A New Axial Flow Fan Static Blade Adjustment System

An axial flow fan and adjustment system technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of servo valve spool stuck, production line shutdown, large volume, etc., and achieve good energy saving effect and energy loss. Less and more efficient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

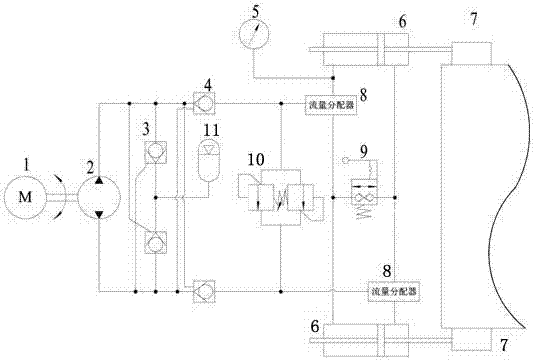

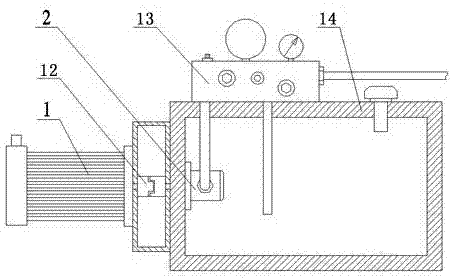

[0023] As shown in the figure, a new type of axial flow fan stator blade adjustment system includes a servo motor 1, a bidirectional quantitative gear pump 2, and an oil tank 14. The bidirectional quantitative gear pump 2 is fixed inside the oil tank 14 and driven by the servo motor 1 to rotate. It also includes two hydraulic cylinders 6 and adjusting oil cylinders 7 respectively connected thereto for adjusting the vane angle. The two hydraulic cylinders 6 are respectively connected to the adjusting oil cylinders 7 through couplings 12 .

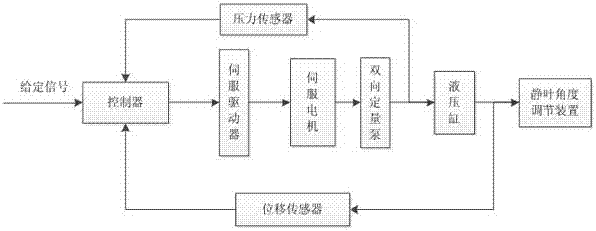

[0024] Displacement sensors are arranged inside the two hydraulic cylinders 6, which are used to detect the displacement of the piston rod of the hydraulic cylinder and adjust the position of the hydraulic cylinder after the signal is fed back to the controller; A pressure sensor is provided to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com