Organosilicon coating

A silicone coating and silicone technology, applied in coatings, adhesives, etc., can solve problems such as inability to adhere to coatings, and achieve the effects of fast curing speed, reduction of processes, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

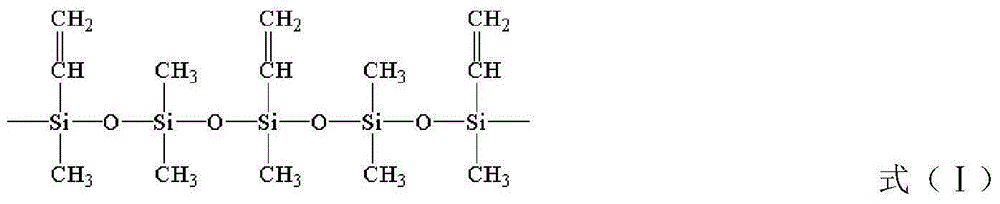

[0051] The methyl vinyl silicone polymer in the following examples is one or more of REN50, REN60 or REN80 from Wacker, Germany. The methyl phenyl silicone polymer is BYK-322 and BYK-164 of BYK Chemical in Germany.

[0052] Hydrogen-containing silicone oil is one or more of AK50, AK100, AK350 and AK500 from Wacker of Germany.

[0053] The model of the fluorine-containing acrylate monomer is Viscoat 8F or Viscoat 8FM, purchased from Osaka Organic Chemical Industry Co., Ltd.

[0054] The inhibitor is one or more paint inhibitors purchased from Shenzhen Osbon New Material Co., Ltd. The deblocking temperature of the inhibitor on the metal catalyst is ≥80°C.

[0055] Additives are leveling agents, anti-settling agents, wetting and dispersing agents, one or more of the series of additives such as Desiballone from Japan, Dow Corning from the United States, and BYK from Germany.

[0056] The metal catalyst is one or more of PL-3 and / or PL-4 of Toshiba Japan.

[0057] The organic solvent is one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com