Preparing method for silicon-containing optical anti-reflection polyester film

A polyester film, optical technology, applied in the direction of coating, etc., can solve the problems of monodisperse nano-SiO2, etc., achieve the effect of changing the hydrophobic property and improving the effect of anti-reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

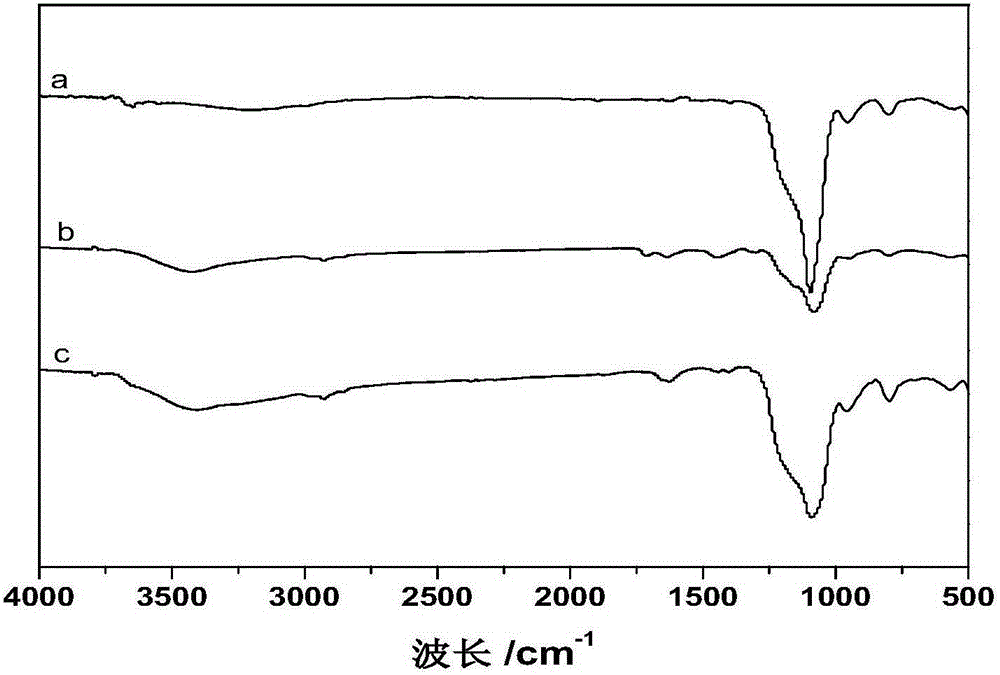

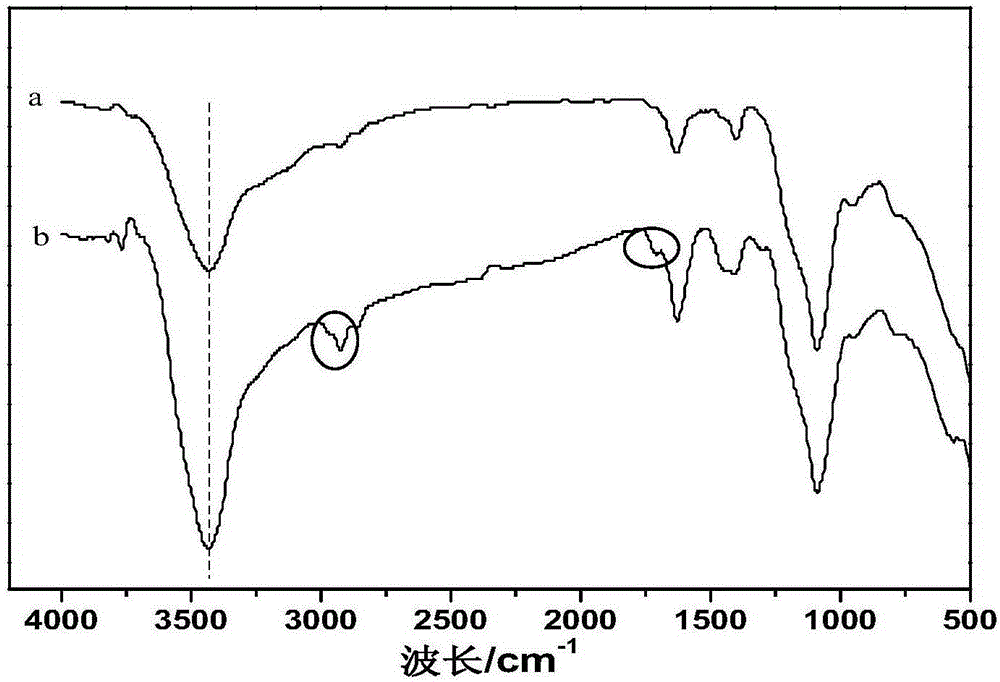

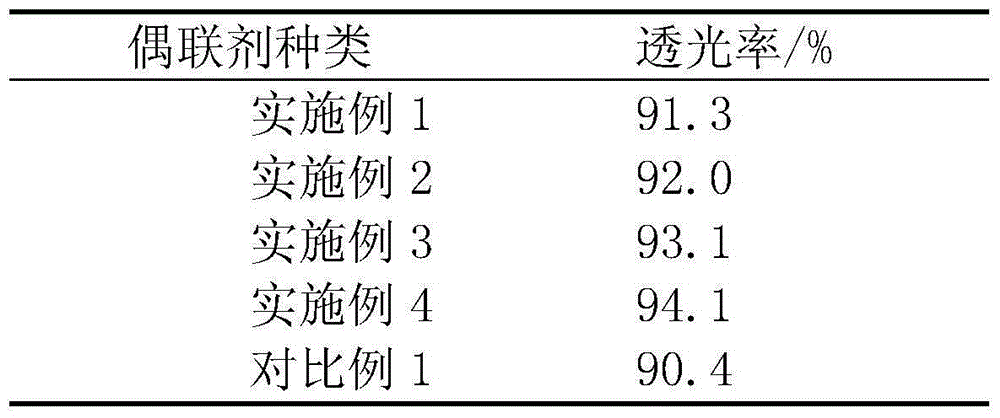

[0027] (1) Prepare 50 ml of absolute ethanol, 3 ml of ammonia water and 5 ml of distilled water in No. 1 beaker, and prepare 50 ml of absolute ethanol and 6 ml of TEOS in No. 2 beaker. Pour the mixed solution in the No. 1 beaker into a dry three-necked flask, place it in an oil bath at 50°C and stir evenly, pour the mixed solution in the No. 2 beaker into a constant pressure dropping funnel, and add slowly drop by drop. After the dropwise addition, react at 50°C for 1 hour, and drop γ-methacryloxypropyltrimethoxysilane (KH570) into the three-necked flask according to the TEOS:silane coupling agent (volume ratio) of 1:6. , and reacted at 50° C. for 4 hours after the dropwise addition was completed. (2) Spin coating and film formation: take out the SiO prepared in step (1) 2 The sol is diluted in different times and then spin-coated on the washed and dried PET film. After a certain heat treatment, the light transmittance is measured. The PET film is 3cm×3cm; the coating time i...

Embodiment 2

[0030] (1) Prepare 50 ml of absolute ethanol, 3 ml of ammonia water and 5 ml of distilled water in No. 1 beaker, and prepare 50 ml of absolute ethanol and 6 ml of TEOS in No. 2 beaker. Pour the mixed solution in the No. 1 beaker into a dry three-necked flask, place it in an oil bath at 50°C and stir evenly, pour the mixed solution in the No. 2 beaker into a constant pressure dropping funnel, and add slowly drop by drop. After the dropwise addition, react at 50°C for 1 hour, add dodecafluoroheptylpropyltrimethoxysilane (G502) dropwise into the three-necked flask according to the TEOS:silane coupling agent (volume ratio) of 1:6, dropwise After completion, the reaction was carried out at 50° C. for 4 hours. (2) Spin coating and film formation: take out the SiO prepared in step (1) 2 The sol is diluted in different times and then spin-coated on the washed and dried PET film. After a certain heat treatment, the light transmittance is measured. The PET film is 3cm×3cm; the coating...

Embodiment 3

[0033] (1) Prepare 50 ml of absolute ethanol, 3 ml of ammonia water and 5 ml of distilled water in No. 1 beaker, and prepare 50 ml of absolute ethanol and 6 ml of TEOS in No. 2 beaker. Pour the mixed solution in the No. 1 beaker into a dry three-necked flask, place it in an oil bath at 50°C and stir evenly, pour the mixed solution in the No. 2 beaker into a constant pressure dropping funnel, and add slowly drop by drop. After the dropwise addition, react at 50°C for 1 hour, and drop γ-methacryloxypropyltrimethoxysilane (KH570) into the three-necked flask according to the TEOS:silane coupling agent (volume ratio) of 1:6. , and reacted at 50° C. for 4 hours after the dropwise addition was completed. (2) Spin coating and film formation: take out the SiO prepared in step (1) 2 The sol is diluted in different times and then spin-coated on the washed and dried PET film. After a certain heat treatment, the light transmittance is measured. The PET film is 3cm×3cm; the coating time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com