Modified cellulose nanometer crystal and preparation method thereof

A technology of nanocrystals and cellulose, applied in the field of modified cellulose nanocrystals and its preparation, can solve the problems of poor thermal stability and poor compatibility, and achieve the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

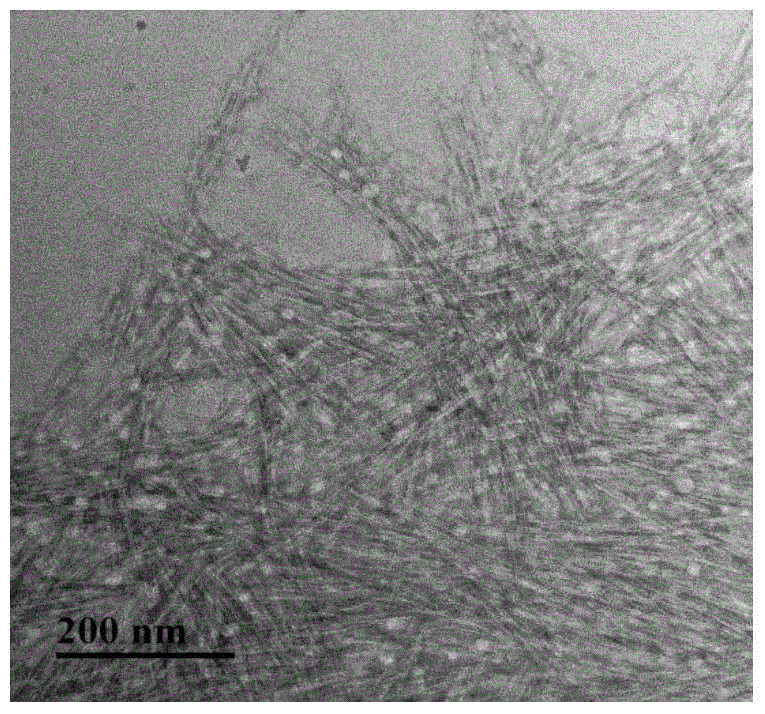

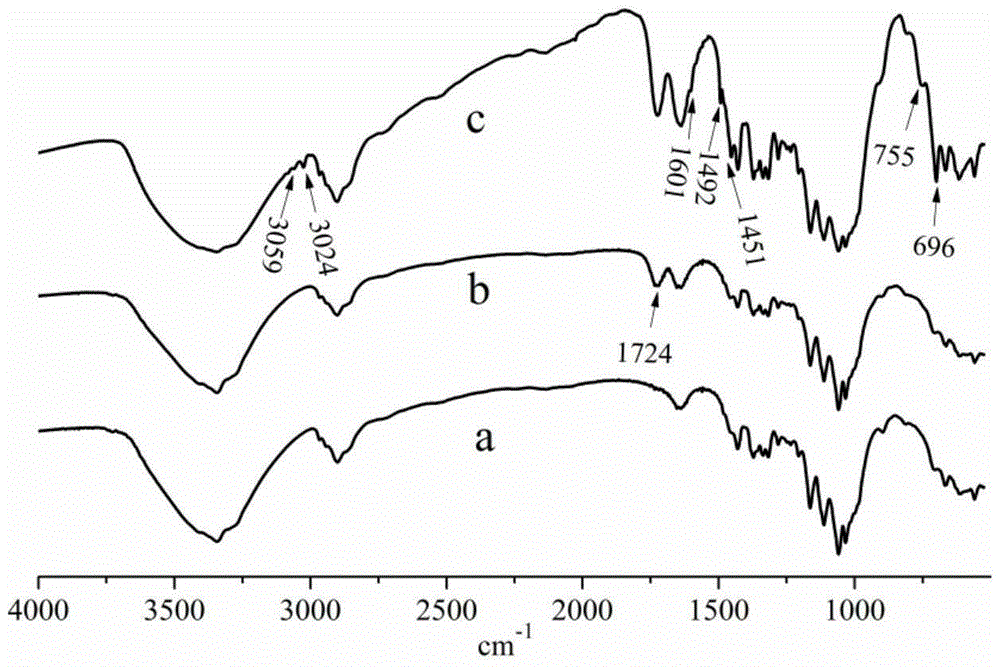

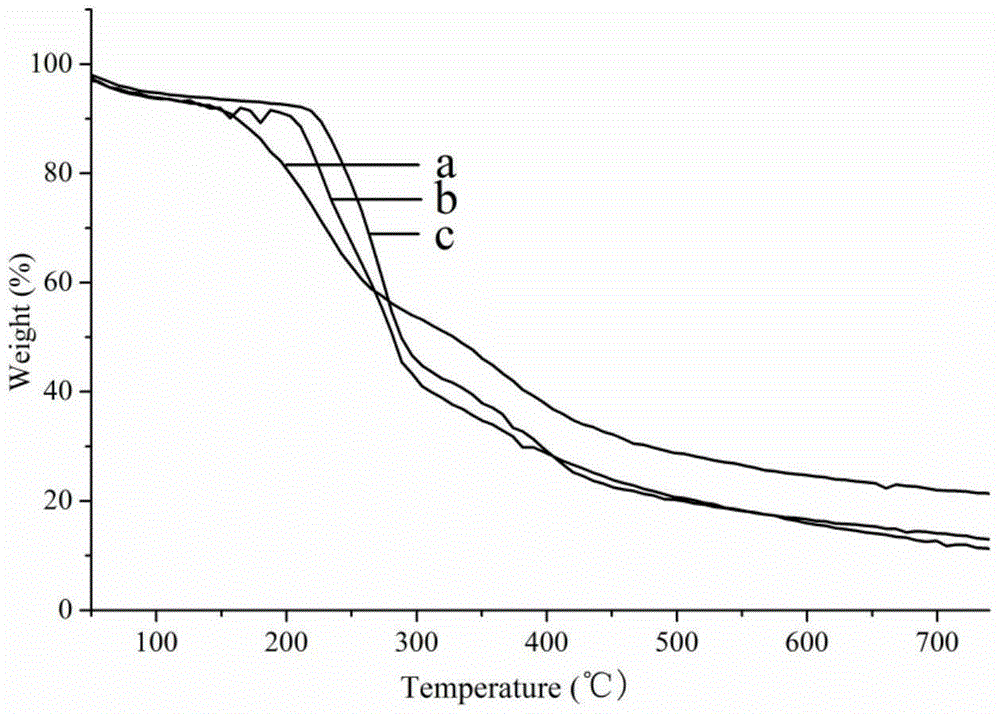

Image

Examples

Embodiment 1

[0027] A modified cellulose nanocrystal and a preparation method thereof, the formula ratio is in parts by weight, and the implementation steps are as follows:

[0028] (1) Disperse 1 part of cellulose nanocrystals into a mixed solution containing triethylamine and N'N-dimethylformamide, add 10 parts of 2-bromoisobutyryl bromide dropwise under nitrogen protection, and React at 50°C for 12 hours; after the reaction, filter and extract to obtain cellulose nanocrystalline bromoisobutyrate;

[0029] (2) Dissolve 20 parts of styrene and 0.5 part of ethyl bromoisobutyrate into anisole, and under nitrogen protection, add 0.1 part of cuprous bromide and 0.2 part of cellulose nanocrystal bromoisobutyrate For the ester, add 0.5 parts of N,N,N,N',N'-pentamethyldivinyltriamine to the reaction system, and react at 80°C for 8 hours; after the reaction, filter, extract, and dry, The modified cellulose nanocrystals were obtained.

Embodiment 2

[0031] A modified cellulose nanocrystal and a preparation method thereof, the formula ratio is in parts by weight, and the implementation steps are as follows:

[0032] (1) Disperse 2 parts of cellulose nanocrystals into a mixed solution containing triethylamine and N'N-dimethylformamide. Under nitrogen protection, add 20 parts of 2-bromoisobutyryl bromide dropwise, and React at 60°C for 18 hours; after the reaction, filter and extract to obtain cellulose nanocrystalline bromoisobutyrate;

[0033] (2) 30 parts of styrene and 0.6 part of ethyl bromoisobutyrate are dissolved in anisole, and under nitrogen protection, 0.2 part of cuprous bromide and 0.3 part of cellulose nanocrystal bromoisobutyrate are added For the ester, add 0.6 parts of N,N,N,N',N'-pentamethyldivinyltriamine to the reaction system, and react at 90°C for 10 hours; after the reaction, filter, extract, and dry, The modified cellulose nanocrystals were obtained.

Embodiment 3

[0035] A modified cellulose nanocrystal and a preparation method thereof, the formula ratio is in parts by weight, and the implementation steps are as follows:

[0036] (1) Disperse 3 parts of cellulose nanocrystals into a mixed solution containing triethylamine and N'N-dimethylformamide, under nitrogen protection, add 30 parts of 2-bromoisobutyryl bromide dropwise, and React at 70°C for 24 hours; after the reaction, filter and extract to obtain cellulose nanocrystalline bromoisobutyrate;

[0037] (2) 50 parts of styrene and 0.7 part of ethyl bromoisobutyrate are dissolved in anisole, and under nitrogen protection, 0.3 part of cuprous bromide and 0.5 part of cellulose nanocrystal bromoisobutyrate are added For the ester, add 0.7 parts of N,N,N,N',N'-pentamethyldivinyltriamine to the reaction system, and react at 100°C for 12 hours; after the reaction, filter, extract, and dry, The modified cellulose nanocrystals were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com