Inorganic mineral powder filling foaming masterbatch and preparation method thereof

A technology of inorganic mineral powder and foaming masterbatch, which is applied in the preparation of filling foaming masterbatch and in the field of plastic processing, which can solve the problems of high cost and achieve compact appearance, reduce production cost and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] ① Foaming agent activation raw material formula:

[0031] It is prepared by mixing 25 parts of foaming agent azodicarbonamide, 1.5 parts of dicumyl peroxide, 15 parts of stearic acid and 58.5 parts of liquid paraffin.

[0032] ② Filling foam masterbatch raw material formula:

[0033] 80 parts of heavy calcium carbonate, 8 parts of polyethylene, 4 parts of polyethylene wax, 1 part of aluminate coupling agent, 0.6 part of stearic acid, 0.4 part of zinc stearate, 6 parts of activated foaming agent.

[0034] ① Preparation of foaming agent activation:

[0035] The foaming agent azodicarbonamide, dicumyl peroxide, stearic acid and liquid paraffin were mixed and dispersed at about 95°C with an emulsifier at high speed for 12 minutes to obtain an activated foaming agent;

[0036] ② Preparation of filling foam masterbatch:

[0037] First, add the heavy calcium carbonate powder into a high-speed mixer and stir to above 100°C to fully remove the moisture in the heavy calcium ca...

Embodiment 2

[0041] The preparation method of this embodiment is the same as that of Example 1, except that the polypropylene and the foaming masterbatch prepared in this embodiment are mixed at a high speed at a mass ratio of 80:40 when preparing the inorganic mineral powder filled polypropylene micro-foaming material Mixing in the machine for 4 minutes, and then injection molding to obtain polypropylene micro-foaming material.

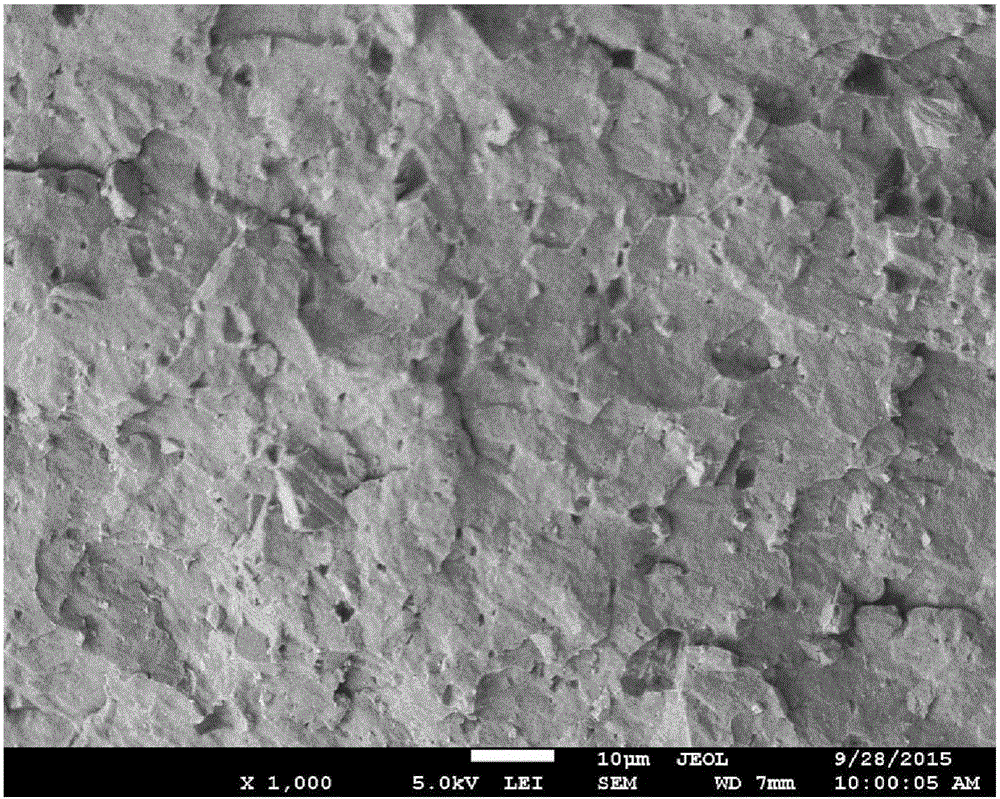

[0042] The photo of the cross-sectional cell structure of the heavy calcium carbonate powder filled with polypropylene micro-foaming material prepared in this example is shown in figure 2 . The density of the filled expanded polypropylene unfired material is 1.06g / cm 2 , the density of the filled polypropylene material prepared without foaming agent is 1.12g / cm 2 .

Embodiment 3

[0044] ① Foaming agent activation raw material formula:

[0045] It is prepared by mixing 28 parts of foaming agent azodicarbonamide, 1.6 parts of dicumyl peroxide, 12 parts of stearic acid and 58.4 parts of liquid paraffin.

[0046] ② Filling foam masterbatch raw material formula:

[0047] 75 parts of talcum powder, 12 parts of polyethylene, 6 parts of polyethylene wax, 1.5 parts of aluminate coupling agent, 1 part of stearic acid, 0.5 parts of zinc stearate, and 4 parts of activated foaming agent.

[0048] ① Preparation of foaming agent activation:

[0049] The foaming agent azodicarbonamide, dicumyl peroxide, stearic acid and liquid paraffin were mixed and dispersed at about 100°C with an emulsifier at high speed for 14 minutes to obtain an activated foaming agent;

[0050] ② Preparation of filling foam masterbatch:

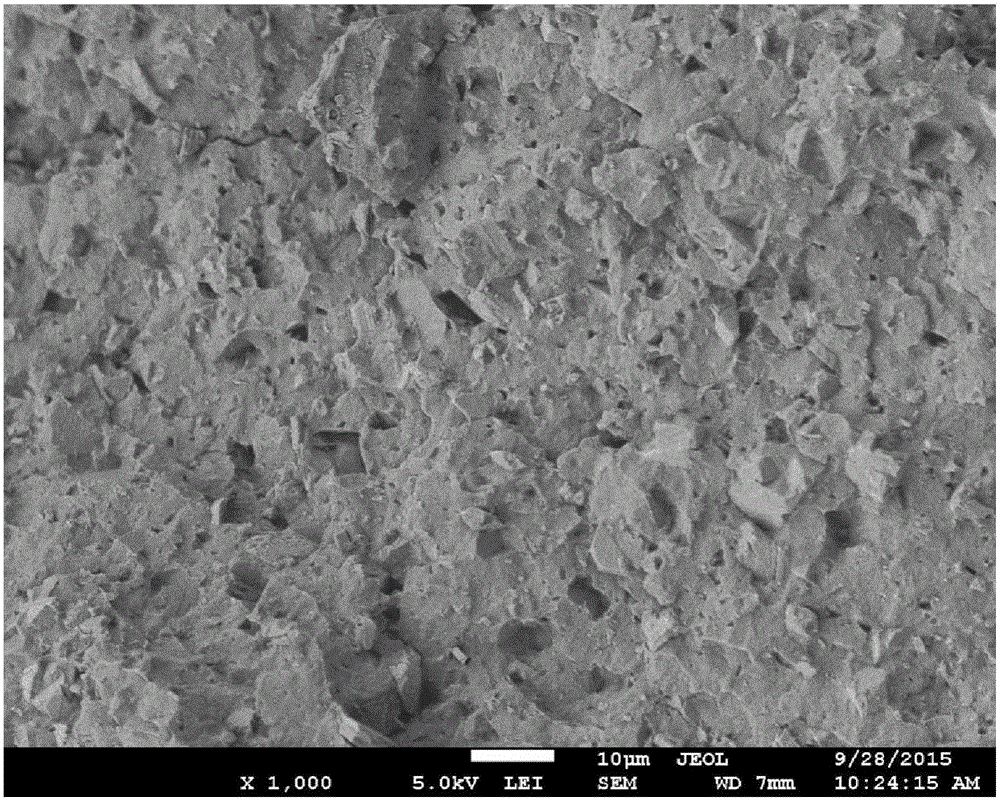

[0051] First, add the talc powder into the high-speed mixer and stir to above 100°C to fully remove the moisture in the talc powder; then add the coupling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com