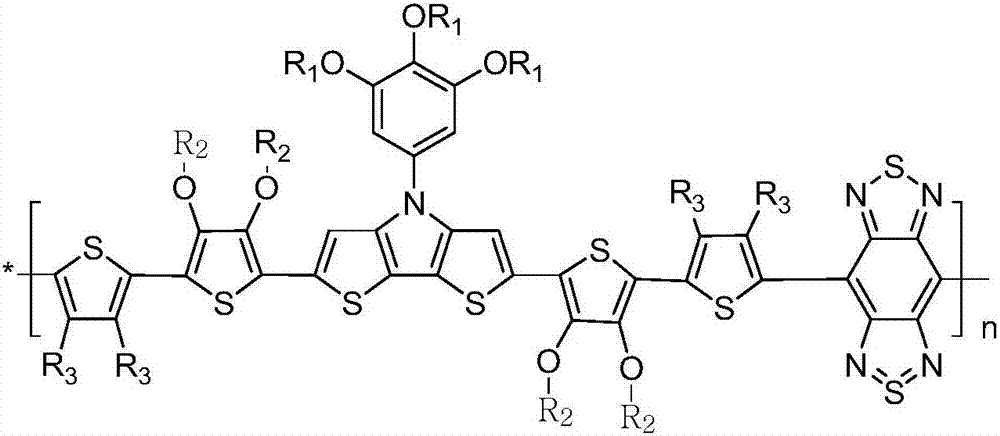

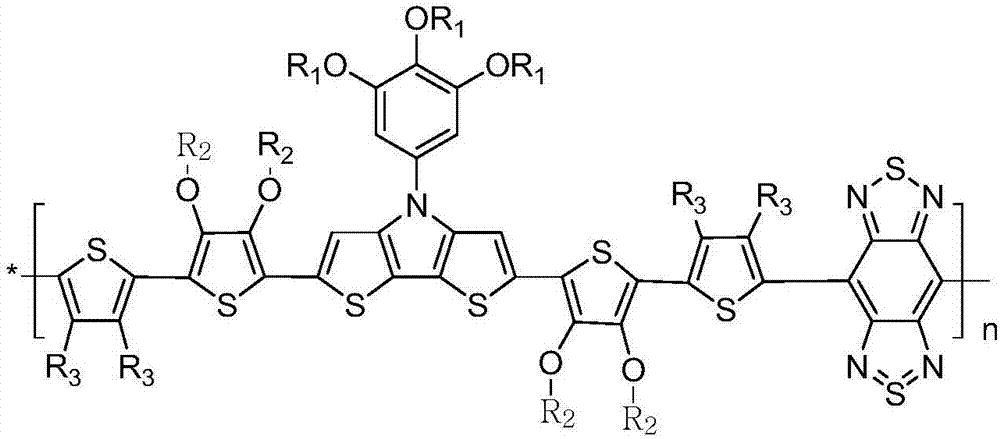

A kind of long-wave absorbing copolymer donor material for photoactive layer of polymer solar cell

A technology of solar cells and photoactive layers, which is applied in electric solid devices, circuits, photovoltaic power generation, etc., can solve the problems of low degree of conjugation, low band gap, poor solubility, etc., so as to enhance the solubility and processing performance, improve Conjugation degree, effect of high conjugation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

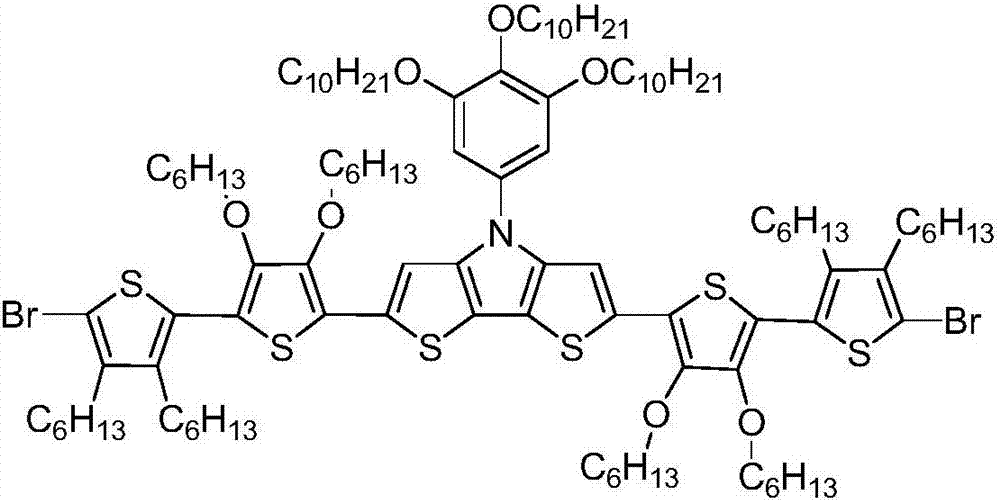

[0021] (1) Dibromo(bithiophene)-N-trialkoxyphenylbisthienopyrrole

[0022]

[0023] Add bis(bithiophene)-N-trialkoxyphenylbisthienopyrrole (2.0mmol), chloroform (60mL) and acetic acid (12mL) into a 250mL round bottom flask, add N-bromosuccinyl Amine (NBS, 2.1 mmol), the reaction mixture was stirred at room temperature for 3 h. Dichloromethane (100 mL) was then added to the reaction mixture, and the organic layer was dried over anhydrous magnesium sulfate after washing with water. The solvent was removed under reduced pressure, and the obtained light brown solid was the target product with a yield of 95%.

[0024] (2) Bis(2-trimethyltinthiophene)-N-trialkoxyphenylbisthienopyrrole

[0025]

[0026] Dibromo(bithiophene)-N-trialkoxyphenylbisthienopyrrole (1.22mmol) was dissolved in tetrahydrofuran (150mL), the reaction system was cooled to -78°C, and n-BuLi (2.68mmol ), stirred for 1 h, warmed to room temperature and then stirred for 2 h, cooled to -78 ° C again, and adde...

Embodiment 2

[0041] (1) Dibromo(bithiophene)-N-trialkoxyphenylbisthienopyrrole

[0042]

[0043] Add bis(bithiophene)-N-trialkoxyphenylbisthienopyrrole (2.0mmol), chloroform (60mL) and acetic acid (16mL) in a 250mL round bottom flask, add N-bromosuccinyl Amine (NBS, 2.2 mmol), the reaction mixture was stirred at room temperature for 0.5 h. Dichloromethane (180 mL) was then added to the reaction mixture, and the organic layer was dried over anhydrous magnesium sulfate after washing with water. The solvent was removed under reduced pressure to obtain a solid which was the target product with a yield of 91%.

[0044] (2) Bis(2-trimethyltinthiophene)-N-trialkoxyphenylbisthienopyrrole

[0045]

[0046] Dibromo(bithiophene)-N-trialkoxyphenylbisthienopyrrole (1.22mmol) was dissolved in tetrahydrofuran (100mL), the reaction system was cooled to -78°C, and n-BuLi (2.65mmol ) in n-hexane, stirred for 0.5h, slowly warmed up to room temperature and then stirred for 2h, cooled to -78°C again, ...

Embodiment 3

[0052] (1) Dibromo(bithiophene)-N-trialkoxyphenylbisthienopyrrole

[0053]

[0054] Add bis(bithiophene)-N-trialkoxyphenylbisthienopyrrole (2.0mmol), chloroform (60mL) and acetic acid (10mL) into a 250mL round bottom flask, add N-bromosuccinyl Amine (NBS, 2.1 mmol), the reaction mixture was stirred at room temperature for 2 h. Dichloromethane (100 mL) was then added to the reaction mixture, and the organic layer was dried over anhydrous magnesium sulfate after washing with water. The solvent was removed under reduced pressure, and the obtained light brown solid was the target product with a yield of 90%.

[0055] (2) Bis(2-trimethyltinthiophene)-N-trialkoxyphenylbisthienopyrrole

[0056]

[0057] Dibromo(bithiophene)-N-trialkoxyphenylbisthienopyrrole (1.22mmol) was dissolved in tetrahydrofuran (150mL), the reaction system was cooled to -78°C, and n-BuLi (2.7mmol ), stirred for 1 h, warmed to room temperature and then stirred for 2 h, cooled to -78 ° C again, and added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com