fe-B permanent magnet, and measure the molecular concentration of unadsorbed cephalexin with a UV-visible spectrophotometer , to calculate the adsorption capacity, figure 1 The results show that the saturated adsorption capacity of the imprinted adsorbent is 52.35umol / g higher than that of the non-imprinted adsorbent 19.36umol / g, which proves that the imprinted adsorbent has a large number of imprinted holes and shows a good imprinting effect.

Embodiment 3

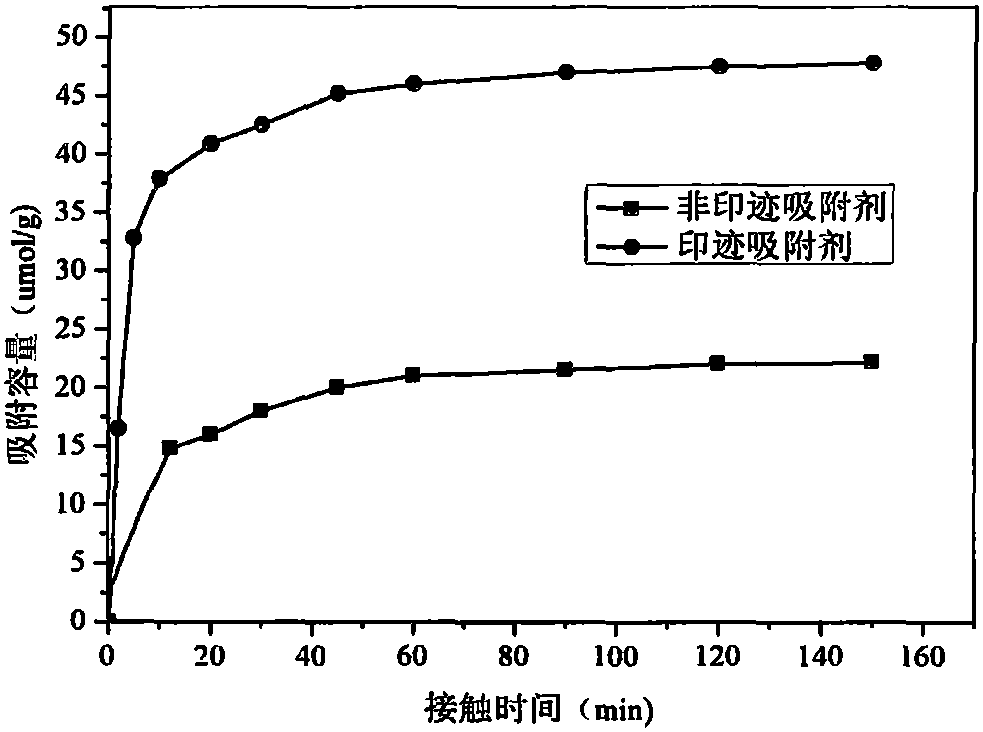

[0034] Take 25ml of cephalexin solution with an initial concentration of 150 μmol / L and add it to a centrifuge tube, add 10 mg of magnetic carbon microsphere surface imprinted adsorbent and non-imprinted adsorbent, and place the test solution in a water bath at 25°C for 2 and 5 minutes respectively. , 10, 20, 30, 45, 60, 90, 120 and 150min, after standing still, the supernatant was separated and collected by Nd-Fe-B permanent magnet, and the molecular concentration of unadsorbed cephalexin was measured by UV-visible spectrophotometer Determination, calculate the adsorption capacity, from figure 2 It can be seen that at the beginning, with the increase of adsorption time, the adsorption capacity increased rapidly, and the adsorption reached equilibrium after 30 min. In the whole adsorption time range, the adsorption capacity of cephalexin molecules by the imprinted adsorbent on the surface of magnetic carbon microspheres was greater than that of the non-imprinted adsorbent. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com