Preparation method of dihydrate sodium dichloroisocyanate

The technology of sodium dichloroisocyanurate and sodium dichloroisocyanurate is applied in the field of preparation of disinfectants, can solve the problems of poor operating environment, difficult operation, low volume production capacity, etc., and achieves easy operation, easy control, and production. The effect of continuous process and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

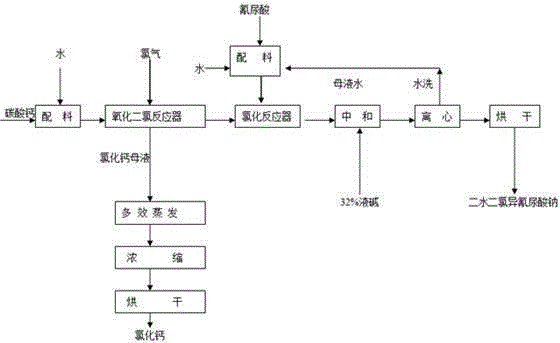

Image

Examples

Embodiment 1

[0027] A kind of preparation method of sodium dichloroisocyanate dihydrate, is characterized in that: comprise the steps:

[0028] (1) Preparation of calcium carbonate suspension:

[0029] In a 5000L stirring enamel batching kettle, according to the weight ratio of 99% calcium carbonate and water 1:4, 1000kg of 99% calcium carbonate and 4000kg of water are made into calcium carbonate suspension;

[0030] (2) Preparation of intermediate product dichloride oxide:

[0031] Send the calcium carbonate suspension obtained in step (1) into the chlorine dioxide pipeline reactor, which is equipped with a high-pressure circulation pump to provide a reaction pressure of 0.6MPa, and the chlorine dioxide pipeline reactor is also equipped with a circulation tank , the circulation tank is equipped with a cooling device, the reaction temperature is controlled at 16°C, and 99% chlorine gas is fed through the jet pump at 190L / h to obtain the product oxidized dichlorine gas and a calcium chlori...

Embodiment 2

[0039] A kind of preparation method of sodium dichloroisocyanate dihydrate, is characterized in that: comprise the steps:

[0040] (1) Preparation of calcium carbonate suspension:

[0041] In a 5000L stirring enamel batching kettle, according to the weight ratio of 99% calcium carbonate and water 1:5, 800kg of 99% calcium carbonate and 4000kg of water are made into calcium carbonate suspension;

[0042] (2) Preparation of intermediate product dichloride oxide:

[0043] Send the calcium carbonate suspension obtained in step (1) into the chlorine dioxide pipeline reactor, which is equipped with a high-pressure circulation pump to provide a reaction pressure of 0.65MPa, and the chlorine dioxide pipeline reactor is also equipped with a circulation tank , the circulation tank is equipped with a cooling device, the reaction temperature is controlled at 18°C, and 99% chlorine gas is fed through a jet pump at 190L / h to obtain the product oxidized dichlorine gas and a calcium chloride...

Embodiment 3

[0051] A kind of preparation method of sodium dichloroisocyanate dihydrate, is characterized in that: comprise the steps:

[0052] (1) Preparation of calcium carbonate suspension:

[0053] In a 5000L stirring enamel batching kettle, according to the weight ratio of 99% calcium carbonate and water 1:4, 1000kg of 99% calcium carbonate and 4000kg of water are made into calcium carbonate suspension;

[0054] (2) Preparation of intermediate product dichloride oxide:

[0055] Send the calcium carbonate suspension obtained in step (1) into the chlorine dioxide pipeline reactor, which is equipped with a high-pressure circulation pump to provide a reaction pressure of 0.6MPa, and the chlorine dioxide pipeline reactor is also equipped with a circulation tank , the circulation tank is equipped with a cooling device, the reaction temperature is controlled at 20°C, and 99% chlorine gas is fed through the jet pump at 190L / h to obtain the product oxidized dichlorine gas and a calcium chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com