Laser-InFocus electric arc double-face symmetric composite welding method

An infocus and hybrid welding technology, which is applied in the field of laser-InFocus arc double-sided symmetrical composite welding, can solve the problems of high laser power requirements and high costs, and achieve the effects of improving welding quality, reducing equipment costs, and increasing the aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: a kind of laser-InFocus electric arc double-sided symmetric composite welding method of the present embodiment, it is carried out according to the following steps:

[0026] Step 1: Process the workpiece to be welded into an I-shaped or Y-shaped groove, and grind and clean the processed groove and the surfaces on both sides, and fix the polished and cleaned workpiece to be welded on the welding fixture ;

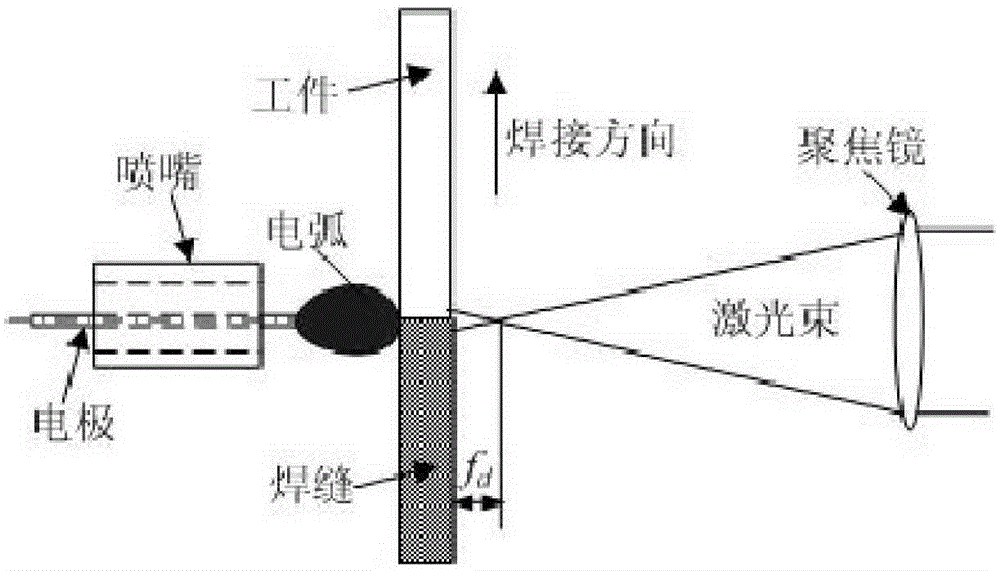

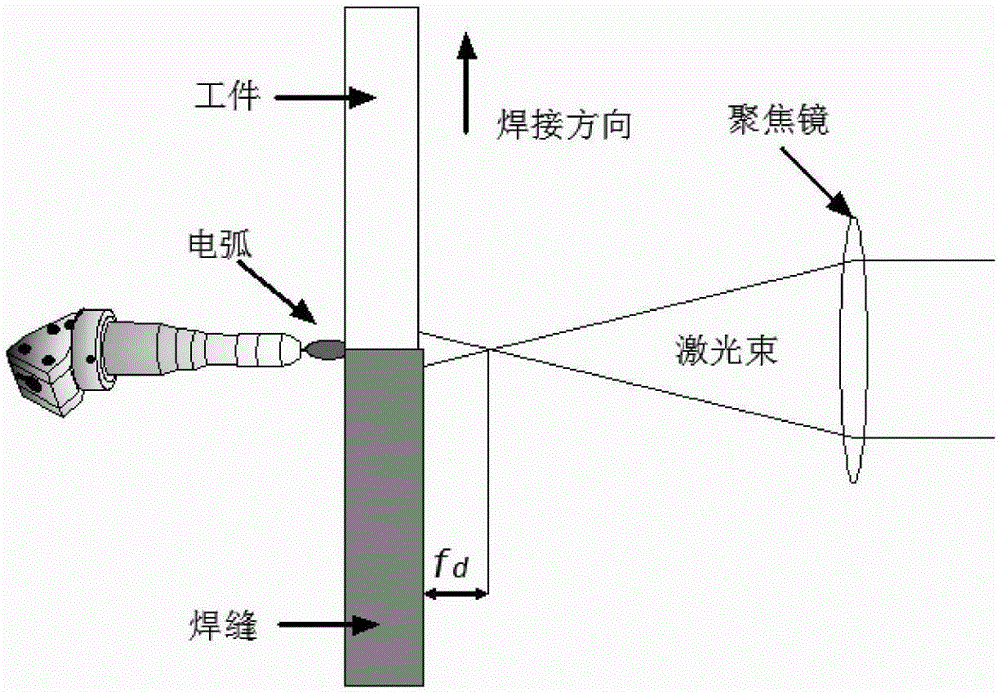

[0027] Step 2: keep the laser beam and the InFocus arc welding torch on the same axis during the welding process, and the angle between the axis and the workpiece is 85° to 95°;

[0028] Step 3: Set the welding process parameters: the spot diameter is 0.1-0.5mm, the defocus is ﹣3-﹢3mm, the laser power is 500-5000W, the InFocus arc current is 50-1000A, and the welding speed is 50-900mm / min , both the laser and InFocus shielding gas use Ar gas, the laser shielding gas flow rate is 10-30L / min, and the InFocus shielding gas flow rate is 10-25L / min...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the hybrid welding is to use the laser and the InFocus electric arc to be welded in parallel with the direction of the welding seam, and the welding conditions are: the welding torch and the laser head are in the The same plane, and the plane is perpendicular to the direction of the weld, the laser head is located on the side of the workpiece with a relatively high melting point among the workpieces to be welded, and the focus of the laser beam is focused on the edge of the side of the workpiece with a relatively high melting point among the butt welded workpieces to be welded, The angle between the laser beam and the vertical direction is 5-30°; the welding torch of the InFocus arc is located on the side of the workpiece with a relatively low melting point among the workpieces to be welded, and the welding torch is placed at the center of the weld gap. Others are the same as ...

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the angle between the axis and the workpiece in step 2 is 90°-95°. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com