Self-lubricating polypropylene material and preparation method thereof

A polypropylene material and self-lubricating technology, which is applied in the field of self-lubricating polypropylene material and its preparation, can solve the problems of large aspect ratio and surface energy, small diameter of carbon nanotubes, and inability to disperse uniformly, so as to improve the interfacial phase Capacitance, excellent mechanical properties, anti-friction and self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

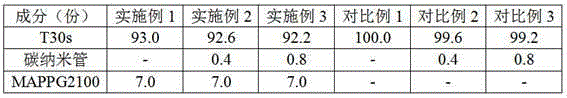

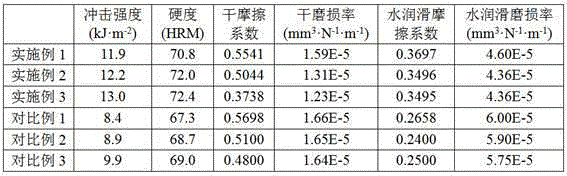

[0016] Below in conjunction with example, the present invention is described in further detail:

[0017] In the formulation of the composite material in the example, the polypropylene is produced by Fujian United Petrochemical Co., Ltd., and the trade name is T30s. The carbon nanotubes are prepared by chemical vapor deposition, ground into fine powder with a planetary ball mill, and then the catalyst carrier is removed with hydrofluoric acid, Ni, Al and amorphous carbon are removed with 65% (v / v) nitric acid, It is then boiled with sulfuric acid and nitric acid (volume ratio 3:1), washed until nearly neutral and vacuum-dried. The diameter is 18.4-45.2nm and the length is 0.9-3.0μm. The compatibilizer is maleic anhydride grafted polypropylene, produced by Shanghai Yangli Electromechanical Technology Co., Ltd., the model is MAPPG2100, the grafting rate is ≥ 1.0%, the melting index is ≥ 80g / 10min, and the softening point is 153°C.

[0018] Weigh the raw materials according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com