A kind of zif-8@mcm-41 molecular sieve and preparation method thereof

A technology of MCM-41 and ZIF-8, which is applied in the direction of chemical instruments and methods, other chemical processes, physical/chemical process catalysts, etc., can solve the problems of easy decomposition, limited application, and the inability of zeolite imidazolate framework materials to withstand temperature, etc. Achieve the effect of good porosity, low density and high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

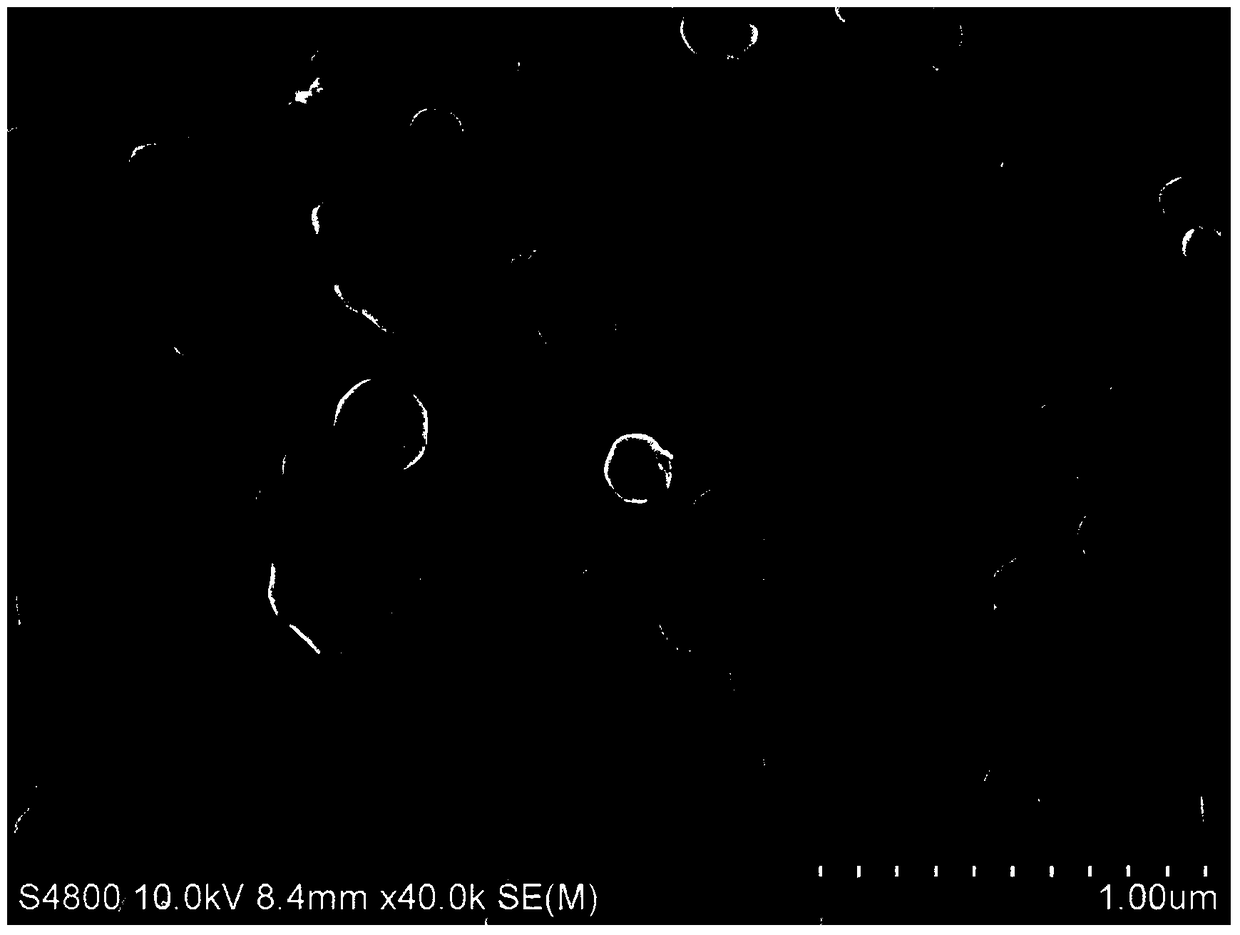

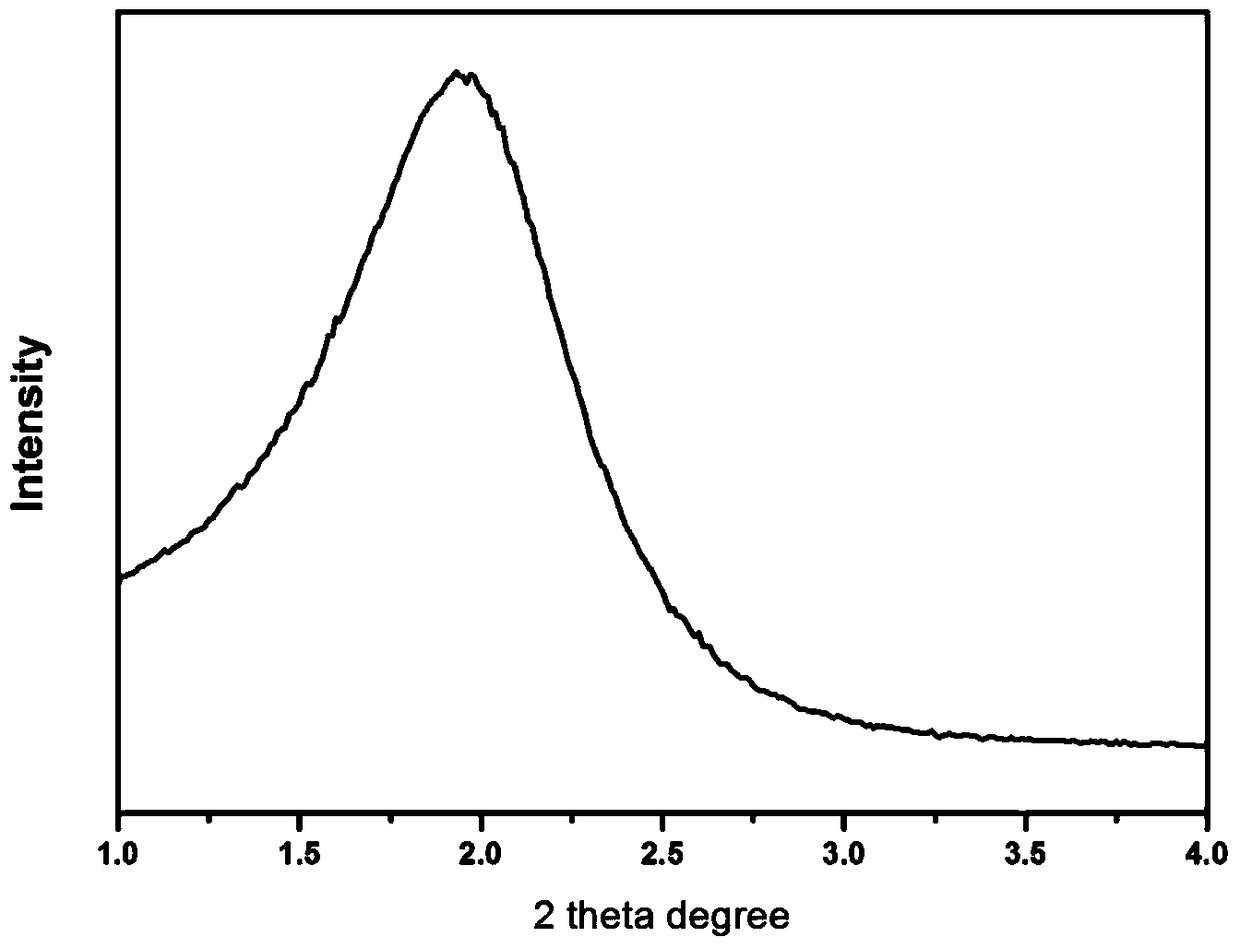

[0025] Dissolve 0.585g of zinc nitrate hexahydrate in 4g of deionized water to make a zinc nitrate solution, dissolve 11.35g of 2-methylimidazole in 40g of deionized water to make a 2-methylimidazole solution, mix the two and then stir for 0.5 h, centrifuged, washed and dried to obtain white powder ZIF-8 particles. Such as Figure 5 Shown is the scanning electron microscope image of the ZIF-8 particles obtained in this example. It can be seen from the figure that the particle size of the ZIF-8 particles is 50-70 nm, and the particle size is uniform.

[0026] Mix 2 g of the obtained ZIF-8 granules with 0.125 g of surfactant CTAB and 20 g of deionized water, then add 0.45 mL of NaOH solution with a concentration of 2 mol / L to adjust the pH to 9, stir and heat at 80 °C for 1 h, slowly dropwise Add 0.625mL tetraethyl orthosilicate and continue the reaction for 8h. After the reaction, let the reaction solution stand still, filter, wash, and dry to obtain a white powder, then heat ...

Embodiment 2

[0029] Dissolve 0.585g of zinc nitrate hexahydrate in 4g of deionized water to make a zinc nitrate solution, dissolve 11.35g of 2-methylimidazole in 40g of deionized water to make a 2-methylimidazole solution, mix the two and then stir for 0.5 h, centrifuged, washed and dried to obtain white powder ZIF-8 particles. Mix 2 g of the obtained ZIF-8 particles with 0.25 g of surfactant CTAB and 80 g of deionized water, then add 0.9 mL of NaOH solution with a concentration of 2 mol / L to adjust the pH value to 10, stir and heat at 80 ° C for 1 h, slowly dropwise Add 0.625mL tetraethyl orthosilicate and continue the reaction for 8h. After the reaction, let the reaction solution stand still, filter, wash, and dry to obtain a white powder, then heat the white powder to reflux in 50mL of ethanol to remove the surfactant CTAB, and finally Stand still, wash and dry to obtain white powder ZIF-8@MCM-41 molecular sieve.

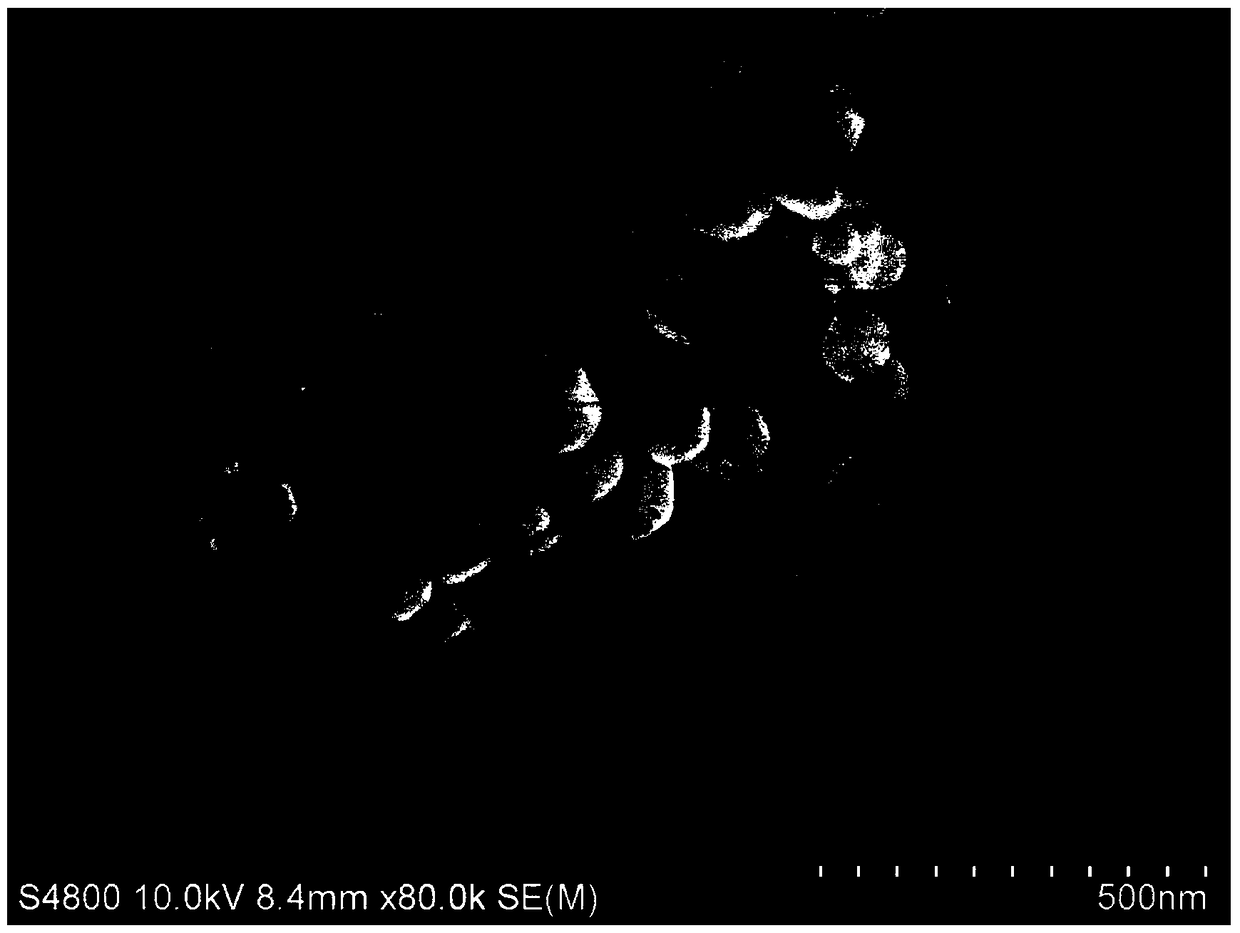

[0030] figure 2 It is a scanning electron microscope image of the pro...

Embodiment 3

[0032] Dissolve 0.585g of zinc nitrate hexahydrate in 4g of deionized water to make a zinc nitrate solution, dissolve 11.35g of 2-methylimidazole in 40g of deionized water to make a 2-methylimidazole solution, mix the two and then stir for 0.5 h, centrifuged, washed and dried to obtain white powder ZIF-8 particles. Mix 2 g of the obtained ZIF-8 granules with 0.5 g of surfactant CTAB and 200 g of deionized water, then add 1.8 mL of NaOH solution with a concentration of 2 mol / L to adjust the pH to 10, stir and heat at 80 ° C for 1 h, slowly dropwise Add 0.625mL tetraethyl orthosilicate and continue the reaction for 8h. After the reaction, let the reaction solution stand still, filter, wash, and dry to obtain a white powder, then heat the white powder to reflux in 50mL of ethanol to remove the surfactant CTAB, and finally Stand still, wash and dry to obtain white powder ZIF-8@MCM-41 molecular sieve.

[0033] Figure 4 It is a scanning electron microscope picture of the product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com