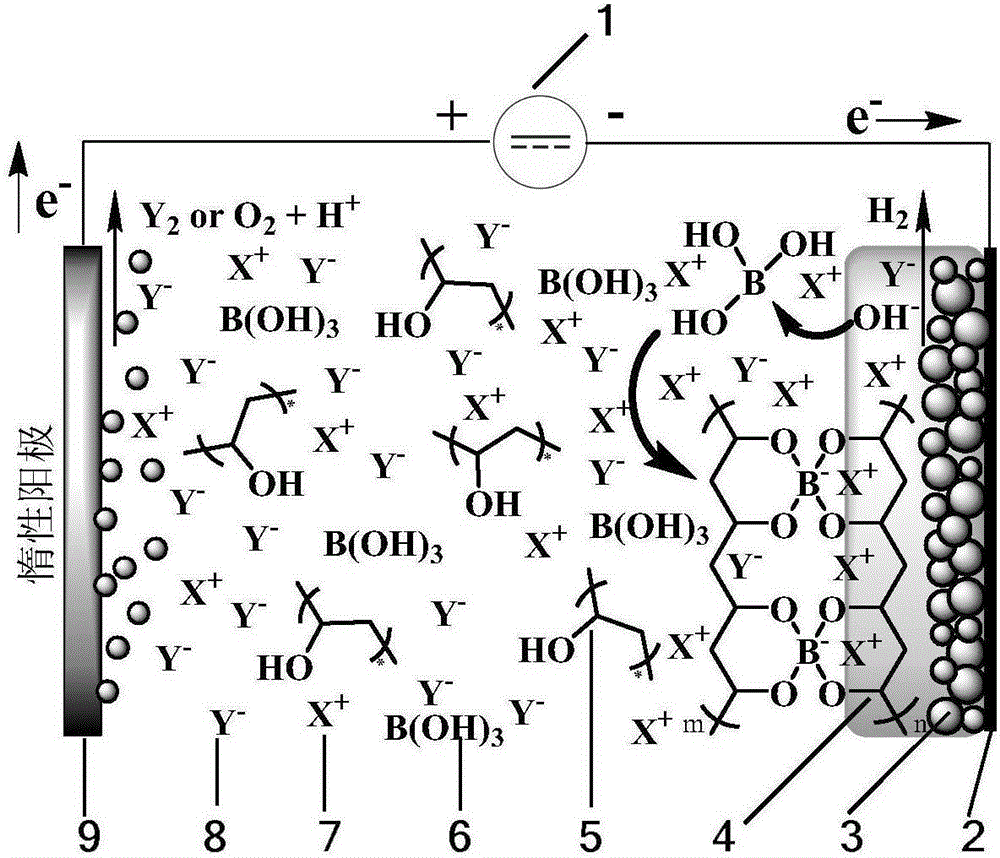

Method for directly preparing polyvinyl borate complexing water gel electrolytes on surface of electrode

A technology of polyvinyl alcohol borate and electrode surface, which is applied in hybrid capacitor electrolytes, circuits, electrical components, etc., can solve the problems of high internal resistance of electrical devices, poor electrode contact, and long preparation cycle, so as to improve conductivity, Avoid large power consumption, reduce energy consumption and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 2 parts of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99%, 0.5 parts of boric acid and 7 parts of potassium chloride into 100 parts of deionized water, stir and heat up to 95°C to dissolve and form a uniform solution, and then cool down to Standby at 50°C;

[0038] The activated carbon supercapacitor electrode active material with a thickness of 0.8mm pressed with 10wt% polytetrafluoroethylene binder and 90wt% activated carbon with a specific surface area of 1000㎡ / g was attached to one side of the stainless steel collector, and the other side of the stainless steel collector One side is covered with insulating tape to make a supercapacitor electrode;

[0039] First, the fabricated supercapacitor electrode is used as the cathode, and the graphite rod is used as the anode, and placed in the electroplating pool, then the configured electrogel solution is placed in the electroplating pool, and a 2.5V voltage is applied bet...

Embodiment 2

[0041] Add 2 parts of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99%, 0.6 parts of boric acid and 7 parts of sodium chloride into 100 parts of deionized water, stir and heat up to 95°C to dissolve and form a uniform solution, and then cool down to Standby at 50°C;

[0042] The activated carbon supercapacitor electrode active material with a thickness of 0.8mm pressed with 5wt% polytetrafluoroethylene binder and 95wt% activated carbon with a specific surface area of 1000㎡ / g was attached to one side of the stainless steel collector, and the other side of the stainless steel collector One side is covered with insulating tape to make a supercapacitor electrode;

[0043] First, the fabricated supercapacitor electrode is used as the cathode, and the gold sheet is used as the anode, and placed in the electroplating pool, then the configured electrogel solution is placed in the electroplating pool, and a 2.5V voltage is applied between t...

Embodiment 3

[0045] Add 0.5 parts of polyvinyl alcohol with a polymerization degree of 6500 and an alcoholysis degree of 88%, 1.0 parts of boric acid and 20 parts of lithium chloride into 100 parts of deionized water, stir and heat up to 105°C to dissolve and form a uniform solution, and then cool down to Standby at 70°C;

[0046] Mix 5wt% polyvinylidene fluoride binder, 5wt% acetylene black conductive agent and 90wt% manganese dioxide powder and evenly spread and press on one side of the foamed nickel collector, and the other side of the foamed nickel collector is covered with insulation The adhesive tape is made into supercapacitor electrodes;

[0047] First, the fabricated supercapacitor electrode is used as the cathode, and the platinum sheet is used as the anode, and placed in the electroplating pool, then the configured electrogel solution is placed in the electroplating pool, and a 2.0V voltage is applied between the cathode and the anode. Voltage, take it out after 3min, the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com