Phase transfer agent for removing heavy metals from medium and low temperature coal tar, and application thereof

A technology of low-temperature coal tar and phase transfer agent, which is applied in tar processing by distillation method and tar refining by chemical method, etc., can solve the problems of few phase transfer agents and few demetallizing agents in the method of removing, and achieves a good solution. Conducive to safe, stable and long-term operation, reduced processing capacity, and reduced process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

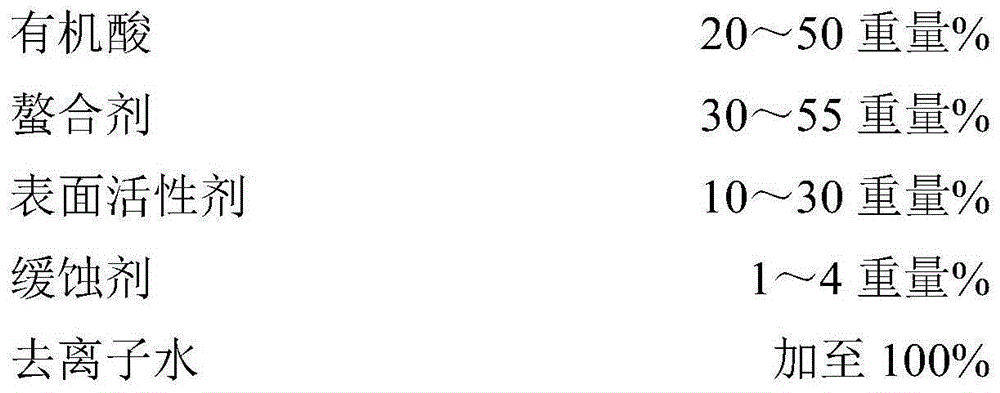

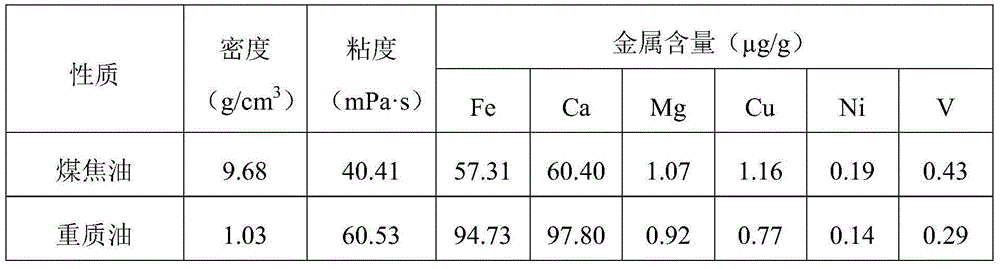

[0038] The phase transfer agent used in this embodiment is made up of the raw materials of following mass ratio:

[0039]

[0040] Wherein: organic acid is the mixed solution that the malonic acid of 38% by weight, the maleic acid of 33% by weight and the tartaric acid of 29% by weight are formed; A mixed solution composed of bisphosphonic acid; the surfactant is a mixed solution composed of 70% by weight of polypropylene glycol and 30% by weight of diglycolamine, and the number-average molecular weight of polypropylene glycol is 1000-2500; the corrosion inhibitor is potassium iodide .

[0041] The conditions of electro-desalting are: electro-de-salting temperature is 120°C, electric field strength is 1800v / cm, residence time is 30min, and the injection amount of phase transfer agent is 200μg / g, that is, 200μg of phase transfer agent per gram of heavy oil, note The amount of water is 8% of the mass of heavy oil.

[0042] In this embodiment, the total iron removal rate and...

Embodiment 2

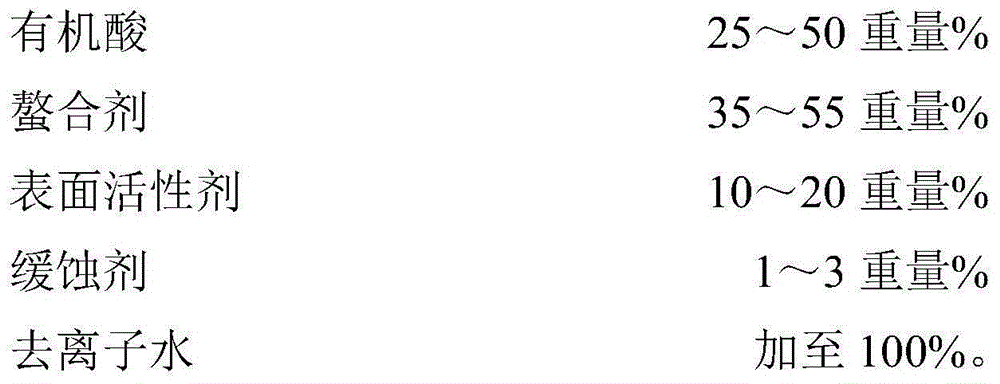

[0044] The phase transfer agent used in this embodiment is made up of the raw materials of following mass ratio:

[0045]

[0046]

[0047] Wherein: the organic acid is a mixture of 35% by weight of malonic acid, 35% by weight of maleic acid and 30% by weight of tartaric acid; the chelating agent is 70% by weight of aminotriacetic acid and 30% by weight of ethylene glycol A mixed solution composed of amine tetramethylene phosphonic acid; the surfactant is a mixed solution composed of 75% by weight of polypropylene glycol and 25% by weight of diglycolamine, and the number average molecular weight of polypropylene glycol is 1000-2500; corrosion inhibitor Potassium iodide is used.

[0048] The conditions of electro-desalting are: electro-de-salting temperature is 120°C, electric field strength is 1800v / cm, residence time is 30min, and the injection amount of phase transfer agent is 200μg / g, that is, 200μg of phase transfer agent per gram of heavy oil, note The amount of wa...

Embodiment 3

[0051] The phase transfer agent used in this embodiment is made up of the raw materials of following mass ratio:

[0052]

[0053] Wherein: organic acid is the mixed solution that the malonic acid of 36% by weight, the maleic acid of 35% by weight and the tartaric acid of 29% by weight form; A mixed solution composed of trisodium diamine triacetic acid and 40% by weight of aminotrimethylene phosphonic acid; the surfactant is 80% by weight of polypropylene glycol and 20% by weight of diglycolamine; the corrosion inhibitor is potassium iodide.

[0054] The conditions of electro-desalting are: electro-de-salting temperature is 120°C, electric field strength is 1800v / cm, residence time is 30min, and the injection amount of phase transfer agent is 300μg / g, that is, 300μg of phase transfer agent per gram of heavy oil, note The amount of water is 8% of the mass of heavy oil.

[0055] In this embodiment, the total iron removal rate and calcium removal rate of the final coal tar we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com