High-abrasion-resistance antistatic shoe sole rubber material and preparation method thereof

A rubber material, anti-static technology, applied in the field of rubber materials, can solve the problems of short life, insufficient wear resistance, no wear resistance, etc., to achieve the effect of improving wear resistance, improving antistatic performance, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

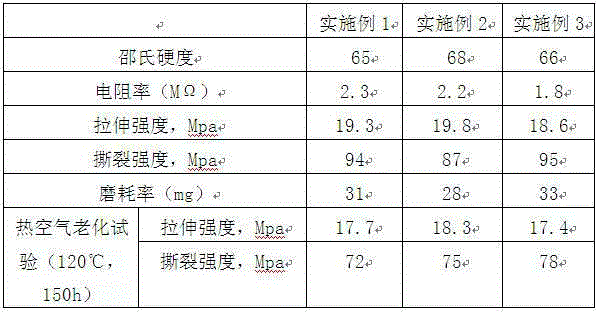

Examples

Embodiment 1

[0015] A high wear-resistant and anti-static sole rubber material, which is prepared from the following raw materials in parts by weight (kg): natural rubber 90, styrene-butadiene rubber 12, coumarone resin 8, trishydroxyethylmethyl quaternary ammonium methylsulfuric acid Salt 4, dibutyloctyl phthalate 7, 3-aminopropyltriethoxysilane 4, 2,6-di-tert-butyl p-cresol 5, triisodecyl trimellitate 2, Cocamidopropyl amine oxide 7, nano-ferric oxide 2, organic montmorillonite 20, nano-zirconium carbide 25, high wear-resistant carbon black 20, paraffin oil 5, tetrabutylthiuram disulfide 3, o-toluene 0.2 base thiourea, 1 sulfur, 4 stearic acid, 6 N-phenyl-1-naphthylamine, 10 basic magnesium carbonate, 5 nanometer zinc oxide.

[0016] A preparation method of a high wear-resistant antistatic shoe sole rubber material, comprising the following steps:

[0017] (1) First put natural rubber, styrene-butadiene rubber, and coumarone resin in a drying oven to dry for 10-15 minutes, then add them...

Embodiment 2

[0022] A high wear-resistant and anti-static sole rubber material, which is prepared from the following raw materials in parts by weight (kg): natural rubber 100, styrene-butadiene rubber 14, coumarone resin 10, trishydroxyethylmethyl quaternary ammonium methylsulfuric acid Salt 5, dibutyloctyl phthalate 8, 3-aminopropyltriethoxysilane 5, 2,6-di-tert-butyl p-cresol 6, triisodecyl trimellitate 2.5, Cocamidopropyl amine oxide 8, nano-ferric oxide 3, organic montmorillonite 22.5, nano-zirconium carbide 30, high wear-resistant carbon black 25, paraffin oil 6, tetrabutylthiuram disulfide 3.5, o-toluene 0.3 base thiourea, 1.5 sulfur, 4.5 stearic acid, 8 N-phenyl-1-naphthylamine, 11 basic magnesium carbonate, and 6 nanometer zinc oxide.

[0023] The preparation method is the same as in Example 1.

Embodiment 3

[0025] A high wear-resistant and anti-static shoe sole rubber material, which is prepared from the following raw materials in parts by weight (kg): natural rubber 110, styrene-butadiene rubber 16, coumarone resin 12, trihydroxyethylmethyl quaternary ammonium methylsulfuric acid Salt 6, dibutyloctyl phthalate 9, 3-aminopropyltriethoxysilane 6, 2,6-di-tert-butyl p-cresol 7, triisodecyl trimellitate 3, Cocamidopropyl amine oxide 9, nano-ferric oxide 4, organic montmorillonite 25, nano-zirconium carbide 35, high wear-resistant carbon black 30, paraffin oil 7, tetrabutylthiuram disulfide 4, o-toluene 0.4 base thiourea, 2 sulfur, 5 stearic acid, 10 N-phenyl-1-naphthylamine, 12 basic magnesium carbonate, and 7 nanometer zinc oxide.

[0026] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com